Get a Quote

SEPPES Truck Restraint System – Safe, Stable, Efficient Loading

Heavy-duty platform designed for fast and safe truck loading across all warehouse types.

Product Overview

The SEPPES Truck Restraint System is a state-of-the-art safety system that protects facility employees and equipment while loading or unloading cargo and prevents unauthorized truck movement during the process. The system is user-friendly and dependable that utilizes multiple state-of-the-art locking systems alongside visual signaling that optimizes efficiency and communication within the system. The SEPPES Truck Restraint System is the most effective choice for precavidng the serious safety and operational hazards of dock settings. It is perfect for any warehouse, distribution center, or other industrial site.

Contact us and learn more about our products !

Truck Restraint System Key Features

Advanced Locking System: Locks trucks in place so that they can’t move by accident.

Visual and Audible Alerts: Notifies operators with lights and sound.

Durable Construction: Designed to handle heavy industrial use and tough conditions.

Easy Integration: Easy to install and fits with most dock layouts.

Safety Compliance: Complies with regulations to keep people safe in the workplace and mitigate hazards.

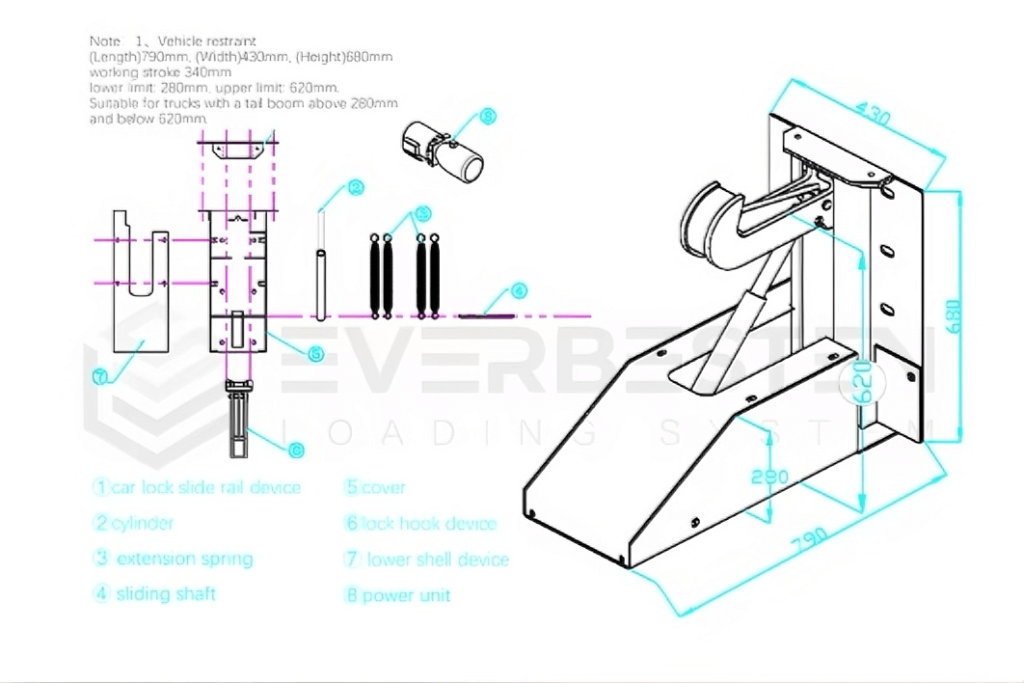

Truck Restraint Data Sheet

| Product Type | Vehicle Restraint / Truck Restraint |

|---|---|

