Get a Quote

SEPPES Hydraulic Dock Leveler – Safe, Stable, Efficient Loading

Heavy-duty platform designed for fast and safe truck loading across all warehouse types.

Product Overview

Welcome to the world of Logistics – Introducing our Loading Dock Leveler, a key component of any logistics warehouse designed for the agile loading and unloading of freights. Your Dock Leveler moves in unison with the Control system, Electro-Hydraulic Power Unit, Adjusting Plate and Tongue plate to effectively eliminate the height variations between the bottom of the trailers and the loading bay, creating a seamless transition between the trailers and docks. This significantly enhances the loading and unloading operational efficiency.

The retraction of the Drop-Down Side Guards is automatic, enhancing safety. Dynamic Load Rating is 6.3T, Static Load Rating is 13.6T. The Dock Leveler offers the Modern Logistics Industry an unparalleled operational safety, logistics efficiency enhancement, and operational cost reduction.

Contact us and learn more about our products !

Key Features of SEPPES Hydraulic Dock Leveler

Adjustable Customizable Lip Structure

We have increased the lip thickness adjustments to 40 and 50 centimeters. The tread plate is also non-slip, anti-corrosive, and engineered for high load strength. The reinforced lip contour ensures long term stability and durability during loadings.

Improved Load Capacity

Available in 6T / 8T / 10T, with a 6.3T dynamic load and a 13.6T static load to satisfy the majority of industrial demand.

Sophisticated Control System

Our control system smoothly bridges height differences between trucks and docks, ensuring the system is stably supported and safe from overload while moving.

Improved Level of Protection

The dock leveler has a hydraulic system with an anti-fall valve to ensure secure, stable operation of the leveler.

Detail Display Of SEPPES Hydraulic Dock Leveler

Lip Details

Innovative double 5° arch bridge type reinforced tongue plate design technology.

Side Seal

Both sides are sealed with rubber strips to prevent dust from entering.

.jpg)

Dual hydraulic pump(Optional)

Carrying a large weight, smoother transportation.

Motherboard stiffener

Ensure that the support of the platform table is more stable and powerful.

Hydraulic Dock Leveler Structure

- Tail lip

- Side curtain safety baffle

- Lip plate cylinder

- Platform support steel

- Lifting cylinder

- Hydraulic pump

- Sealing rubber strip

- Yellow and black warning strips

- Pedestal

- Control unit

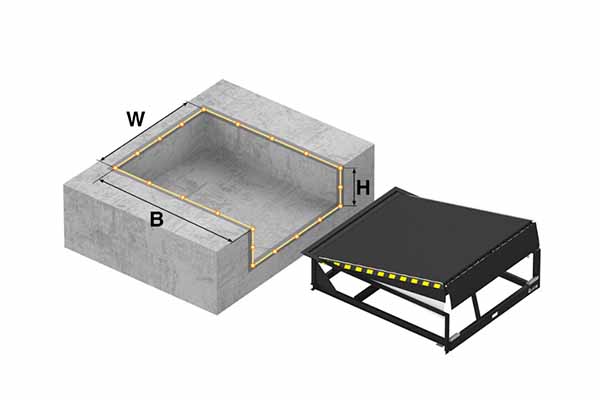

Installation conditions

About the dock leveler, we can design and offer you professional 3D and CAD drawings according to installation conditions. It’s very easy to install a dock leveler when the pit is ready well. It also makes your logistic work more convenient.

Our Dock Leveler Project Cases

Dubai -Plastic Manufacturing Company

The client is a big player in pharmaceutical logistics in the area. They use our dock leveler to integrate their logistics process with their production line, allowing the customer to efficiently deliver plastic items to the production line, streamline the process, and fulfill market demands.

Indonesia -Material Handling Warehouse

The customer runs one of the biggest retail businesses in Indonesia, with several distribution centers across the country. They picked our dock leveler for the optimal distribution of their products and enhanced customer experience. This customer has improved their business logistics, lowered their costs, and gained faster service.

America -International Logistics Company

Some clients are the worldwide distribution and logistic centers that move thousands of tons of cargo every day. Dock levelers help ensure quick transshipment and distribution of goods by providing efficient and safe loading processes. Our dock levelers are conveniently height adjustable to different trucks and cargo sizes to better boost productivity.

Common Types of Dock Levelers

Learn about some of the most common dock levelers and note unusual designs offered by some manufacturers.

