For loading dock operations, efficiency, and safety rules. Companies depend on well-oiled, streamlined systems for the quick, safe movement of products, personnel, and equipment. Damage is also. This is where hydraulic dock plates come into. Advanced tools have changed how companies deal with loading and unloading movement tasks. The hydraulic dock plates deliver a sturdy, seamless system for bridging a (various) vehicle (type) to (different) dock(s). This piece will examine the hydraulic dock plates’ greatest advantages and defend why they should be among the first for workplace safety, and how operational efficiency is addressed.

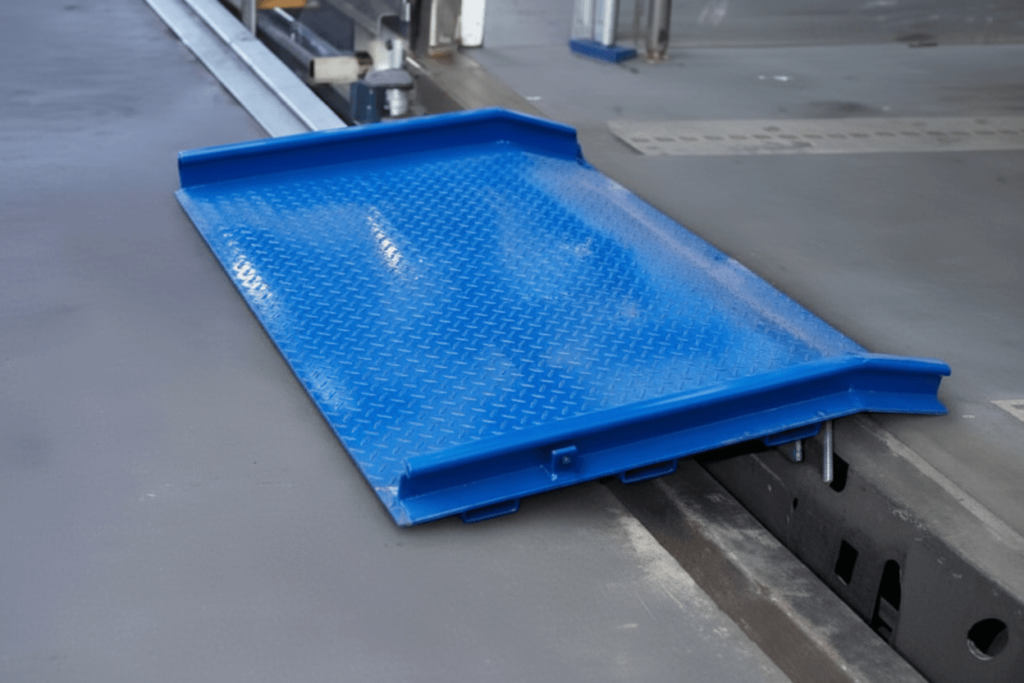

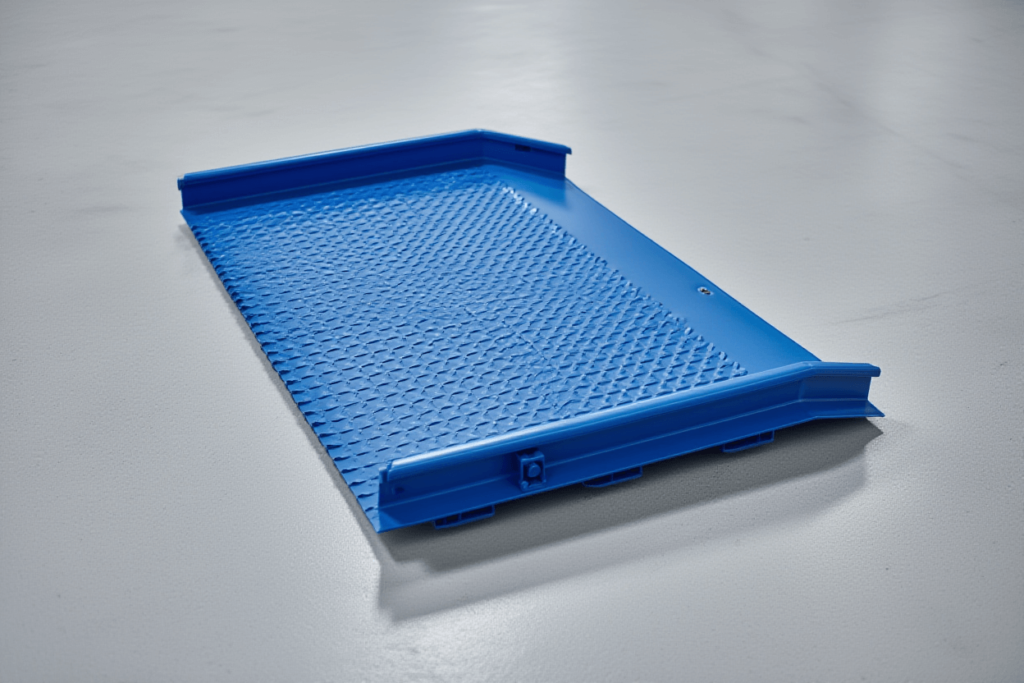

What Is a Hydraulic Dock Plate?

