Get a Quote

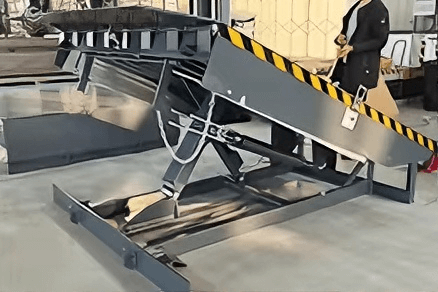

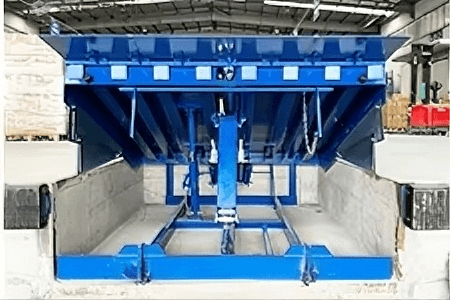

SEPPES Mechanical Dock Leveler – Safe, Stable, Efficient Loading

Heavy-duty platform designed for fast and safe truck loading across all warehouse types.

Product Overview

The SEPPES mechanical dock leveler is a dependable and economical option for your loading dock functions. Built for functionality and durability, it eliminates the need for electrical and hydraulic configurations, providing a safe bridge between your dock and delivery trucks.

The leveler’s ease of use enables your employees to operate the leveler more quickly, increasing safety and efficiency of the loading and unloading process. The materials used in construction warrant long life and low-maintenance intervals. For facilities that see a moderate amount of traffic, this product is clearly a solid purchase. For reliable operation, the mechanical dock leveler SEPPES is the logical choice.

Contact us and learn more about our products !

