Efficient, secure, and well-designed dock doors are the backbone of modern warehouses, driving streamlined operations and safeguarding valuable goods. Whether it’s facilitating seamless shipments, preventing unauthorized access, or minimizing energy loss, dock doors play an indispensable role in the competitive world of logistics. This article will explore how advanced dock door solutions can revolutionize warehouse efficiency, bolster security, and adapt to the evolving demands of supply chain management. Read on to uncover the critical features and strategies that can turn your warehouse dock doors into a pivotal asset for your business success.

What Are Warehouse Dock Doors?

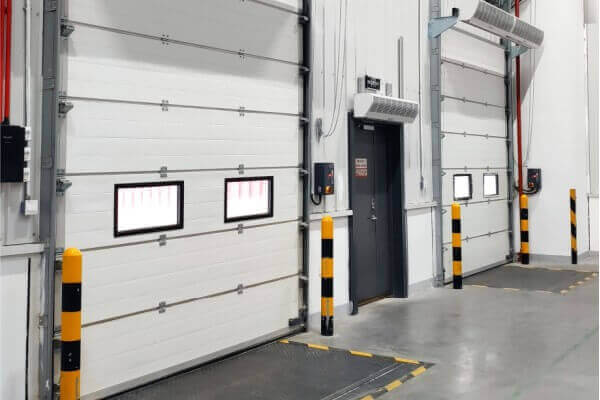

Dock doors are designed for loading and unloading freight from trucks, serving as the primary entry and exit points for warehouse shipments. Dock doors are a crucial part of the warehouse’s interface with the supply chain, enabling the flow of products in and out while protecting the warehouse interior from the external environment. Warehouse docks can have different styles of doors, like sectional doors, roll-up doors, and high-speed doors but each meets its own operational requirement. Correct and timely maintenance of all types of docks maximizes the potential of the warehouse.

Definition and Core Functionality

Warehouse dock doors are specialized entrances designed to facilitate the smooth transfer of goods between vehicles and the warehouse facility. Their core functionality revolves around providing a secure, efficient, and weather-resistant environment for loading and unloading operations. Dock doors act as a vital connection point in the supply chain, ensuring that materials move seamlessly while protecting them from external environmental factors such as rain, wind, or extreme temperatures.

Modern warehouse dock doors are increasingly integrated with advanced technology to enhance efficiency and safety. For instance, high-speed doors with automated sensors maximize operational speed while minimizing energy loss. Additionally, dock bumpers, seals, and levelers work alongside the doors to create a tight seal, ensuring thermal control and reducing potential damage during docking activities. The careful selection of warehouse dock doors, factoring in operational needs, material composition, and technological capabilities, is critical to optimizing warehouse operations and maintaining overall supply chain efficiency.

Role in Warehouse Operations and Logistics

Warehouse dock doors are integral components in efficient supply chain operations as they serve as the primary interface between the warehouse and vehicles. These doors are strategically designed to facilitate the rapid transfer of goods while safeguarding products against environmental factors such as adverse weather conditions and temperature fluctuations. Technological advancements like automated dock doors and smart systems now allow for seamless integration with warehouse management systems (WMS), streamlining processes and reducing human error. Features such as RFID-enabled tracking, energy-efficient insulation materials, and high-speed opening mechanisms contribute to enhanced operational efficiency. By reducing delay in goods movement and improving thermal control, modern dock doors significantly impact the overall logistics workflow, raising the standard of safety, productivity, and sustainability within warehousing operations.

Key Features and Benefits of Warehouse Dock Doors

Secure Access and Protection for Goods

Warehouse dock doors protect goods from risks while loading and unloading, or storing them. Here are five essential security and access protection features.

Advanced Locking Mechanisms

High-performance locking systems prevent unauthorized access and keep access. This leads to lower risks of theft and tampering, especially when using high-security rolling dock doors.

Weather-Resistant Seals

Durable seals keep out dust, moisture, and extreme temperatures. This ensures goods stay protected under extreme and varying outside environmental conditions.

Impact-Resistant Materials

Steel or reinforced heavy-duty aluminum withstands accidental smashes from forklifts and other machinery.

Automated Access Controls

Use of radio frequency identification technology (RFID) or smart sensors for manual access control improves access and security monitoring.

Fire-Resistant Properties

Dock doors designed to be fireproof help meet fire safety regulations, protecting stored goods and people from fire risks. This is more protective and better for personnel safety during emergencies.