A hydraulic dock plate is a vital tool for the safe and effective movement of products between a truck and a dock. Automated hydraulic dock plates differ from other hydraulic dock plates because the working of hydraulic cylinders allows the dock plate to self-adjust to the height of the truck bed, and there is no need for manual repositioning supplementation. It reduces the risk of injuries and creates a clear flow of work. These dock plates are fully customizable and top-of-the-line, for varying degrees of load weight and greater resistance to daily and repetitive abrasion and thus are a top choice for a multitude of distribution centers and logistic centers around the world. Ultimately, modern hydraulic dock plates are designed and equipped with safety standards that are required in high-risk work locations like distribution and logistics centers.

Definition and Core Functionality

Hydraulic dock plates are engineered to make the moving and handling of materials safer and more efficient. Walking and moving materials off and onto vehicles are potentially dangerous activities. Walking on and off the dock on vehicles that move and shift loads, and standing in the docking area must be done at the same height are serious safety risks. Getting the height of the vehicle safely and quickly, and setting the workers to safely walk on the unit, is the goal. Balance and height are adjusted automatically with hydraulic controllable units that are vehicle height adjustable. The pieces made of steel and aluminum withstand the wear of the moving and handling tasks. Increasing the safety of the product with pressure reliefs that relieve built-up pressure along the hydraulic systems quickly and safely, and overload protection devices are defined to make it more user-friendly.

Difference Between Dock Plates, Dock Boards, and Dock Levelers

The customer’s needs will dictate what product they will use. A dock level, dock plate, or dock board can all fill the space between a loading dock and a truck, but they have differences that will determine which product will suit their needs best.

Dock Plates

Dock plates, typically made of aluminum or steel, are flat portable structures that only cover small height gaps. They are used to cover small height differences between a dock and a trailer. They should only be used for light loads like hand trucks and dollies. They are meant to be used on areas of a dock that are used for loading and unloading movements. Because of the amount of weight they can handle, they should NOT be used on areas of the dock that are used to offload heavy machinery.

Dock Boards

On the other hand, dock boards are built to handle more weight. They are also reinforced with heavy-duty aluminum or steel and have curbs along their side. These curbs act as a buffer to stop large machinery from accidentally driving off the side. These dock boards are able to be used in industrial areas that need to transfer large quantities of materials constantly.

Dock Levelers

Dock levelers are installation fixtures on the roof of the building loading sections (or loading docks) that help level large gaps between the dock and the beds of the trucks parked at the loading docks. Leveling of the dock’s height is done by hydraulics, air-powered, or mechanical means to smoothly adjust the level of the dock. This feature is applied to advanced safety amenities, durability, and continuous load management. This is done in highly operational sectors like warehouses and distribution centers.

Every dock equipment category serves a particular purpose. The right choice depends on the load configuration, operational frequency, and patterns. Each of the equipment categories is designed to optimize the operational safety and efficiency of the docks. This is highly valuable in equipment that is used in different industrial dock settings.

Key Features and Benefits of Hydraulic Dock Plates

Smooth and Efficient Operation with Hydraulic Power

Hydraulic dock plates are built to facilitate uninterrupted and reliable use and to bring ease to the work that remains to be done during strenuous working hours in an industrial or warehouse setting. Because of the nature of their design, dock plates that use hydraulic power and are more easily adjustable are more desirable for extensive industrial work. Here are five more observed features of hydraulic dock plates:

User-Friendly Automation

Mercy, are the hydraulic dock plates painless to control? The control for lifting and lowering the dock plates is a push button. This eliminates the manual lifting and lowering of the dock plates, an action that can result in physical strain.

Heavy Duty, High Load-Bearing Capacity

These plates are built to accommodate the increasing demand for heavy loads in the warehouse and industrial sectors. The load capacity for these plates can go anywhere from 20,000 lbs, 40,000 lbs to even more.

