Get a Quote

SEPPES Vertical Dock Leveler – Safe, Stable, Efficient Loading

Heavy-duty platform designed for fast and safe truck loading across all warehouse types.

Product Overview

The SEPPES mechanical dock leveler is a dependable and economical option for your loading dock functions. Built for functionality and durability, it eliminates the need for electrical and hydraulic configurations, providing a safe bridge between your dock and delivery trucks.

The leveler’s ease of use enables your employees to operate the leveler more quickly, increasing safety and efficiency of the loading and unloading process. The materials used in construction warrant long life and low-maintenance intervals. For facilities that see a moderate amount of traffic, this product is clearly a solid purchase. For reliable operation, the mechanical dock leveler SEPPES is the logical choice.

Contact us and learn more about our products !

Vertical Dock Leveler Key Features

Vertical Storage Design: Keeps the dock area clean and secure, ideal for temperature-controlled and hygienic environments.

Energy Efficiency: Minimizes energy loss with a tight seal when not in use, reducing operational costs.

Durable Construction: Built with high-quality materials to withstand heavy-duty usage and ensure long-term reliability.

Enhanced Safety Features: Includes advanced safety mechanisms to protect workers and equipment during operation.

Easy Operation: User-friendly controls and smooth functionality streamline loading and unloading processes.

Customizable Options: Tailored configurations to meet specific facility requirements and operational needs.