Facilitating Efficient Loading and Unloading

It is vital to operational efficiency across the entire supply chain to have optimal systems for the quick loading and unloading of warehouse dock doors to minimize downtime. What follows are five characteristics that optimize the time and resources needed for loading and unloading.

Hydraulic dock levelers

These can adjust to the differing heights of every variety of trailer, and create a bridge between the dock and the trailer. Research shows that when compared to manual systems, which are available, this technology can save loading time by as much as thirty percent.

Sealed dock shelters

These dock shelters create a tight seal between the dock and the truck, protecting the potentially weather-damaged goods from rain, wind, and extreme operational temperature changes, thereby decreasing product damage. This operational efficiency advantage can be significant.

High-speed roll-up doors

These doors minimize wait times as they can open and close quickly in order to facilitate a fully flowing goods operational system. A twenty percent improvement in the warehouse throughput has been reported by those who have incorporated high-speed roll-up doors in their loading bays.

LED Dock Lighting systems

These are designed to improve safety and accuracy while loading and unloading by enhancing nighttime visibility and thereby improving efficient operational safety.

Automated vehicle restraints

Automated vehicle restraints have been shown to improve safety for dock workers by eliminating the potential of trailer movement during the loading and unloading process. A forty percent reduction in injuries related to the dock has been reported when automated restraints are incorporated, and this is corroborated by numerous studies.

Weather Resistance and Environmental Control

Keeping a warehouse operationally effective means being able to control the weather and the environment, and the first line of defense, as far as protecting the premises and the people are concerned, is the warehouse dock doors. Below are some of the key features that help to control the weather and environment as they pertain to the dock doors.

Insulated Panels

Insulated dock doors allow the warehouse to keep the internal temperature at the desired setting, which keeps the climate-dependent products at the required temperature. Studies show that with insulated doors, a warehouse can lose up to 30% less energy,

Sealed Dock Levelers

By adding weather seals, dock levelers can prevent drafts, help with stopping water, and keep debris from coming in, which improves energy efficiency and creates a better working environment.

Overhead Canopies

Canopies provide cover from the rain, snow, and sun, which gives a safe and comfortable area for people to load and unload the docking area in any weather.

Heavy-Duty Gaskets

Gaskets that are cemented to the dock door edges can keep out excess moisture, dust, and bugs, which keeps a clean environment and protects the products from getting contaminated.

High-Speed Roll-Up Doors

These doors open and close very quickly, and because of that, the amount of air that gets exchanged when a door is open is minimized. Because of that, energy is saved, and better environmental control is achieved within the facility.

Safety Features for Personnel and Equipment

Safety Systems Activated by Sensors

Highly developed motion detectors pick up on the presence of people or objects around the dock doors in order to avoid their inadvertent closure. Research shows sensor-activated systems can help decrease workplace injury by as much as 30%.

Engage Manually in Case of Emergency

This entails the ability to open the door manually in the event of a power failure or other emergencies. Thus, absolute access and means of escape in emergencies can be assured. It is also necessary in order to observe safety and control measures in highly populated zones.

Lights for Warning of Dock Doors Closing are crucial for the safety of personnel and the integrity of loading dock equipment.

These dock doors come with LED Lights, which help to signal to employees the movements of the doors or if the doors are in a locked position. Safety reports show these kinds of visible warnings can help in reducing accidents by 25% in highly trafficked areas.

Safety Edge to Prevent Crushing

An anti-crush safety edge is added to the base of the warehouse door, which detects pressure. This safety feature is made to reverse the closure of the door should it come into contact with people or objects, thus preventing accidents while the door is closing.

Non-Slip Surface Safety Materials

The flooring near dock doors is made with specific slip-resistant functionality or treatments to help decrease the chances of slipping or falling, which is known to be extreme in areas of high moisture or spills. This precaution is made particularly for incident reduction, especially in workplaces where good shoe traction is needed.

Types of Warehouse Dock Doors

Sectional Overhead Dock Doors

Sectional overhead dock doors offer unmatched versatility and durability; hence, they are a great profile dock door option for storage warehouses. Sectional overhead dock doors consist of multiple horizontally hinged track doors that slide open vertically. They are made out of insulated, rigid steel panels, aluminum, and or insulated steel sandwich panels that provide efficiency, product durability, weather tightness, and strength throughout a variety of industries.