Safety Control Systems

Every hydraulic dock plate is built with control systems that take control of the dock plate’s automatic and manual systems to help prevent operation accidents and to control the lowering and lifting of the plates.

Extended Life Span

The heavy-duty steel, which is rest-proof, is engineered to be used in difficult industrial conditions for extensive periods of time. It is built for an extended life span.

Efficient Leveling Systems

The precision and smoothness of the hydraulic systems in use are what allow lowering and lifting of the plates.

These features listed are what make dock plates are great addition to any business looking to improve the convenience and ease of unloading and loading in their industrial and warehouse jobs.

Improved Safety for Workers and Cargo

Hydraulic dock plates come with built-in safety features that protect your workers and cargo while they are being loaded and unloaded. Here are a few safety features to note:

Anti-Slip Surfaces

Coatings that are anti-slip or have a specified tread design allow your workers to maintain a firm foothold on the dock plate surface. Footholds give workers a firm foothold on the dock plate surface. Footholds give workers a firm foothold on the dock plate surface and prevent slipping and falling.

High Load Capacity

Every hydraulic dock plate is designed to securely and stably transfer a large cargo load and equipment to another dock or cargo vehicle, often utilizing lip extension functions with hydraulic cylinders.

Safety Guard Rails

Some hydraulic dock plates come with side guard rails or side curbs to help stop cargo from slipping and falling off the dock plate. This is to help avoid damage to the cargo or accidents.

Emergency Stop System

Hydraulic dock plates come with emergency stop systems that eliminate all functions with an emergency stop in case there is an emergency failure. This prevents additional damage and protects the workers, ensuring their safety around hydraulic pump and motor stations.

Enhanced Visibility Markings

To help operators or forklift drivers see where the key areas of the dock plate are, bright, durable markings are used. This helps to avoid misalignment or mistakes.

With features like these, timeless hydraulic dock plates help to create a reliable and safe workplace for warehouse workers, operating forklifts, and the cargo being moved.

High Load Capacity and Durability

Hydraulic dock plates are constructed carefully to provide extreme durability and the ability to handle various weight ranges over extended periods of use. Below are several highlights and specifications that capture heavy load-bearing and strong construction.

Heavy Load Capacity – Special construction allows this dock plate to handle weight ranges upwards of 15,000 pounds, which makes heavy machinery and giant shipments very easy to handle.

Steel Construction – Because of the reinforced, high-tensile steel construction, users will be able to use this dock plate for extended periods of time and be resistant to bending, warping, and other wear issues common over time.

Durable Dock Wear – Corrosion and wear become non-troublesome because of the protective covering worn per dock plate that fights off issues/attacks that the extreme weather and other environmental situations would throw at any plate.

Impact Absorption – Impact forces are distributed and absorbed by the dock plate due to the design, thus preventing excessively damaging stress from being concentrated in one area, avoiding premature failures.

Heavy-use hinges – Opening and closing the plates to make a smooth transition and reduce stress should be the goal when using dock plates, and the proper heavy-use hinges have been constructed to do this. All of the above constructions, as described, make this plate able to withstand the above-described weight limits.

Because of all of the above-described and detailed features, this dock plate should be considered as one of the most reliable in the construction and industrial fields.

Reduced Manual Labor and Ergonomic Advantages

Hydraulic dock plates improve the flow of work operations and reduce the physical demands of work for dock workers. For these reasons, the use of hydraulic dock plates helps create a more positive work environment. Below are some of the most positive impacts of using hydraulic dock plates.

Less Physical Work – hydraulic plates help reduce the physical demands for the workers because they won’t have to manually move heavy plates for every load and unload.

Faster Work Flow – There are automation systems that adapt to the rate of work being done, resulting in a dock plate system that optimizes and saves time in busy operations.

User Friendly – Work systems should help improve work posture and work safely, so hydraulic plates are designed and built to be easily manipulated.

Fewer Worker Injuries – Reducing the manual work that is often too heavy for a person to perform results in less damage to the workers.

Improved Efficiency and Control – Fewer workers are needed to load and unload due to the dock plate hydraulic systems that handle different heights and weights.

Overall, these are the most important reasons hydraulic dock plates are great for industrial work.

Types of Hydraulic Dock Plates

Standard Hydraulic Dock Plates

Common hydraulic dock plates are great for covering the gap between transport vehicles and loading docks. Plates are made of the finest quality materials and are adjusted to fit every dock and transport trailer. Some plates even have locking systems that prevent trailers and dock stalls from moving to prevent accidents. Many of them are created to be easy to use and fit any industry’s equipment. Integration of top-notch actuators makes these dock plates low-effort.