| Types Available | Hydraulic / Electric / Sensor-type |

| Locking Method | ICC bar locking / Wheel chock locking |

| Locking Range | Custom ICC bar height (e.g., 300–600 mm) |

| Structure Material | High-strength, powder-coated steel |

| Drive System | Hydraulic cylinder / Electric motor |

| Control System | Push-button panel / PLC interlock / Traffic lights |

| Safety Features | Overload protection, door interlock, sensor detection |

| Holding Force | Customizable (e.g., 15–35 kN) |

| Operating Temperature | -30°C to +50°C |

| Power Supply | 110V / 220V / 380V optional |

| Installation Type | Surface-mounted / Bolt-on / Embedded |

| Weather Protection | Outdoor-rated housing and components |

| Optional Add-ons | LED guide lights, long arm, stainless steel version |

| Customization | Locking height, arm length, labels, panel layout |

| Application | Cold chain / Food / Logistics / Warehousing |

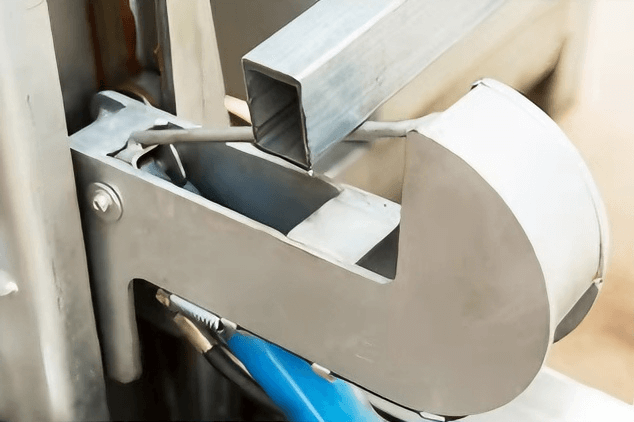

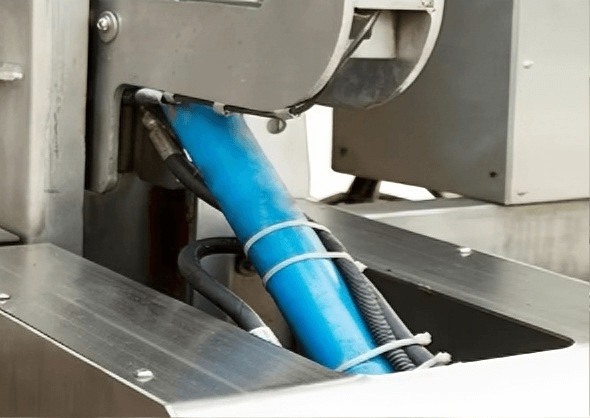

Detail Display Of SEPPES Truck Restraint System

AUTOMATIC SENSOR

Automatic Locking & Unlocking / High-Precision Sensors

Wireless Control / Durable and Weather-Resistant

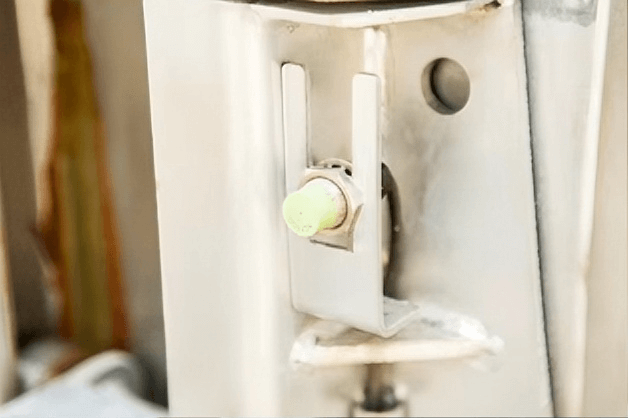

MECHANICAL LIMIT SWITCH

Designed to Protect Your Machinery from Overextension and Damage

AUTOMATIC LOCKING/UNLOCKING

High Force Output / Precise Control / Low Maintenance

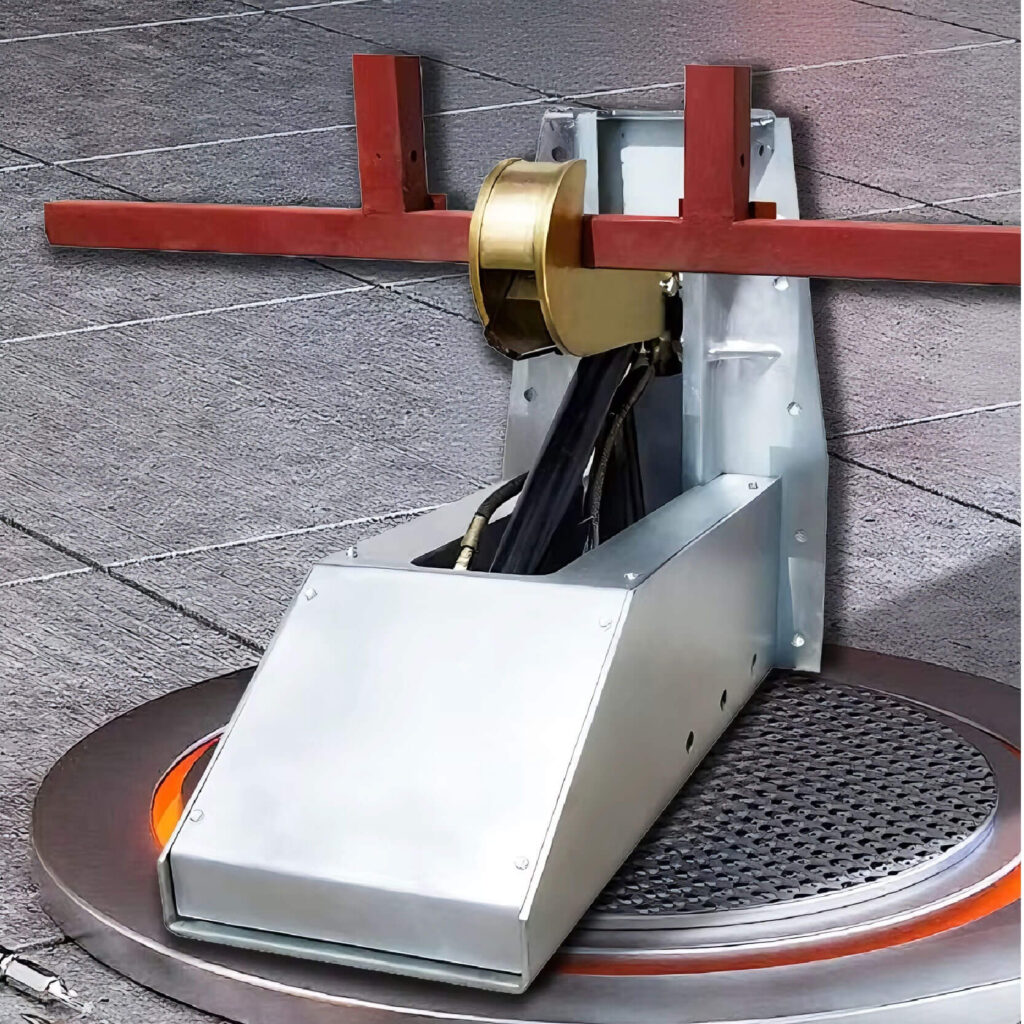

Truck Restraint System Structure

Restraint Arm/Hook: A strong mechanism that secures to the truck’s rear eGate to stop movement.

Mounting Base: A strong base that attaches the system to the dock for security.

Control Panel: A user-friendly system allowing operators to activate, check, and control the system.

Signal Lights: Built-in lights show the condition of the system to dock workers and drivers.

Weatherproof Housing: Ensures that the system’s internal parts are well protected from the elements for maximum system life.

Truck Restraint System Installation Steps

Restraint Arm/Hook: A strong mechanism that secures to the truck’s rear eGate to stop movement.

Mounting Base: A strong base that attaches the system to the dock for security.

Control Panel: A user-friendly system allowing operators to activate, check, and control the system.

Signal Lights: Built-in lights show the condition of the system to dock workers and drivers.

Weatherproof Housing: Ensures that the system’s internal parts are well protected from the elements for maximum system life.

Our Truck Restraint Project Cases

Saudi Arabia – Food Packaging Manufacturer

One of our clients is a food packaging supplier. They provide stores and restaurants with plastic food containers. We installed a Truck Restraint System that makes sure trucks are securely fastened to the dock when unloading. This minimizes the chance of a moving vehicle and offers a safer way to handle materials.