Incorporation of insulated panels and materials that reduce sound, impact, and are protective of the doors themselves for greater resistance has become a modern feature of sectional overhead dock doors. They can customization dimensions, materials, and finishing to fit the various requirements of different storage warehouses. This feature also allows the addition of automated operation systems for remote operation, increased safety, and smooth operation. Popularity and the factors discussed make sectional overhead dock doors a great example of efficient and reliable modern warehouse components.

Rolling Steel Dock Doors

The Rolling Steel Dock Doors are an important feature for industrial and commercial buildings. They are specifically made for optimum storage, security, and functioning. The Steel Dock Doors are made of interlocking steel slats and are incredibly sturdy. They are made to face and withstand adverse circumstances, with the elements as well as overpowering and harsh outside usage. The slats roll up and provide seamless access to the entrance while also remaining compact by staying stored in a coil above the opening.

Compared to the other form of Steel Dock Doors, these are improved. They come with insulated slats for better temperature control, which decreases the overall cost, are made of steel and protected with a seal for durability, and prevent the loading dock from losing cooled air or getting water inside. Other systems for Steel Dock Doors offer automation improvements for a quick and easy workflow.

The Steel Dock Doors offer a wide variety of shapes, styles, colors, and operating speeds to reflect and fill in the needs for your specific operational needs. The varied industries, from manufacturing to warehousing and logistics, enjoy these doors for the wonderful security, low maintenance, and cost-saving durability. Overall, these dock doors reflect a balance of the most practical and the most modern innovations for industrial complexes.

High-Speed and Insulated Dock Doors

These high-speed insulated dock doors are an impressive piece of technology meant to improve efficiency, security, and energy savings. These doors open and close rapidly, optimizing workflows and reducing downtime. These doors are essential in industries where time is key, like warehousing, manufacturing, and cold storage. The advanced insulation in these doors helps maintain temperature-controlled environments, which is important for preserving goods and saving energy.

High-speed insulated dock doors, built from strong materials and advanced sealing systems, provide remarkable thermal efficiency and endure harsh weather conditions, making them essential for any door company. To increase safety and ensure seamless movement for people and vehicles, modern designs often feature smart automated systems. These doors are designed to accommodate particular operational requirements and include a variety of customization options that improve versatility, such as built-in vision panels, reinforced heavy-duty frames, and seamless integration with automated access control systems. These doors are an important amalgamation of modern technology and useful design and are a great necessity for companies looking to enhance their productivity and sustainability.

Custom and Specialty Dock Door Solutions

Custom and specialty dock doors are built for certain domains. Where specific access system designs are needed, these doors are built to improve efficiency and safety in warehouses, maintaining performance in otherwise inaccessible areas. New technologies are improving energy efficiency features, including insulated and eco-friendly panels that minimize energy waste. Modern workplaces have close thermal and environmental requirements, which make these doors a good fit. Advanced access features also improve and automate control and lock security. Their designs make tailoring dimensions, configurations, and functions to meet any enterprise structure requirements. New dock doors improve efficiency and solve complex challenges for businesses.

Materials and Construction

Steel, Aluminum, and Composite Options

When constructing doors for warehouse docks, different materials such as steel, aluminum, and composite bring different advantages to different operational needs and environments.

Steel doors are very heavy-duty and secure, and can last a long time. This makes them great for applications where security and resistance to damaging and heavy-duty use are important. They work best for facilities that experience high amounts of people traffic and have a high risk of potentially damaging impacts.

Aluminum doors are also modern dock doors that are modern, and people like because they are lightweight and resistant to corrosion. They are also useful for environments that use or are around moisture, maybe even in a chemical state, interfacial area. They are more functional and presentable in such a case over the long term.

Composite doors are dock doors that use a mixture of lightweight high-performance materials. They provide distinct benefits such as less conductivity, noise cancellation, and less denting. Part of the reason these doors provide great conductivity resistance is because they are designed to provide energy efficiency, containment of more value, and to provide superior insulating value. These doors are very popular for use in facilities that require the safe, constant, and practical use of a wide range of temperatures or are designed primarily to store temperature-sensitive materials. Because of the very modern systems, advanced technology, and resources that are employed in all aspects of this, and the high standards set for the materials to be tailored to highly complex needs, systems to be designed for these, businesses can be sure to receive highly innovative and advanced systems designed for all the needs of dock doors.