Common hydraulic dock plates are ideal for almost any industry, including manufacturing and transportation. These plates are built to last even in the toughest conditions and avoid any performance diminishing. This ultimately makes them the ideal option for any business that aims to upgrade the existing work systems.

Heavy-Duty and Extra-Wide Models

Extra-wide dock plates are also hydraulic and heavy-duty duty made to fit the requirements of clients dealing with oversized and oversized loads. This model comes with reinforced steel or aluminum construction. We take pride in being able to support higher weight capacities while still keeping structural integrity. This model is designed to fit between docks with oversized aluminum and steel structures. These dock plates are made to fit gaps where standard plates no longer work.

We also add features like anti-slip surfaces to increase safety and heavy-duty bumpers to protect your bottom line while our dock plates are being moved. Models not only meet regulations but are made to last in high-wear and high-traffic environments. Whether you work with large heavy machinery or are in a large distribution center, you can fully expect these dock plates to work in any high-duty application.

Custom and Specialty Configurations

Custom and specialty hydraulic dock plates are made to meet the particular needs of some business steps and offer custom solutions for different industries. Customizations in dock plates include the size of the dock plate, weight capacity, and material construction of the dock plate to match different types of machinery, vehicles, and conditions. Usability of the dock plates and worker protection during usage are creatively enhanced by the use of anti-slip surfaces, safety edges, and systems for shock absorption in the dock plates.

Specialty configurations to address particular ”difficult” working situations, such as refrigerated warehouses and hazardous material handling. Dock plates made for this have customizations like specific coatings and materials that resist corrosion, and more materials that resist breakage under extreme temperatures. Because of the versatility, these dock plates are custom-made to support workflows and help manage the loading and unloading chores of business operations in highly tailored situations.

Materials and Construction

Reinforced Steel and Heavy-Duty Components

Steel dock plates are built within a warehouse or shipping dock by utilizing reinforced steel and lifting components. Steel and reinforced components hold in place and give the dock plates the ability to hold heavy weights. These plates are built and crafted intimately by hand welding and supporting storage techniques to reduce and ever-increasing the capacity and wear and tear. Heavy components spawn large working hinges and then even larger lifting hydraulic components to establish storage stability. New files within the plates hold more of an edge and even surfaces on a dock. These plates are built to sustain and even increase the ability to dock and hold weights within high storage environments.

Surface Texturing for Anti-Slip Safety

To guarantee safety with dock bed plates, surface texturing must be taken into account, particularly for pit mounted dock levelers. Staff and employees require protection and additional safety features. Textured patterns such as diamond plates, raised tread surfaces, and modern innovations with anti-slip properties and materials that keep their diamond plating for long enough, offer coatings with anti-slip attributes. Environments with slips and falls, moisture, grease, and dirt accumulate on tread surfaces. These patterns are excellent to avoid having to deal with a workplace unsavely designed. Textured surfaces and safety standards guarantee contractility. Designed for anti-slip attributes to provide protection for employees and industrial workers, workplace safety.

Corrosion Resistance and Longevity

Even more so than other types of equipment, hydraulic dock plates get moisture, temperature swings, and chemical exposure, all of which lead to corrosion. Makers meet this head-on with advanced corrosion-resistant materials and coatings to ensure these plates last as long as possible in the more extreme parts of industry.

Hydraulic dock plates also get all of the advanced, low-wear, low-maintenance corrosion-resistant materials to ensure that they last a long time. These low-maintenance materials help ensure longevity. This advanced low-wear construction also puts materials in the plates that help lower the maintenance to just routine cleaning and lubrication.

These plates stay reliable and withstand extreme use. Construction integrated long-lasting components that ensure they also withstand rugged, even extreme, use of years of deployment in the most harsh environments of industry. Because they get extreme use and stay reliable, they have a long service life and low cost.

Applications of Hydraulic Dock Plates

Warehouses and Distribution Centers

Hydraulic dock plates are amazing products that help warehouses and distribution centers work. Because of how busy these places are and how quickly they need to get shipments in and out, the ability to easily and quickly move from the loading truck to the loading dock is very important. These hydraulic dock plates help make this process easier, smoother, and most importantly, bridge gaps safely.

Modern technology provides these dock plates with things like automatic features, customizable heights, and support for heavy loads. These plates work with all kinds of loading equipment, like forklifts and pallet jacks, which makes things run super efficiently. Because of these dock plates, warehouses can run better and more efficiently, which makes the entire supply chain work more easily.