Vertical Dock Leveler Date Sheet

| Parameter | Specification |

|---|---|

| Type | Hydraulic Vertical Dock Leveler |

| Structure | Heavy-duty reinforced frame |

| Rated Capacity | 8–20 tons (customizable) |

| Platform Size | Standard 2000×2500 mm (customizable) |

| Platform Material | High-strength anti-slip steel plate |

| Lip Length | 400 mm (customizable) |

| Working Range | Pit-mounted with vertical storage design |

| Power Unit | Hydraulic power pack with single or double cylinder |

| Material | High-strength steel, anti-slip surface |

| Voltage | 380V / 220V (customizable) |

| Control System | Push-button control |

| Storage Position | Fully vertical, door closes to the floor |

| Hydraulic System | Smooth lifting, low-maintenance design |

| Finish | Powder coated, color customizable |

| Operation | Smooth hydraulic lifting and lowering |

| Options | Lip size, platform size, voltage, color, and logo all customizable |

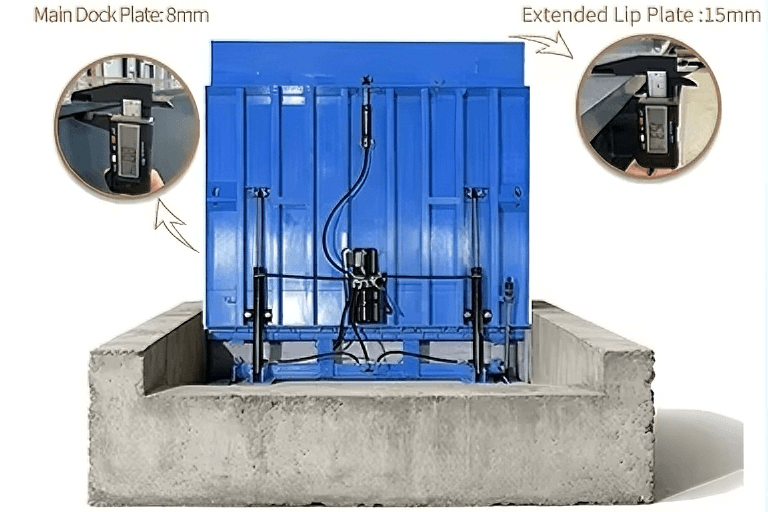

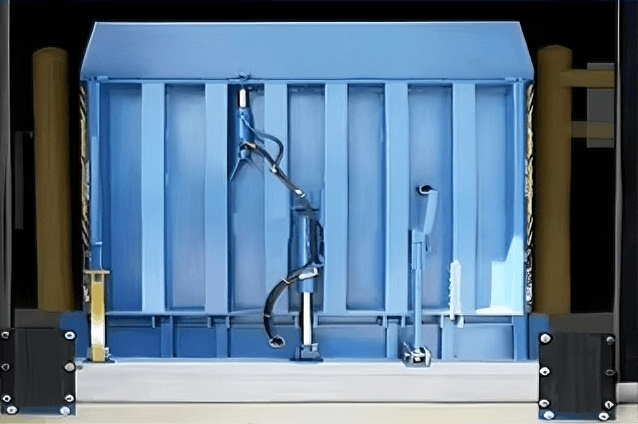

Detail Display Of SEPPES Vertical Dock Leveler

STABLE STRUCTURE

CC Smooth Transition: Special Hinge & Deck Design Ensure Smooth Loading & Unloading

CC Accident Prevention: Unused Extended Plate – Stand Up, Stop Forklifts From Off Platform

CC Prevent Fall: Safety Valve Halts Quick Drop (3 Inches)

CC Maint Safety: Support Bars (extension) – Stable, Lockable, Anti-impact

DRIVING SYSTEM

CC Hydraulic Power Unit: 380V/1.1KW

CC Hydraulic Speed Limit: ≤75mm/s; Auto-stops Leveler & Loads

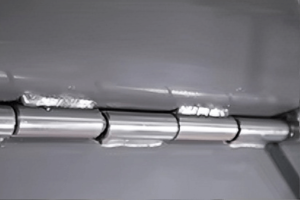

CC Double-wire Mesh Hydraulic Oil Pipe (48mpa Max Load)

CC Hydraulic Oil For Low-temperature & High-radiation Areas

DOCK LEVELER DATA

CC Working Range: ±300mm

CC Load: Dynamic 8 Ton & Statics 10 Ton

CC One-Key Control Panel / Option:Emergency Button

CC Customization:Size / Color / Galvanizing Process

Vertical Dock Leveler Other details

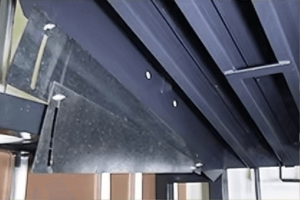

1.I-BEAM

Core Structural Components

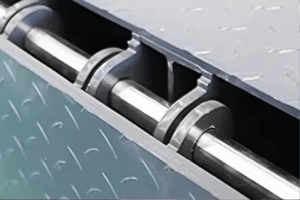

2.LIP HINGE WELDING

Dock leveler lip plate adjusts loading unloading height

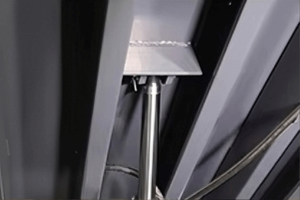

3.HYDRAULIC BAR SUPPORTING

Through-type safety support secures adjustment plate

4.HEAD HYDRAULIC SPARE PART

System Maintenance & Replacement

5.FOOT PROTECTION SIDES

Foot Protection Prevents Safety Hazards.

6.OPENING HINGE

Dust-proof Advantage

Vertical dock leveler Installation Steps

- Site Preparation: Ensure the dock pit is clean, level, and meets the required dimensions for the leveler. Verify that all electrical and hydraulic connections are ready.

- Positioning the Leveler: Carefully place the dock leveler into the pit using appropriate lifting equipment, ensuring it aligns with the dock frame.

- Securing the Leveler: Anchor the leveler to the dock frame using bolts or welding, as specified in the installation manual.

- Hydraulic and Electrical Connections: Connect the hydraulic system and electrical components to the power source, following the manufacturer’s guidelines.

- Testing and Calibration: Test the leveler’s functionality, including raising, lowering, and safety features. Make necessary adjustments for smooth operation.

- Final Inspection: Conduct a thorough inspection to ensure all

Our Dock Leveler Project Cases

Dubai -Plastic Manufacturing Company

The client is a big player in pharmaceutical logistics in the area. They use our dock leveler to integrate their logistics process with their production line, allowing the customer to efficiently deliver plastic items to the production line, streamline the process, and fulfill market demands.

Indonesia -Material Handling Warehouse

The customer runs one of the biggest retail businesses in Indonesia, with several distribution centers across the country. They picked our dock leveler for the optimal distribution of their products and enhanced customer experience. This customer has improved their business logistics, lowered their costs, and gained faster service.