Insulation, Sealing, and Weatherproofing Technologies

The insulation, sealing, and weatherproofing systems used on warehouse dock doors have improved to the point that these doors are now capable of functioning efficiently and effectively across a variety of climates and conditions. Polyurethane foams and polystyrenes are a couple of the thermal insulation products used to minimize heat loss and keep the interior of the warehouse at a constant temperature. Also, modern sealing systems such as perimeter gaskets, brush seals, and inflatable dock seals reduce the ingress of contaminated air, dust, insects, and moisture.

Weatherproofing systems incorporate advanced coatings and corrosion-resistant metals that increase the durability of dock doors in extreme weather. Thermal breaks and integrated water drain systems are modern construction techniques that provide extreme weather protection, assuring performance in wet, cold, and hot weather. Without a doubt, the combination of modern insulation, sealing, and weatherproofing techniques improves the energy efficiency, protection, and resultant lower maintenance costs of a warehouse.

Durability and Maintenance Considerations

Durability is the primary consideration when choosing warehouse dock doors with high volume and high-intensity traffic. Modern dock doors are fabricated with heavyweight and high-grade materials such as galvanized steel or aluminum, which do not rust and are not easily worn out with the passage of time. Advanced finishes, such as powder coat paint applications, make them even more scratch and chemical-resistant and more impervious to weather extremes.

Dock doors also require maintenance to outlast their predicted serviceable life. Routine evaluation of potential problems such as broken seals, inoperable or misaligned track systems, and worn structural or mechanical door components is a good maintenance practice. Assisting hinges and rollers with a lubricant of appropriate viscosity softens the sound and increases the frictionless motion; movement portions of the door are then more easily disengaged or moved, and extend their functional lifespan. Modern self-repairing panels and modular construction systems significantly reduce downtime, enabling lower cost and faster maintenance or repair to be performed.

Dock doors that incorporate durable materials, which are then complemented with maintenance, can together provide the highest level of efficiency and longevity. Subsequently, the operational reliability of dock doors, including overhead doors, is also maximized, and the repair cost is minimized over an extended time.

Applications of Warehouse Dock Doors

Distribution Centers and Logistics Hubs

Warehousedock doors are essential to the success of distribution centers and logistics hubs. These establishments flow and scale during busy periods and need care and attention to operational distribution. Dock doors are the pivot of entry and exit. High-speed dock doors and high-insulated doors are the necessary tools of a modern distribution depot, ensuring smooth warehouse loading and unloading processes. They improve the flow of operational distribution and stabilize temperature control, mitigating the risk of spoiled perishables. High advancements, Integrates with dock levelers, and vehicle restraints to improve the safety and accuracy of the operations. With e-commerce and global supply chain changes and demands, the value and worth of quality, dependable, energy-conservative, and high-tech doors to distribution hubs has only risen. With modern dock management, these doors streamline the distribution flow, improving dock throughput and lowering the distribution time.

Manufacturing and Industrial Facilities

Warehouse dock doors are essential for businesses, ensuring smooth and efficient goods movement and management in and out of warehouse spaces. These sleek doors are made for extreme usage and rough workplace conditions, which should be weatherproofed and sealed. Modern dock doors are built with high-tech features to keep your building as well controlled internally, with insulated and automated doors, weatherproof seals, and climate-controlled dock shelters. Furthermore, high-level warehouse management systems are capable of optimising and controlling every detail of your docks, and this is why integrating your newly purchased automated doors with top systems in the market is essential to ensure your operations are as smooth, safe, and economic as possible.

Cold Storage and Temperature-Controlled Warehouses

Warehoused dock doors must maintain exact temperatures for cold storage and temperature-controlled facilities. These dock doors are created using high-tech insulating materials, sealing mechanisms, and thermal barriers, enhancing the efficiency of warehouse loading operations. These strategic advancements prevent temperature changes and energy loss. By limiting the exchange of outside air with the controlled environment, these doors maintain the integrity of goods like food, pharmaceuticals, and chemicals, which are temperature-sensitive.

Reinforced dock doors are often used with emerging technology like high-speed doors, which further minimize exposure time and real-time monitoring systems to enhance energy efficiency. The smart technology integrated into these doors optimizes the entrance/exit of temperature-controlled storage facilities. These improvements to warehouse dock doors increase energy compliance, operational efficiency, and response to abnormalities, ensuring controlled storage facilities meet industry energy compliance and preserve operational integrity.