Manufacturing and Industrial Facilities

Hydraulic dock plates play a crucial role in factories and industrial sites by enabling smooth movement of heavy items between trucks and loading docks. Their advanced hydraulic systems adjust height quickly and easily, allowing them to handle a wide range of truck sizes. Because forklifts and pallet jacks operate around them, these dock plates are built to support heavy loads safely and reliably. They improve workplace safety, boost productivity, and reduce the need for manual handling. Newer models also include remote controls and upgraded safety features for easier and more secure operation.

Retail and E-commerce Fulfillment

Almost all retail and e-commerce fulfillment operations utilize Hydraulic dock plates, which perform the essential function of creating a stable bridge for the safe and efficient transfer of goods between the dock and the delivery vehicle. With the rapid pace of the industry and a competitive market, these plates have been in increasing demand. They have played a crucial role in responding effectively to the rapid online shopping surge and the need for prompt deliveries.

Industrial hydraulic dock plates are built to withstand the constant extreme operations of a retail fulfillment center and an e-commerce warehouse. They are designed to improve operational efficiency and reduce worker fatigue, as well as reduce workplace accidents. Operational efficiency is maintained with new features and enhancements like automation, premium, costly safety dock plates, and improved rugged structures.

Automated conveyor systems, forklifts, and pallet jacks are easily integrated with these dock plates, which are designed to high standards. Reliable and safe digital commerce systems are built with these dock plates.

Cold Storage and Temperature-Controlled Operations

Hydraulic dock plates are essential in cold storage and refrigerated operations. Dock plates keep the integrity of perishables as they serve as a reliable bridge for smooth loading and unloading. Crafted to battle extreme temperature variations, hydraulic dock plates are built with strong, corrosion-resistant materials that maintain effectiveness in freezing and chilled situations. In addition, their ability to handle heavy loads secures the products from damage that is normally caused during transfers. Thanks to the sophisticated hydraulic systems, these dock plates improve operational speed and safety. This allows companies to keep their

Installation and Maintenance

Professional Installation Guidelines

So you bought a new hydraulic dock plate and now must install it. You want to do it correctly so it lasts and works as it should. Follow these guidelines and basic safety rules to do the job right.

Inspection and Prep

You should be able to tell at a glance if the dock plate will work at the dock area. Then you will want to examine the area where you will install the dock plate to make sure it is level, clean, and free of any obstruction. If you skip any of those things, you will have problems later on.

Load Capacity

Make sure the dock plate will be able to handle the weight you will need it to handle. Look at the specs of the dock plate to know what the weight capacity is and ensure that the max weight of the loads and any equipment will not exceed that.

Anchoring

Make sure you have the right dock plate bolts and follow any other anchoring methods that the instructions say. Move the dock plate as little as possible when you are tightening the bolts to avoid the anchored parts from moving.

Connecting the Hydraulics

You need to pay careful attention to specifying if you wish to avoid operational mayhem and encourage hose alignment and fitting attention.

Testing

Once everything is set up, do a test of the system to make sure the hydraulic parts are moving as they should. Then make sure the controls to the system, the safety controls, and the system are all functioning as they should.

Putting these detailed instructions into action will allow businesses to achieve the safe and effective setup of hydraulic dock plates and increase operational productivity over the long term.

Routine Maintenance and Troubleshooting

How to Troubleshoot Hydraulic Dock Plates

To guarantee the effectiveness and safety of hydraulic dock plates, certain maintenance and mitigation practices must be followed. The following are five of the most important maintenance and mitigation practices:

Check and Maintain Hydraulic Fluid Levels

Check the hydraulic fluid reservoir periodically to make sure it is at the recommended fill level, especially for hydraulic dock levelers that are push-button activated. If the fluid level is too low, the system will perform at a suboptimal level, or worse, completely fail for a certain period of time. Fluid levels should be replaced or topped off with the hydraulic fluid recommended by the manufacturer.

Check Seals and Hoses

Check seals and hoses for signs of wear, and make sure that no leaks or damage are present in the hydraulic pump and motor stations. Loose fittings and cracks in the system can cause a loss of pressure, which will cause the system to operate at a lower level of efficiency. Replace damaged seals and hoses in a timely manner to prevent system damage.

Dust all Moving Parts and Surfaces

Make sure that dust, dirt, and debris are not present among the surfaces and moving parts of the dock. An obstruction of dirt can cause the operation of the dock to become smooth and can cause parts to wear prematurely.

Check the Functionality of all Safety Features

Testing the functionalities of all safety features, such as the emergency stop system, fail-safe systems, etc., is vital to prevent potential safety hazards. All safety features should be operational prior to use.