America -International Logistics Company

Some clients are the worldwide distribution and logistic centers that move thousands of tons of cargo every day. Dock levelers help ensure quick transshipment and distribution of goods by providing efficient and safe loading processes. Our dock levelers are conveniently height adjustable to different trucks and cargo sizes to better boost productivity.

Common Types of Dock Levelers

Learn about some of the most common dock levelers and note unusual designs offered by some manufacturers.

Hydraulic Dock Leveler

SEPPES designs and builds top tier dock levelers that improve the efficiency and safety of the process of handling cargo. Our dock lifts are built to last and are designed to serve various industrial environments like warehouses, logistic centers, distribution centers, and ports.

Interaction between the control system, electric hydraulic power unit, the adjusting plate, and the tongue plate of the Hydrolic Dock Leveler work harmoniously to close the height gap between the bottoms of the d is looseoughedroggy plates and the transport vehicles, creating a seamless bridging of the vehicle to the platform that facilitates quick and easy loading and unloading.

Edge of Dock Levelers

For loading areas not too big, edge of dock levelers work perfectly. Edge of dock levelers work well for facilities with smaller budgets and space, and their height adjustment range is great. Compared to dock boards, edge of dock levelers provide a safer and more ergonomic footing and are much better at eliminating fall-related injuries. Edge of dock levelers are intended for standard loading dock heights. While a lot of businesses have edge of dock levelers, their limitations and tolerances are still huge, and their prices are still affordable, and with great safety features, edge of dock levelers are still a great option for businesses.

Mechanical Dock Leveler

Mechanical dock levelers are built for easy usability and durability. They are a sound choice for facilities with moderate traffic and basic operational needs. The levelers work using a spring system and a manual pull chain. Using no electricity helps reduce operational costs. Based on the design, they require very little maintenance and are trusted easy performers. They are the best choice for facilities that require dock levelers, but also have lower traffic or are on a tight budget.

Loading Dock Scissor Leveler

Scissor lift levelers at loading docks are dependable for the varied heights of trucks. The scissor lift mechanism provides stable elevation adjustments. The levelers are hydraulic, allowing easy and safe operation, ideal for busy working conditions. Levelers provide efficient loading and unloading, even at varying heights.

Telescopic Dock Leveler

Vertical dock levelers feature a unique configuration and design allowing for an even more robust and effective seal when stored upright and under the dock. Although these levelers are hydraulic and vertical when not in use, they will stay vertically aligned. Because of these vertical design features, the levelers seal the door opening during the raised position. This prevents the loss of conditioned air and keeps the warehouse environment efficient. Vertical dock levelers help logistics companies keep a tight, controlled internal environment and reduce energy loss. This is more of a concern for companies that prioritize cleanliness and energy efficiency.

Resources on Hydraulic Dock Leveler

Working with 4200+ global clients

We have authentic and authoritative certificates

Why is the product quality of many brands not up to standard? Because none of what they show you is a real certificate. Our certificates are authentic. You can request a report from us.

Frequently Asked Questions About SEPPES Dock Leveler

What is a Vertical Dock Leveler?

A vertically storing dock leveler keeps the dock area clean while also securing the area to store the leveler in an energy-efficient way.

What are the benefits of vertical storage?

Vertical levelers also support cleanliness, energy retention, temperature regulation, and overall better facility temperature control.

What weight capacities are available?

Vertical Dock Levelers come in many different weight capacities to accommodate even the most light to heavy duty operations.

Are Vertical Dock Levelers customizable?

Yes, they can be customized to accommodate particular dock layouts and operational requirements.

What safety features are included?

For safety features, anti-slip surfaces, locking systems, and protective barriers are common.

How is a Vertical Dock Leveler operated?

Most models come installed with hydraulics and electric mechanisms for controlling the dock leveler for a smooth and efficient operation. See below for how to best control the dock leveler.

What maintenance is required?

For best operational performance, document your observations on moving parts for regular inspections, lubrication, and hydraulic and electrical systems check.

Is professional installation necessary?

Yes, professional installation is the best way to go to cover your bases on proper setup, safety, and functionality.