With the rapid development of the global economy, the logistics industry is facing unprecedented challenges. Enterprises often need to remodel their existing warehouses to improve logistics efficiency to meet growing business demands. In this paper, we will explore how to optimize logistics operations by efficiently retrofitting warehouses and adding loading dock equipment to provide solid logistical support for sustained business growth.

Pre-planning and Needs Analysis

Before undertaking a warehouse renovation, the first task is to define the goals and needs of the renovation. This step is critical to the success of the entire project. Companies need to analyze the need for the number, size, and load capacity of additional loading platforms based on factors such as projected business growth, type of goods, and specifications of transport vehicles. This stage of the process will have a direct impact on the accuracy and effectiveness of the subsequent design and construction.

Warehouse dock conversion to add loading dock equipment design and programme development

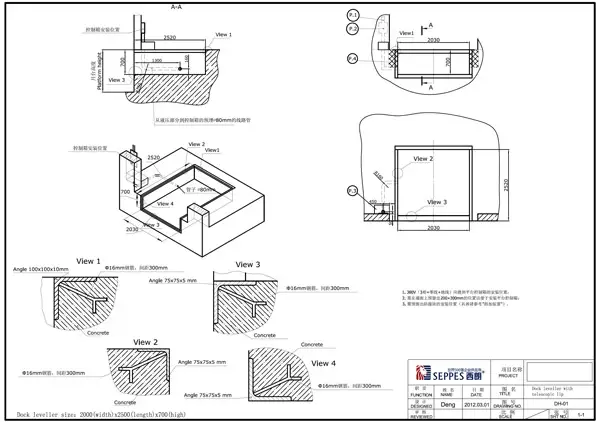

Design program: After defining the requirements, the next step is to develop a specific design program. This includes determining parameters such as the exact location, size, and height of the loading platform. The design must ensure that the loading platform is seamlessly integrated with the warehouse entrance and internal logistics aisles to reduce the time and cost of goods handling. At the same time, safety factors must also be taken into account, such as non-slip design and anti-collision facilities to safeguard the safety of staff.

Technical selection: Choosing the right type of unloading platform is the key to technical selection. Common types of unloading platforms include fixed, mobile and along-the-edge. Companies can make choices based on equipment durability, maintenance costs, and energy efficiency. For example, fixed unloading platforms are suitable for warehouses with a high and steady flow of goods, while mobile unloading platforms and RMs are suitable for situations that require flexibility in adjusting the unloading area.

Procurement and Installation: After completing the design and program development. The enterprise needs to select the right unloading platform according to the demand and carry out the foundation construction. After the construction is completed, the unloading platform and its supporting equipment installation and commissioning. At this stage, it is vital to ensure that all equipment is functioning properly and meets safe operating requirements.

Renovating the warehouse and adding a dock leveler is a complex systematic project. Which involves several aspects such as preliminary planning, design, and construction. Through scientific and rational planning, refined construction management. And continuous operation optimization, companies can effectively improve the unloading capacity and overall operational efficiency of the warehouse. This can not only meet the current business needs but also for the future development of enterprises to lay a solid logistics foundation.