Mechanical Dock Leveler Key Features

- Easy manual pull-chain operation—no power needed

- Durable steel construction for long-term use

- Cost-effective with low maintenance requirements

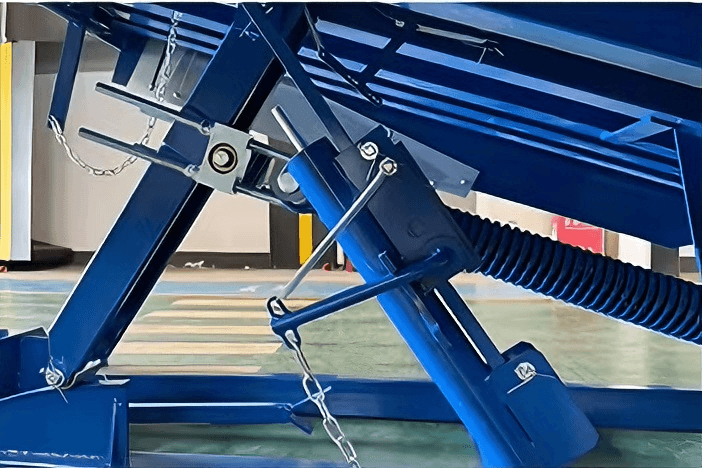

- Built-in safety legs and lock struts

- Anti-slip deck surface for added safety

- Accommodates trailer movement during loading

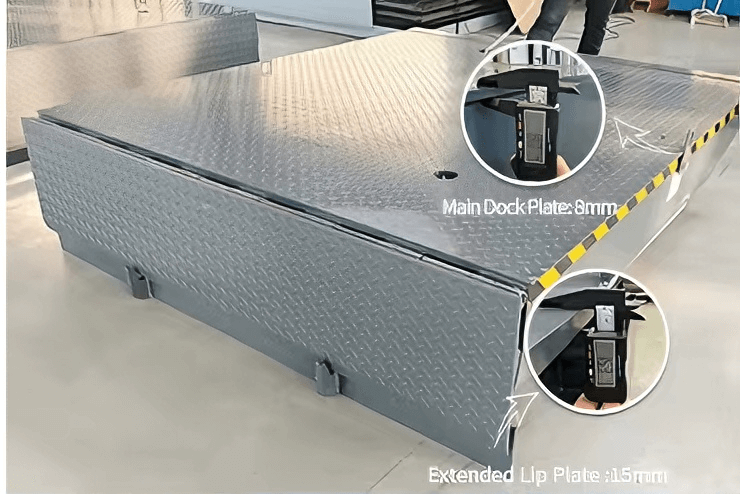

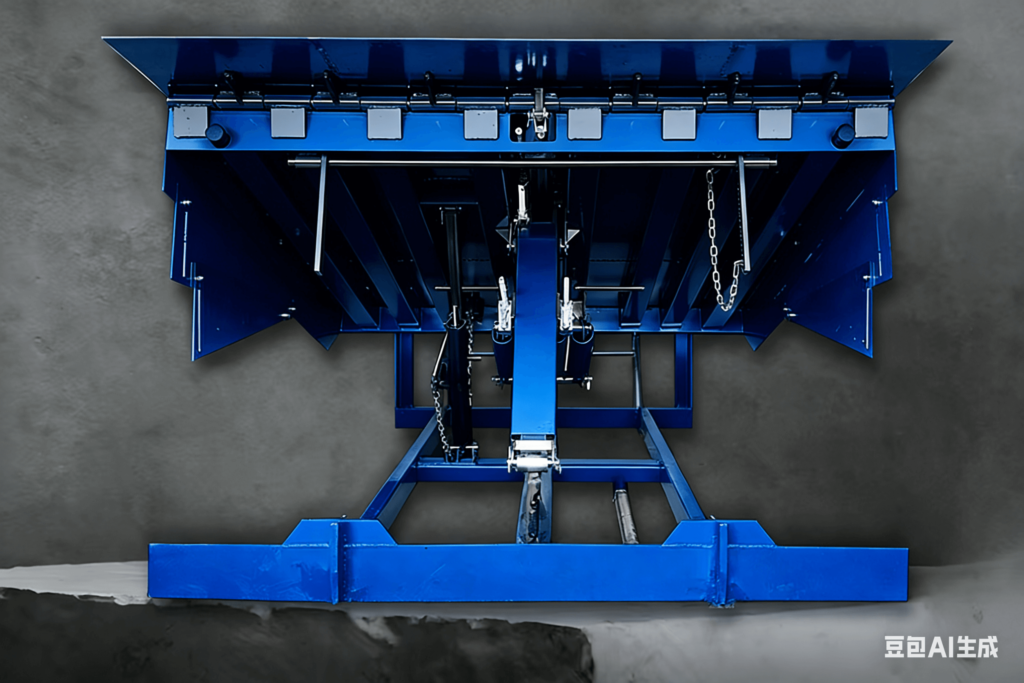

Detail Display Of SEPPES Mechanical Dock Leveler

Manual Operation

No electric power is required for an easy pull-chain system for rapid and straightforward operation.

Stable Structure

Easy to clean, smooth loading, safety plate, anti-fall valve, stable supports, lockable and impact-resistant.

Balancing System

Spring balance for easy manual use, durable steel, nationwide service and 24/7 support.

Low Maintenance

±300 mm range, 8T/10T load, compact design, simple checks only.

Mechanical Dock Leveler Structure

Durable Construction: High-tensile steel which provides long-lasting strength against wear and tear.

Reinforced Support: Heavy duty beams which structural stability and will not bend with heavy-weight load.

Anti-slip Platform: Workers and equipment have safe ground traction.

Reliable Performance: Withstands truck use all the time and performs dock duty with ease.

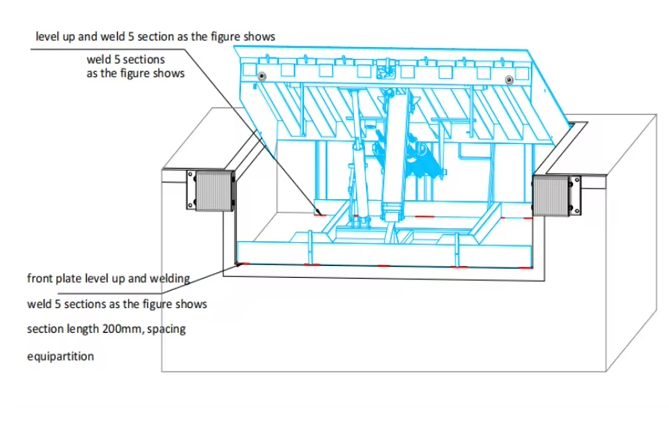

Installation Steps

Site Preparation

Ready the pit by cleaning and verifying that it is square and level.

Positioning The Leveler

Using the appropriate equipment, position the leveler over the pit and lower it into place, double-checking that everything is aligned correctly.

Welding and Anchoring

Completing the frame, weld it to the pit steel and insert all anchors. Do not use the leveler until the welds are cooled.

**Bumper Installation**

Position the dock bumpers onto the foundation wall; confirm that they are completely secured.

Final Adjustments and Testing

Pull-chain and system adjustments can be made to complete the installation. Once completed, operate the leveler through a full cycle to confirm that it is functioning fully.

Our Dock Leveler Project Cases

Dubai -Plastic Manufacturing Company

The client is a big player in pharmaceutical logistics in the area. They use our dock leveler to integrate their logistics process with their production line, allowing the customer to efficiently deliver plastic items to the production line, streamline the process, and fulfill market demands.

Indonesia -Material Handling Warehouse

The customer runs one of the biggest retail businesses in Indonesia, with several distribution centers across the country. They picked our dock leveler for the optimal distribution of their products and enhanced customer experience. This customer has improved their business logistics, lowered their costs, and gained faster service.