Retail and E-commerce Fulfillment Centers

In retail and e-commerce fulfillment centers, warehouse dock doors are key to moving and flowing inventory in and out of the facility, especially during peak warehouse loading times. Operators can load and unload shipments and move to the next in a matter of seconds, an absolute necessity in fast-paced environments. These modern doors can withstand the traffic while also keeping the facility secure and climate-controlled, a necessity when storing perishables or products that are temperature sensitive. Newer dock doors with automated systems, temperature controls, and real-time traffic monitoring boost efficiency and reduce wait times. Retail and e-commerce fulfillment centers are now able to invest in high-speed automated systems to meet their customers’ needs and provide fast and reliable fulfillment.

Installation and Maintenance

Professional Installation Guidelines

Site Inspection and Measurements

Conducting a thorough site inspection is necessary to ensure that the dock doors will be appropriately fitted and will conform to the specifications of the warehouse. For functionality, measuring the door width, height, and clearance appropriately is vital.

Material Selection

Materials of the highest quality need to be selected that best fit the specific requirements of the warehouse. For instance, insulated doors are best suitable for temperature-controlled buildings while impact-resistant doors work best for areas with a lot of traffic.

Equipment and Tools Preparation

All required tools and materials should be available beforehand to avoid hold-ups and streamline the installation. Tools and materials, from mounting brackets to bolts and other power tools, are essential.

Alignment and Balancing

The proper alignment and balancing of the dock door are central to the door’s future working. Leveling tools should be used to balance the door and ensure that it does not put strain on the components while working.

Safety Compliance and Testing

After installation, safety and functionality checks should be done to ensure that the dock door satisfies all requirements and is working appropriately. Automated systems, safety sensors, and emergency release systems should be taken into account in the testing for compliance.

Routine Maintenance and Troubleshooting

Proper attention to how warehouse dock doors are maintained is important to their long-term functioning and to the safe and efficient carrying out of warehouse tasks. Routine inspections and troubleshooting, along with repairs, do more breakdowns and intervals to add repairs. The bottom five are important for thorough maintenance and experience paperwork for troubleshooting:

Lubricate Moving Parts

Hinges, rollers, and tracks must be uniformly lubricated so as not to have wear on one part only. Also, use lubricants that are of high quality.

Inspect and Adjust Tension Springs

Worn torsion or extension springs should be replaced. The doors are opening and closing with tension that is smooth and not straining the motor.

Remove Debris/The Tracks Should Be Clean

Dirt, debris, and obstructions should be cleaned up from the tracks. Tracks must be wiped and aligned.

Test your Mechanisms to Ensure They Work

Workplace equipment and safety risks should be avoided, and this can be accomplished by accessing edge-detected safety devices and other emergency releases.

Inspect Your Cables and Hardware

Stress fractures, wear, and corrosion should be examined on brackets and cables. Fasten any parts that could cause operational issues.

Taking into account the hot and cold, the moisture and other environmental factors of your average warehouse, performing these tasks will keep your dock doors in the best conditions possible, saving time, money, and hassle in the long run.

Cost Considerations and Total Cost of Ownership

Considering the factors that impact the total cost of ownership of warehouse dock doors is critical in making the right decision. The following are five factors that relate to the cost of dock doors:

Initial Purchase Price

The most immediate cost is the purchase of the dock doors. Costs vary depending on size, materials, features, and other factors such as insulation or custom advanced safety features.

Installation Costs

Additional labor cost for the installation of dock doors also adds to the initial cost. These costs may increase if the dock door systems are complex or if the installation is custom-tailored.

Maintenance Expenses

There are costs involved beyond the immediate purchase that are also related to the maintenance of the dock doors. Over time, maintenance costs like lubrication, routine inspections, and may even be the replacement of parts. Downtime and maintenance neglect can be even more costly over time.

Energy Efficiency and Insulation

If your building has insulation, the internal temperature can be maintained at a more cost-efficient level. It may cost more in the initial investment of the dock doors, but energy savings can more than account for the costs.

Repairs and Down-Time Costs

The cost of repairs is bad enough, but the cost of downtime to a business can be a real killer. Malfunctioning dock doors can disrupt processes and lines of business, which can make the impact of these costs even greater.

