As a common access solution in modern industrial, warehousing, and logistics facilities, the way a sectional door opens has a direct impact on operational efficiency, safety, and maintenance costs. In this article, we will focus on the core theme of “sectional door opening method” to help you understand the best choice in different scenarios.

What is a sectional door? Why is the way it opens important?

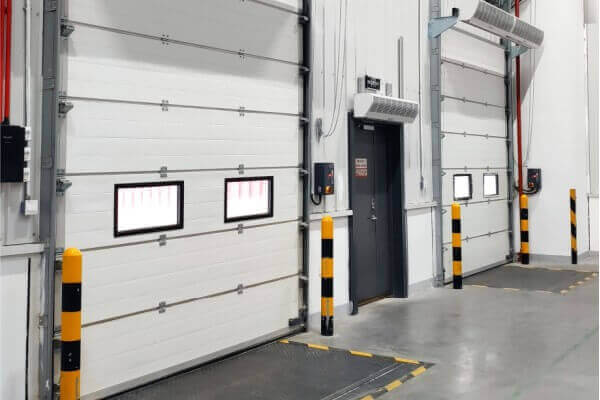

Sectional, door, also known as industrial sectional doors, is usually used in large warehouses, logistics parks, factory workshops, and other places. The door body rises along the track to the ceiling below, occupies little space, good heat preservation, and is widely popular.

The “sectional door opening methods” mainly refer to the drive form and opening structure design of the door body, which affects:

Convenience of operation (manual vs. electric)

Adaptation of use frequency (high-frequency vs. ordinary)

Site compatibility (vertical lift vs standard lift vs high lift)

Improper selection will not only affect the passage efficiency but also may cause wear and tear of equipment and even safety hazards.

Three common ways to open a sectional door

Electric opening mode

Suitable for daily frequent opening and closing of industrial sites, through the motor and control system operation, support for remote control, buttons, radar, and other triggering methods. Advantages include:

Convenient operation, saving labor;

Support linkage control system (such as access control, fire fighting, etc.);

Slow start and stop can be realized to protect the door structure.

Applicable scenes: cold chain logistics, automated three-dimensional warehouse, high-frequency channel.

Manual opening method

Commonly used in areas with low turn-on frequency, limited budgets, or where power access is not available. Pros:

Low cost and simple maintenance;

Reliable structure, suitable for emergency use;

No need for power supply, can be used even if there is a power failure.

Applicable scenarios: simple workshop, remote warehouse, alternate entrances and exits.

Automatic induction opening method

Through radar, geomagnetic, infrared, and other sensing devices, automatically identify people or vehicles approaching to realize automatic opening. It is an important part of intelligent industrial doors.

Enhance the passage efficiency without manual intervention;

Reduce energy loss and improve sealing;

Support intelligent passage of AGV, forklift and other equipment.

Applicable scenes: intelligent warehousing, automated production workshop, clean area.

How to choose a sectional door opening based on the scenario

Consider the frequency of use

For high-frequency scenarios (e.g. logistics centers), electric or automatic induction opening is recommended, while for low-frequency scenarios, manual opening can be selected.

Evaluate the size of the door opening and building structure.

If the building height is sufficient, vertical lifting can be chosen; space-constrained areas are suitable for high or standard lifting tracks.

Confirm functional requirements

Do you need linkage control, anti-pinch protection, low noise operation?

Conclusion: Choose the right sectional door opening methods, for efficient acceleration

Whether it is an electric sectional door, manual sectional door, or intelligent inductive industrial door, the right opening method can greatly improve the operational efficiency and safety level of the industrial site. Before selection, it is recommended to communicate with experienced industrial door manufacturers to make the best decision based on the use of the scene, budget, frequency, and other comprehensive factors.