Mechanical Dock Leveler

Mechanical dock levelers are built for easy usability and durability. They are a sound choice for facilities with moderate traffic and basic operational needs. The levelers work using a spring system and a manual pull chain. Using no electricity helps reduce operational costs. Based on the design, they require very little maintenance and are trusted easy performers. They are the best choice for facilities that require dock levelers, but also have lower traffic or are on a tight budget.

Edge of Dock Levelers

For loading areas not too big, edge of dock levelers work perfectly. Edge of dock levelers work well for facilities with smaller budgets and space, and their height adjustment range is great. Compared to dock boards, edge of dock levelers provide a safer and more ergonomic footing and are much better at eliminating fall-related injuries. Edge of dock levelers are intended for standard loading dock heights. While a lot of businesses have edge of dock levelers, their limitations and tolerances are still huge, and their prices are still affordable, and with great safety features, edge of dock levelers are still a great option for businesses.

Vertical Dock Leveler

Vertical dock levelers feature a unique configuration and design allowing for an even more robust and effective seal when stored upright and under the dock. Although these levelers are hydraulic and vertical when not in use, they will stay vertically aligned. Because of these vertical design features, the levelers seal the door opening during the raised position. This prevents the loss of conditioned air and keeps the warehouse environment efficient. Vertical dock levelers help logistics companies keep a tight, controlled internal environment and reduce energy loss. This is more of a concern for companies that prioritize cleanliness and energy efficiency.

Loading Dock Scissor Leveler

Scissor lift levelers at loading docks are dependable for the varied heights of trucks. The scissor lift mechanism provides stable elevation adjustments. The levelers are hydraulic, allowing easy and safe operation, ideal for busy working conditions. Levelers provide efficient loading and unloading, even at varying heights.

Telescopic Dock Leveler

Vertical dock levelers feature a unique configuration and design allowing for an even more robust and effective seal when stored upright and under the dock. Although these levelers are hydraulic and vertical when not in use, they will stay vertically aligned. Because of these vertical design features, the levelers seal the door opening during the raised position. This prevents the loss of conditioned air and keeps the warehouse environment efficient. Vertical dock levelers help logistics companies keep a tight, controlled internal environment and reduce energy loss. This is more of a concern for companies that prioritize cleanliness and energy efficiency.

Resources on Hydraulic Dock Leveler

Working with 4200+ global clients

We have authentic and authoritative certificates

Why is the product quality of many brands not up to standard? Because none of what they show you is a real certificate. Our certificates are authentic. You can request a report from us.

Frequently Asked Questions About SEPPES Dock Leveler

What is a SEPPES dock leveler?

A SEPPES dock leveler makes it easy for operators to load or unload items because it covers the gap between a truck or trailer and the loading dock. The leveler is a mechanical or hydraulic platform that allows for a seamless and secure operation.

What types of dock levelers does SEPPES offer?

SEPPES dock levelers include:

- Hydraulic Dock Levelers: Are the most seamless and efficient option, but the most costly.

- Mechanical Dock Levelers: Cost the least and are the most rudimentary because they are manually operated.

- Air-Powered Dock Levelers: Use an airbag for simple operation.

- Edge-of-Dock Levelers: Compact and work best for smaller docks.

What are the key benefits of SEPPES dock levelers?

Some Benefits Include:

- Improved safety during loading and unloading.

- Improved efficiency with less downtime.

- Long lasting, high quality construction.

- Tailored to specific dock requirements.

Are SEPPES dock levelers customizable?

Yes, SEPPES dock levelers are customizable to an organization’s specific dimensional, weight, and action requirements, as well as additional safety and protective features such as safety lips, and weather seals.

What safety features are included in SEPPES dock levelers?

SEPPES dock levelers have:

- Anti-slip surfaces

- Roll-off protection

- Emergency stops for hydraulic models

- Must use maintenance struts when servicing

How do I maintain a SEPPES dock leveler?

Regular maintenance requirements include:

- Inspect for wear and tear

- Lubricate moving parts

- Check hydraulic/mechanical systems

- Confirm alignment is consistent and components are functional

What is the weight capacity of SEPPES dock levelers?

Dock levelers by SEPPES come in many models with different weight capacities which range from 6,000 lbs to 40,000lbs or beyond, depending on the levelers’ customization.

How do I choose the right SEPPES dock leveler for my facility?

Things to consider include the following:

Types of vehicles and loads that are handled.

Distance in height between the dock and the vehicles.

Operational needs and budget of the facility.

Space limitations and installation needs.