Vietnam - Electronics Plastic Components Factory

This factory manufactures plastic parts that are used in the electronics industry. They have a lot of shipments that come in and go out. Our Truck Restraint product ensures that all trucks are secured in place when unloading to improve safety at the dock and ensure a steady flow of logistics.

Mexico – Chemical Logistics Distribution Center

Our customer has a chemical logistics distribution center that stores plastic drums and containers. With our Truck Restraint System, vehicles are secured at the dock to eliminate the possibility of a moving vehicle and improve safety and efficiency during the loading process.

Common Types of Dock Levelers

Learn about some of the most common dock levelers and note unusual designs offered by some manufacturers.

Hydraulic Dock Leveler

SEPPES designs and builds top tier dock levelers that improve the efficiency and safety of the process of handling cargo. Our dock lifts are built to last and are designed to serve various industrial environments like warehouses, logistic centers, distribution centers, and ports.

Interaction between the control system, electric hydraulic power unit, the adjusting plate, and the tongue plate of the Hydrolic Dock Leveler work harmoniously to close the height gap between the bottoms of the d is looseoughedroggy plates and the transport vehicles, creating a seamless bridging of the vehicle to the platform that facilitates quick and easy loading and unloading.

Vertial dock leveler

Vertical dock levelers feature a unique configuration and design allowing for an even more robust and effective seal when stored upright and under the dock. Although these levelers are hydraulic and vertical when not in use, they will stay vertically aligned. Because of these vertical design features, the levelers seal the door opening during the raised position. This prevents the loss of conditioned air and keeps the warehouse environment efficient. Vertical dock levelers help logistics companies keep a tight, controlled internal environment and reduce energy loss. This is more of a concern for companies that prioritize cleanliness and energy efficiency.

Mechanical Dock Leveler

Mechanical dock levelers are built for easy usability and durability. They are a sound choice for facilities with moderate traffic and basic operational needs. The levelers work using a spring system and a manual pull chain. Using no electricity helps reduce operational costs. Based on the design, they require very little maintenance and are trusted easy performers. They are the best choice for facilities that require dock levelers, but also have lower traffic or are on a tight budget.

Loading Dock Scissor Leveler

Scissor lift levelers at loading docks are dependable for the varied heights of trucks. The scissor lift mechanism provides stable elevation adjustments. The levelers are hydraulic, allowing easy and safe operation, ideal for busy working conditions. Levelers provide efficient loading and unloading, even at varying heights.

Telescopic Dock Leveler

Vertical dock levelers feature a unique configuration and design allowing for an even more robust and effective seal when stored upright and under the dock. Although these levelers are hydraulic and vertical when not in use, they will stay vertically aligned. Because of these vertical design features, the levelers seal the door opening during the raised position. This prevents the loss of conditioned air and keeps the warehouse environment efficient. Vertical dock levelers help logistics companies keep a tight, controlled internal environment and reduce energy loss. This is more of a concern for companies that prioritize cleanliness and energy efficiency.

Resources on Hydraulic Dock Leveler

Working with 4200+ global clients

We have authentic and authoritative certificates

Why is the product quality of many brands not up to standard? Because none of what they show you is a real certificate. Our certificates are authentic. You can request a report from us.

Frequently Asked Questions About SEPPES Truck Restraint System

What is the purpose of the SEPPES Truck Restraint System?

It secures trucks during loading and unloading to prevent accidental movement, ensuring safety for workers and cargo.

Is the system compatible with all truck types?

Yes, it is designed to accommodate a wide range of truck sizes and rear impact guard configurations.

How does the system communicate its status?

The system uses LED lights and audible alarms to indicate operational status and safety conditions.

Can it withstand harsh weather conditions?

Absolutely, the system is built with weather-resistant materials for reliable performance in extreme environments.

Is the installation process complex?

No, the system is designed for straightforward installation with clear instructions and minimal downtime.

Does it require regular maintenance?

Routine inspections and basic maintenance are recommended to ensure optimal performance and longevity.

Is the system compliant with safety standards?

Yes, it meets industry safety regulations and standards for dock equipment.

Can it integrate with existing dock systems?

Yes, it can be seamlessly integrated with other dock equipment, such as signal lights and control systems.