Check Hydraulic Cylinder Performance

Check the hydraulic cylinders for odd sounds, irregular movement, and leaking fluid. These might be signs of internal damage or worn seals that need to be fixed to avoid problems with the system.

Keeping to this maintenance and troubleshooting plan helps companies to get the most use out of their hydraulic dock plates and helps to keep the business running smoothly and safely, particularly with push-button activated systems.

Cost Considerations and Return on Investment

Investing in hydraulic dock plates holds value for the long run from a business perspective. Knowing the cost and possible return on capital invested (ROI) is equally important. Here are five factors to consider:

Initial Purchase Price

Restrictions on size, load capacity, and brand cause a significant upfront investment in hydraulic dock plates. These plates range in price from $5,000 to $20,000, and in some cases, more than that.

Installation Costs

Installation is needed to ensure that the dock plate is being used to its maximum potential. Without proper installation, costs on efficiency can range from $1,000 to $5,000, in addition to preparation and labor costs for the site.

Maintenance Costs

To keep dock hydraulic plates functional, there is a need to perform maintenance. Usage and wear vary, but a good prediction for the annual costs of maintenance is between $200 and $1,000.

Energy Consumption

I’m sure you can see that to keep hydraulic systems running, there is a need for some sort of power or fuel. Even though systems are running efficiently, the annual costs of energy consumption, in $100 to $500 range, should be considered.

Operational Downtime

Hydraulic dock plates can make the process of loading and unloading much easier, which in turn reduces worker fatigue and increases productivity. Because of the streamlined process and the cut in labor costs, a business can predict a ROIC of 20-30% annually when using leading manufacturers of loading dock equipment.

By assessing these factors, companies can make rational assessments, weighing the upfront costs and operational efficiencies and monetary profits that hydraulic dock plates provide.

Safety Features and Compliance

Safety Locks, Guard Rails, and Emergency Stops

Hydraulic docks stay firmly in place during loading and unloading, and guard rails protect equipment and personnel from slipping off the dock edge. Emergency stop buttons let operators halt the system instantly to prevent dangerous movement and avoid accidents. Together, these features create a safety system that aligns with OSHA requirements and other safety standards. To keep everything functioning properly, operators must regularly inspect and maintain all safety mechanisms throughout the dock’s service life.

Compliance with OSHA and Industry Standards

Hydraulic dock plates help make redundant and dangerous loading and unloading tasks quick and simple for workers in warehouses and docks. They make these tasks safe and effective. Because these dock plates play such an important role in workplace safety, they must fulfill OSHA requirements like 29 CFR 1910.26, which includes details like how strong the dock plates must be and how much weight they must be able to stand without substantial risk of failure or oversight. Furthermore, they need to have sufficient safety locks so as not to slide or shift while in use.

In collaboration with OSHA, the American National Standards Institute (ANSI) outlines and sets criteria like safety, strength, and stall structure, along with the need for ongoing inspections that must be complied with by all dock plates in the industry. Furthermore, these criteria require all manufacturers to appropriately identify their products by adding signs that explain how to use the product, along with the weight of the product and the weight of anything that can be added to the product.

All of the criteria and standards do not make the work in the dock industry more complicated. They actually provide for a much safer and efficient workstation by reducing risk and injury to dock workers and by reducing the need for work downtime. In addition to meeting industry benchmarks, all industry workers must be trained in the safe and proper use of the dock plates in order for a worksite to truly be safe and efficient and in OSHA compliance.

Innovations and Smart Technology in Hydraulic Dock Plates

Automation and Remote Control Integration

Also, upgrading efficiency and safety is the automatic and remote-controlled technology for inoperable hydraulic dock plates. Systems allow dock plates to be adjusted remotely from handheld devices and central control panels. Doing so lessens the need for manual operating controls and reduces human error and physical exertion.

Automated hydraulic dock plates can store different sequences of commands and adjust the operations for individual loading and offloading tasks and different load types. Ordinarily, hydraulic dock plates can weigh and monitor the health of their operations, and sensors can report the data to the Internet. With intelligent devices, workplace efficiency and safety are enhanced in warehouses and distribution centers. These data systems allow maintenance to be scheduled predictively and reduce the need for opportunistic preventative care.

IoT Monitoring and Predictive Maintenance

The installation of IoT integrated hydraulics in docks in numerous warehouses and distribution centers has changed the layout and operation of docks in warehouses and distribution centers. Through the use of individually IoT-connected load cells to measure the weight load as well as advanced sensors to measure the angles of the hydraulic plates and stress levels on the hydraulic plates in real time, warehouse and distribution center managers can receive real-time updates on the load being placed on their hydraulic plates. This allows warehouse managers to identify and rectify problems in overloading, wear and tear, before they cause downtime or equipment failure.