America -International Logistics Company

Some clients are the worldwide distribution and logistic centers that move thousands of tons of cargo every day. Dock levelers help ensure quick transshipment and distribution of goods by providing efficient and safe loading processes. Our dock levelers are conveniently height adjustable to different trucks and cargo sizes to better boost productivity.

Common Types of Dock Levelers

Learn about some of the most common dock levelers and note unusual designs offered by some manufacturers.

Hydraulic Dock Leveler

Mechanical dock levelers are built for easy usability and durability. They are a sound choice for facilities with moderate traffic and basic operational needs. The levelers work using a spring system and a manual pull chain. Using no electricity helps reduce operational costs. Based on the design, they require very little maintenance and are trusted easy performers. They are the best choice for facilities that require dock levelers, but also have lower traffic or are on a tight budget.

Edge of Dock Levelers

For loading areas not too big, edge of dock levelers work perfectly. Edge of dock levelers work well for facilities with smaller budgets and space, and their height adjustment range is great. Compared to dock boards, edge of dock levelers provide a safer and more ergonomic footing and are much better at eliminating fall-related injuries. Edge of dock levelers are intended for standard loading dock heights. While a lot of businesses have edge of dock levelers, their limitations and tolerances are still huge, and their prices are still affordable, and with great safety features, edge of dock levelers are still a great option for businesses.

Vertical Dock Leveler

Vertical dock levelers feature a unique configuration and design allowing for an even more robust and effective seal when stored upright and under the dock. Although these levelers are hydraulic and vertical when not in use, they will stay vertically aligned. Because of these vertical design features, the levelers seal the door opening during the raised position. This prevents the loss of conditioned air and keeps the warehouse environment efficient. Vertical dock levelers help logistics companies keep a tight, controlled internal environment and reduce energy loss. This is more of a concern for companies that prioritize cleanliness and energy efficiency.

Loading Dock Scissor Leveler

Scissor lift levelers at loading docks are dependable for the varied heights of trucks. The scissor lift mechanism provides stable elevation adjustments. The levelers are hydraulic, allowing easy and safe operation, ideal for busy working conditions. Levelers provide efficient loading and unloading, even at varying heights.

Telescopic Dock Leveler

Vertical dock levelers feature a unique configuration and design allowing for an even more robust and effective seal when stored upright and under the dock. Although these levelers are hydraulic and vertical when not in use, they will stay vertically aligned. Because of these vertical design features, the levelers seal the door opening during the raised position. This prevents the loss of conditioned air and keeps the warehouse environment efficient. Vertical dock levelers help logistics companies keep a tight, controlled internal environment and reduce energy loss. This is more of a concern for companies that prioritize cleanliness and energy efficiency.

Resources on Hydraulic Dock Leveler

Working with 4200+ global clients

We have authentic and authoritative certificates

Why is the product quality of many brands not up to standard? Because none of what they show you is a real certificate. Our certificates are authentic. You can request a report from us.

Frequently Asked Questions About SEPPES Dock Leveler

How do you operate a mechanical dock leveler?

There’s a very straightforward method to use, and it doesn’t need any power. Pulling a specially designed cord activates a gear-equipped spring and raises the dock. Once at the desired height, the truck ramp folds out, and the worker can move the the dock to close it and ensure that the ramp is securely stowed.

What are the primary safety features?

All SEPPES mechanical dock levelers have curtained dock systems shields, designed specifically to close the sides of the dock once the truck is in position, so that no gaps remain and the space is fully sealed.

What kind of maintenance does a mechanical leveler require?

These levelers, along with a few other dock equiment, of the many other dock systems, have no unnecessary elecntronics and can be completly operated with mechanical control, which of dock levelers make them very intuitive and easy to use.

Can anyone install a mechanical dock leveler?

All installation must be performed by certified technicians with a complete understanding of the dock levelers system and equipment. Their qualified installation is extremely nessacary gowdy speifically to welding, anchoring and the correct otder of system adjustments.

How is a mechanical dock leveler cost-effective?

This model is cheaper to own overall than hydraulic models. To begin with, the purchase price is elss. It also consumes no electrical power, so energy costs are also minimized. Its design is also more simple with fewer moving parts, so long-term maintenance and repair costs are also reduced.

How durable is the SEPPES mechanical dock leveler?

It is built to last and constructed with high tensile steel and reinforced beams. It is designed to endure daily heavy forklift activities and heavy loads, thus, ensuring long-term destination, integrity and performance.

Is this leveler compatible with different truck heights?

Sure, the service range is designed to accommodate most standard truck and trailer height. It also ‘floats’ enabling the deck to move with the trailer suspension in place during loading/unloading.

What is the typical load capacity?

SEPPES mechanical dock levelers range most dynamic load capacities, varying from 25,000 to 50,000, to match different operational provision. You should choose the one that best fits the maximum weight of the forklift and loads to avoid problems with operational continuity.