Operators can evaluate the complete cost impact and understand the lifespan of dock doors while taking these considerations into account so that there is an appropriate trade-off between cost and functionality.

Innovations and Smart Technology in Warehouse Dock Doors

Automation, Remote Access, and IoT Integration

Incorporating remote-access automation and IoT into warehouse dock doors deepens operational efficiency and dependability. Automated dock doors support operational flow by increasing the speed with which doors open and close, reducing load/unload times. Adding remote access control from any location. This reachability of door control is a security plus.

With IoT, dock doors become data-driven enough to detect door, idle/active patterns, and prompt maintenance. Operators can be notified by sensors of misalignment or worn components, enabling corrective action to be taken before a malfunction occurs. These systems provide deeper functionality by syncing with Warehouse Management Systems (WMS) to manage and enhance operational productivity, ensuring doors are opened and closed at the correct times.

Innovations in dock door tech promote operational efficiency and uninterrupted workflow, but also warehouse safety enhancements. An IoT tech system can avoid damaging collisions by detecting active obstacles. This collision avoidance also mitigates the organization’s liability from operational incidents. Automated door systems are the latest in technology and operational efficiency to have fused multiple solutions to make warehouses operationally and functionally seamless, more than ever before.

Safety Sensors and Access Control Systems

Access control and safety sensor systems are vital to the functional operation of the dock doors in a warehouse. Safety sensors are designed to identify any presence or movement of equipment, personnel, and vehicles, eliminating the possibility of collisions. Incidents are further limited by only allowing the doors to open when the location is clear, by using various avoidance technologies like motion detectors, infrared beams, and image capture systems.

Access control systems manage the range of users and the operational ability of the dock doors. User access is controlled through keycard systems, biometric scanners, and/or advanced codes on keypads. Combined with warehouse management systems, the data of access usage is tracked, providing solid control and operational visibility. The protection systems, in tandem with the specialized software, make dock door operations as safe and efficient as possible.

Energy-Efficient and Sustainable Solutions

Modern-day warehouse dock doors are starting to be designed with energy efficiency and sustainability in mind. Modern insulation technology is used in these doors to help maintain internal temperatures and reduce the energy needed to heat and/or cool the warehouse. Heating and cooling energy is conserved with the use of high-speed doors. Their rapid movement, minimizing air exchange, is what makes them effective. Numerous businesses are now using recyclable materials and other energy-efficient technological innovations in the development of solar-powered dock doors and light-emitting diodes (LEDs) employed in the dock lighting. These energy-efficient and sustainable technological innovations are beneficial to a business’s bottom line operationally; however, these innovations also provide a business with environmentally friendly, sustainable partnerships.

Comparing Warehouse Dock Doors to Other Industrial Door Types

Warehouse Dock Doors vs. Standard Entry Doors

Warehouse dock doors offer high durability, security, and efficiency for logistics, while standard entry doors are cost-effective, versatile, and suitable for general access but lack the robustness and specialized features of dock doors.

Comparison Table:

| Parameter | Dock Doors | Entry Doors |

| Durability | High | Moderate |

| Security | High | Low maintenance costs can be achieved with high-quality warehouse doors. |

| Efficiency | High | Low |

| Cost | High | Low |

| Versatility | Low | High |

| Size | Large | Small |

| Installation | Complex | Simple |

| Usage | Logistics | General |

Pros and Cons for Different Warehouse Needs

Pros:

Better Longer Lasting

Over the years, dock doors have been made from high-grade materials designed to endure high levels of harassment from the elements, constant traffic, and impacts from forklifts and trucks. With these features, these materials ensure the long-term functionality of the doors within the harsh conditions of the working environment.

More Safety

The dock doors have specially designed and built robust safety features, with advanced safety locking systems designed to protect the warehouse storage and limit access to unauthorized personnel.

Faster Operations

The design of the dock doors greatly contributes to the seamless and quick movement of materials and goods in and out of the warehouse. It comes in handy in operational time savings, especially within logistics and distribution centers. Other learning advanced designs include seals and shelters within the doors to better assist in the movement.

Flexible Dimensions to Fit into Different Spaces

The design of the dock doors also assists in being flexible in designs to fit into different operational and shipping models. Depending on the vehicles in use, collection, and delivery, dock doors can be made to fit large trucks and even large cars to ensure movement is seamless and uninterrupted.