The IoT dock plates allow for predictive maintenance, unlike other systems without such advanced technology. It allows maintenance to be forecasted, and the costs of maintenance to be forecasted, and the costs of maintenance in the future to be planned, along with unplanned renovations to be avoided. Predictive maintenance can be used with plates of docks that possess excessive vertical or horizontal mechanical strain, along with the dock plates, to receive warning messages to alleviate contact with other negative mechanical systems. Predictive maintenance can be used on systems with strain plates on systems and eliminates the need to inspect the systems regularly, reducing the costs of inspections.

When blended together, Internet of Things technology and predictive analytics can help ensure that hydraulic dock plates can be pushed to their limits and still perform their function reliably and safely. The integration of these predictive analytics systems is an innovation as companies adjust to the demands of smart and connected supply chains.

Energy-Efficient and Eco-Friendly Options

Hydraulic dock plates are designed with sustainability in mind. Many manufacturers have begun integrating a variety of new energy-saving technologies. Smart hydraulic systems are designed to save energy by switching hydraulic power off when the system is idle. Eco-conscious dock plates are designed to use plastic hydraulic fluid. Most dock plates contain recyclable plastic, and some modern dock plates are made entirely from recycled plastic. Solar-powered dock plates are designed to reduce the use of non-renewables.

The use of energy-saving, new eco hydraulic dock plates reduces conventional energy use and brings cost savings through reduced energy bills. Innovations such as these bring savings through compliance with green energy regulations.

Comparing Hydraulic Dock Plates to Other Dock Equipment

Hydraulic Dock Plates vs. Mechanical and Manual Dock Plates

Hydraulic dock plates offer automation, durability, and efficiency for high-volume operations, while mechanical and manual plates are cost-effective but require more physical effort and maintenance.

| Parameter | Hydraulic | Mechanical | Manual |

| Operation | Automated | Manual chain | Manual |

| Durability | High | Moderate | Low |

| Efficiency | High | Moderate | Low |

| Cost | High upfront | Moderate | Low |

| Maintenance | Low | High | Moderate |

| Safety | High | Moderate | Low |

| Usage | High-volume | Medium-volume | Low-volume |

Choosing the Right Solution for Specific Operations

When it comes to choosing the right hydraulic dock plates, it is important to identify the specific needs of the operation to attain the desired performance, safety, and economic advantages. Here are five major factors to help in this decision:

Weight Limit

Being able to handle very high load capacities, the weight requirement of the operation should include the maximum weights of the forklifts and the cargo to ensure the dock plate is designed for heavy and hydraulic plate usage.

Volume of Activity

For operations with high volume loading and unloading, hydraulic dock plates are able to provide the durability and efficiency to seamlessly handle the heavy and frequent operations.

Differences in Dock Height

Automated adjusting hydraulic dock plates are equipped for smooth transitions and excel in settings with different levels of dock and truck beds and over height.

Safety

While hydraulic dock plates without a safety measure are already the safest option, with additional features for safety like automatic lip locks, side guards, and an emergency stop, it elevates safety further.

Maintenance

If low maintenance is a requirement, choosing hydraulic dock plates can be the right option, as hydraulic systems usually require less maintenance than mechanical ones.

These factors demonstrate the benefits hydraulic dock plates offer in extremely high-performance situations while also being flexible, safe, and economical.

Market Trends and Future Outlook

Growth in Automated Loading Dock Systems

How is the shift towards automated systems changing warehouse and logistics operations? How are hydraulic dock plates evolving? Is the demand for operational efficiencies, improvements in workplace safety, and streamlined supply chains driving the trend towards dock automation? How do Modern hydraulic dock plates decrease operational downtime and increase efficiency?. Today, the intractable hydraulic dock plates of the modern dock leveler are integrated with the latest technologies, adding soft automation and the Internet of Things (IoT) sensors to the real-time programmable systems used in business operations to not increase, but instead decrease the operational downtime and increase efficiency.

Recent Market Report states, “ Automated systems are based on the need for rapid, low-cost and low-touch loading and unloading of containers.` Durability and versatility characterize hydraulic dock plates of varying sizes and configurations. All are designed to provide real-time control and differential rating systems to automated hydraulic warehouse setups. Advocating for energy-efficient hydraulic systems aligned with modern sustainable goals is the ongoing societal trend. Automated systems increase hydraulic plate versatility.

Throughout the world, the modern philanthropic warehouse or distribution center of the 21st century is Automated systems plus the dock plate.

