In modern industrial logistics scenarios, unloading areas are the most frequent locations for equipment operation and personnel interaction, and are also key areas with a high incidence of safety accidents. Forklifts frequently enter and exit, large trucks reverse to load and unload, and personnel move back and forth… These factors determine that unloading areas must be equipped with scientific and reliable protective devices. Among these, flexible barriers are gradually replacing traditional rigid protective devices and becoming the preferred choice in high-frequency operation environments.

Why are flexible barriers more suitable for loading docks?

Loading areas not only need to effectively separate vehicle and pedestrian traffic zones. But also absorb energy and protect vehicles and facilities in the event of a collision. The elastic design of flexible barriers excels in this regard:

Impact absorption: Flexible barriers combine high-molecular-weight elastic materials with steel core support structures, offering exceptional deformation recovery capabilities. They can effectively absorb impact forces exceeding 2 tons, significantly reducing the severity of accident damage.

Preventing secondary damage: Traditional rigid barriers are prone to breaking or bending under strong impacts, causing vehicle damage or secondary injuries at the scene. In contrast, flexible barriers can restore their shape after being subjected to force, extending their service life and ensuring operational continuity.

Modular Design for Flexible Installation: Unloading areas typically have limited space and complex layouts. The modular assembly structure of flexible barriers allows for customized installation based on site conditions, without affecting loading/unloading efficiency.

Typical Configuration Schemes for Flexible Guardrails at Unloading Points

Based on the risk level of the unloading area and the type of operations conducted, flexible guardrails can be configured into the following categories:

Single-row collision-proof guardrails: Suitable for small-scale loading and unloading platforms, used to demarcate通道 boundaries and provide light vehicle cushioning.

Double-row collision barriers: Widely used in large logistics loading platforms, effectively preventing forklifts from drifting and colliding with the edge of the loading platform.

Barrier + post combination protection: In loading docks with frequent truck traffic, flexible posts and barriers can be integrated into a single structure to form a planar collision barrier.

Barrier + wheel stopper combination use: Enhances vehicle positioning accuracy to prevent collisions caused by parking drift.

Application Case: Performance of SEPPES Flexible Guardrails in a Logistics and Warehousing Project in Jiangsu Province

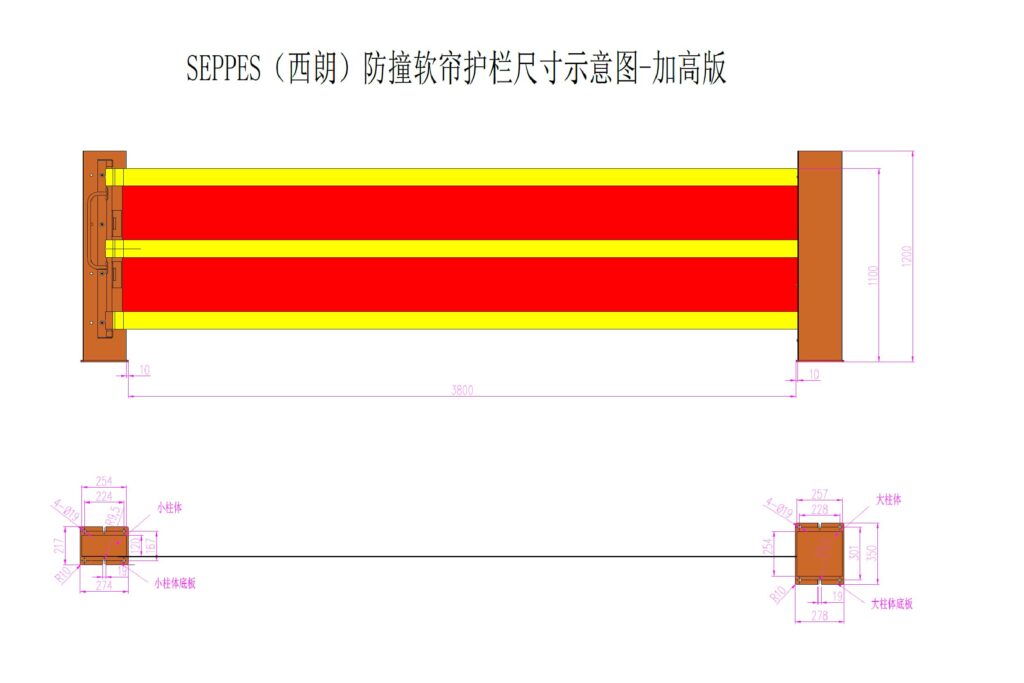

At the logistics park of a large third-party logistics company in Jiangsu Province, over 100 trucks enter and exit the loading dock daily, imposing stringent requirements for high-strength and sustainable use of guardrails. The project team ultimately selected the flexible collision-resistant guardrail system from SEPPES Industrial Doors. Featuring a three-section guardrail design combined with energy-absorbing connectors and ground buffer seats. After six months of use, there have been no instances of guardrail breakage or deformation, and the client has expressed high satisfaction with its performance.

Flexible guardrails are not only about “safety”—they also offer cost and operational efficiency benefits.

Reduced maintenance costs: Traditional steel guardrails need to be replaced entirely when damaged, while flexible structures only require replacement of individual damaged modules, resulting in lower costs.

Improved operational efficiency: Flexible installation does not interfere with forklift access or cargo loading and unloading.

Aesthetic appeal and management compatibility: Available in a variety of colors. They can be coordinated with area markings and signage systems to enhance overall visual management standards.

Conclusion

Selecting appropriate safety protection products for the unloading area is a critical component of safety management for every factory and logistics park. Compared to traditional protective structures. Flexible barriers not only offer superior impact resistance and recovery capabilities but also adapt to complex and dynamic unloading environments, truly achieving the triple protection of “protecting people, protecting equipment, and protecting operations.”

Selecting an efficient and reliable flexible barrier system establishes the first line of defense for loading dock safety. SEPPES Industrial Doors offers a one-stop solution, from site surveys and design to delivery and installation.