Protection from Environmental Elements

Insulation and weather resistance have been built into most dock doors, which keep the contents within safe from harsh environmental conditions.

Cons:

High Initial Cost of installing advanced dock and door products can be justified by long-term savings.

Advanced material, customization, and labor-intensive installations all make the initial cost of installing dock doors and their complex installation pricey.

Limited Versatility

Unlike entry doors, dock doors are designed with a logistics function in mind and cannot be used for other general access or varied general purposes.

Maintenance Demands

In dock doors that see high usage, operations can be halted by mechanical breakdowns on the rollers, seals, etc.

Complex Installation

Installation of dock doors can be complex. Structural changes to the warehouse are sometimes necessary, further increasing the installation cost and time.

Warehouse dock doors are critical in providing a high level of security and efficient logistics for buildings. However, for buildings with a smaller budget or infrequent unloading and loading, they may be inappropriate. Analyzing these pros and cons allows dock doors to be suited to the operational goals and needs of a business.

Market Trends and Future Outlook

Growth in Automated and Secure Door Solutions

Due to rising technological developments, automated and secure warehouse dock doors have had increasingly growing markets. There is a growing need for efficiency and safety in business logistics. While these advanced automations implement seamless movement in loading and unloading units. Such movements eliminate operational delays and increase reliability by alleviating manual movements. The operations are also enhanced with security mechanisms, as supply chain security is a growing concern. These security mechanisms include biometric access, RFID, tamper-resistant mechanisms, and movements that are easily seen and recorded.

On rapid expansion of e-commerce also shifts these automations. These systems need to help e-commerce vendors operate warehouses with dock doors that increase operational speeds and provide access to doors. Insulating designs increase energy efficiency while seamless automated doors help stay compliant with safety regulations. Smart technology integrated with doors provides operational data and monitors the system efficiency while also predicting the required improvements needed. These features integrated with doors are the future of warehouse infrastructure.

Leading Manufacturers and New Product Innovations

Rite-Hite

Rite-Hite is renowned for its cutting-edge solutions, including its durable and energy-efficient dock doors. Their latest product, the Barrier Glider series, features advanced insulation properties and integrated safety sensors, ensuring superior performance and reduced energy costs.

Hormann

Hormann specializes in high-speed and thermally efficient dock doors. Their Speed-Guardian™ series, introduced recently, boasts rapid opening and closing capabilities, enhancing productivity while minimizing energy loss in temperature-controlled environments.

Wayne Dalton

With an emphasis on innovation and reliability, Wayne Dalton offers a variety of commercial dock doors tailored to different industry needs. Their Model 888 ADV-Xtreme provides advanced wind load resistance and is uniquely designed for areas prone to extreme weather, making it a top choice among commercial doors.

Clopay

Clopay’s industrial-grade dock doors are built with durability in mind, and their Vertispeed® doors are a prominent example. These doors combine high-speed operation with heavy-duty performance to accommodate fast-paced warehouse environments.

ASSA ABLOY

ASSA ABLOY leads the market with its focus on smart, automated dock door solutions. The Crawford 600 series represents state-of-the-art design. Featuring IoT integration for remote monitoring and predictive maintenance, aligning with the latest technological trends in warehouse management.

SEPPES

SEPPES stands out as a premier provider of advanced industrial door solutions tailored for modern logistics and warehouse operations. Their high-performance doors are engineered for speed, reliability, and durability, featuring energy-efficient designs and cutting-edge safety systems. SEPPES integrates innovative technology into its solutions, offering remote monitoring and smart automation to ensure seamless operation in demanding environments.

Conclusion: Selecting the Best Warehouse Dock Door for Your Facility

Key Considerations for Facility Managers and Owners

Quality and Durability of Materials

If insulating and keeping temperature control of the interior space of the warehouse is essential to the business, investing in quality, high-volume, temperature-control insulated dock doors is key. Cold storage insulated dock doors are built with thick, durable, insulated steel. Quality and durable temperature control doors operate efficiently and last, protecting businesses. And warehouses from the many costs that come along with doors that require regular upkeep and maintenance. Research indicates that quality commercial doors reduce operational costs upwards of 30% during the door’s lifespan due to reduced maintenance.

Insulation and Saving Energy

Energy-efficient insulated dock doors equipped with high R-value doors retain and maintain interior space temperature. resulting in lower energy costs. Energy savings are significantly increased in cold storage facilities during docking and door operation.

Safety concerns

Prioritizing dock door safety is essential. Risks such as injury and accidents occur easily during. Choosing loading dock doors that are sensor-based for obstruction detection, have emergency release, and auto-closing features reduces injuries. Reports have shown that these features reduce loading dock injuries by 40%.

Efficiency and Speed

With the increasing need to control traffic flow in busy facilities, high-speed doors are crucial to increasing workflow. For operations that have frequent loading and unloading, rapid-operating doors greatly increase productivity, reduce downtime. And greatly reduce idling costs of waiting vehicles.

Options for Customization and Automation

Dock doors can now be personalized according to unique requirements like size and extra enhancements, such as remote monitoring and smart automated systems. Automation of entrance doors allows further integration with warehouse management systems and also improves operational performance of the whole facility by decreasing the need for manual handling.

Final Recommendations for Security, Efficiency, and Compliance

The three main things that I focus on when analyzing what the best warehouse dock doors are would have to be security, efficiency, and compliance. When it comes to security, I look for doors made of high-quality material and a locking system that is both advanced and easy to use. particularly for rolling dock doors. For efficiency, the best doors are insulated and have some or all of the following features: fast open and close capabilities and automation. Lastly, compliance is simply checking to see if the doors are up to the appropriate safety and industry standards. When security, efficiency, and compliance are all met with the right door. A solid decision can be made that will allow you to be successful for the foreseeable future.

Frequently Asked Questions (FAQs)

What are the benefits of using dock equipment at a loading dock?

Dock equipment, such as dock levelers, dock seals, and dock shelters, improves safety and efficiencies during the loading and unloading processes at the loading docks. Having seals and shelters properly fitted to the docks prevents loss of temperature control and weather damage to the products.

How do I choose the right loading dock door for my warehouse?

There are multiple factors to consider in choosing a loading dock door, such as the size, type, and operational requirements of the warehouse. Sectional dock doors are preferable in high-traffic openings, whereas rolling steel doors are a good option for security purposes. Analyzing the warehouse configuration and the precise requirements regarding loading and unloading operations is essential in choosing the most appropriate option.

What types of dock levelers are available for industrial docks?

Choosing the most appropriate type of dock leveler can provide a tremendous improvement in efficiency in your loading dock operations. These include mechanical, hydraulic, and air-powered levelers, each of which has unique advantages in terms of user-friendliness, load capacity, and other features.

How do dock seals improve energy efficiency at warehouse docks?

Dock seals protect the temperature within the facility and reduce energy costs. These seals provide a complete air and weather barrier during loading and unloading operations with warehouse loading equipment, which saves energy and protects the surrounding products.

What are the common door services available for warehouse dock doors?

Services most often offered for warehouse dock doors include installation, maintenance, and repairs. Having regular maintenance scheduled is an easy way to keep dock doors operational and prevent costly repairs from emergency repair situations. In order to keep business operations flowing, service teams can provide emergency repairs.

How can I enhance dock safety at my loading dock?

To keep dock areas as safe as possible, having safety procedures in place, safety bumpers, and docks operational is a must. Safety is heavily dependent on training employees to safely load and unload. As well as doing regular maintenance on the dock equipment.

What are the features of sectional dock doors?

Sectional dock doors are made from a series of panels that are designed to roll up vertically, allowing for maximum overhead space. These doors are built for heavy use and can be made with insulation to save on energy loss. Warehouses that frequently open and close to the outside will appreciate the climate-controlled environment and the garage’s security.

Why are rolling steel doors a good choice for commercial facilities?

Custom rolling steel doors are a staple in large commercial buildings like manufacturing plants. Their heavy-use construction is one of a kind. is their Custom MSizing: they can fit almost any door space to offer protection to the building’s valuable assets.

Reference Sources

- Loading Docks and Warehouses | Ohioline – A resource from Ohio State University providing insights into warehouse and loading dock safety and design.

- Loading Dock Design Guide – A detailed guide on loading dock design, including key components and best practices.

- Configuring Traditional Multi-Dock, Unit-Load Warehouses – An academic dissertation focusing on multi-dock-door warehouse configurations.

- Loading Dock Safety Reference Guide – A safety guide from the University of California, Irvine, covering loading dock safety measures.

- Loading Docks | Occupational Safety and Health Administration (OSHA) – OSHA’s interpretation of safety standards related to loading docks.