Leading Manufacturers and New Product Innovations

Rite-Hite

Rite-Hite is the world’s largest provider of hydraulic dock plates and other loading dock equipment. The Rite-Hite philosophy is centered around innovation, safety, and energy efficiency. Energy-efficient dock plates with automated hydraulics and other advanced safety features for automatic positioning and load sensing are some of the latest innovations on the market.

Bluff Manufacturing

Bluff Manufacturing offers fully hydraulic dock plates designed for durability and customization. Bluff is recognized for its modular, robust design and is known for its latest efficient and low-downtime offerings on the market for adaptable dock solutions: a design that improves configurability to a wider range of warehousing challenges.

Pentalift Equipment Corporation

Pentalift is recognized for its dock plate technology and is one of the first to offer an environmentally sustainable option with the new hydraulic technology on the market. Their modules are designed not to compromise energy efficiency trade-offs on the new units.

Kelley Entrematic

Kelley Entrematic focuses on safety and efficiency with its hydraulic dock plates. Their new systems employ precision hydraulics for better control and longevity of the equipment. They also use more recyclable materials in their products.

Serco

Serco dock plates are known for their heavy-duty, high-capacity designs. Their innovative systems also introduce multi-level safety systems, user-friendly interfaces, and digital control panels for high-speed distribution center operations.

These companies keep innovating in hydraulic dock plate technology for warehouses and distribution centers to have fast and safe, and sustainable technology.

SEPPES

SEPPES has been innovating in the hydraulic dock plate industry for many years. They have incorporated technology and engineering to produce highly durable, accurate, and simple product designs, and have a reputation for being user-friendly for warehouses and logistics centers. With a focus on safety and efficiency. SEPPES integrates automated systems. Energy-friendly, and higher load systems, and has built a reputation as the best for extreme performance work.

Conclusion: Selecting the Best Hydraulic Dock Plate for Your Facility

Key Considerations for Facility Managers and Owners

Choosing the right hydraulic dock plate for your facility requires looking at a variety of aspects that match the needs of your operations. The following are the five factors to consider the most:

Load Capacity Requirements

Consider the maximum weight that the dock plate will support as part of your daily operations. The dock plate will need to have a weight capacity that exceeds what you will consider your heaviest loads for safety and multifunctionality.

Size and Dimensions

Be sure to consider the height difference between your dock to the vehicles, along with the width of your loading area. The dock plate will need to be large enough to fit the area so that all passes will be completed without issue.

Material Durability

For the construction of the hydraulic dock plate, you should select high-quality materials like steel and aluminum. Steel is better suited for heavy-duty uses, whereas aluminum would be better for a more moderate usage scenario.

Energy Efficiency Features

For energy-saving systems to be of use to you and your facility, hydraulic dock plates should have systems that help save energy.

Safety Enhancements

Dock plates should have features like an anti-slip surface, side guards, and an automatic emergency stop to avoid accidents. This makes a better working environment for employees.

If managers and owners zero in on these aspects. They can be educated in choosing a hydraulic dock plate with the greatest benefits to productivity, overall safety, and operational durability.

Final Recommendations for Safety, Efficiency, and Value

Based on your needs, I have tailored my criteria to be composed of. In my opinion, the three most important aspects. These aspects are efficiency, safety, and cost value. Safety-oriented features I look for are anti-slip surfaces, side slip emergency stop features to reduce accidents. Efficiency features are high load capacity, smooth functional flow, and overall workability integration that complements my features. Cost value is based on overall durability, required upkeep, and total predicted costs for ownership over time. This allows me to select hydraulic dock plates that meet my criteria for personal needs and safety without hassle in the future.

Frequently Asked Questions (FAQs)

What are mechanical dock levelers, and how do they compare to hydraulic dock levelers?

Anchor levelers use a spring device to create a ramp between the loading dock and a truck, while costing the least. as there is no need for an electric hydraulic system. Hydraulic dock levelers use a system of hydraulics and a pump and motor to elevate the leveler and automate the deployment of a bridge at the front of the leveler. While mechanical levelers are reliable for lighter and more consistent loads, dock Levelers with more suitable for busier areas with loading holes. Where more frequent use is present, and heavy trucks are more efficient, as their use is more Hydraulically operated.

How does a hydraulic dock leveler or loading dock leveler operate?

A fully powered, hydraulic dock leveler will fully deploy the deck to sit idle while fully using hydraulic pumps to provide a consistent lowering for a proper sit to the deck. These fully controlled, fully powered dock levelers are especially suited for the more demanding work environments.

Are vertical storing dock levelers or pit leveler designs better for my store or facility?

While each style of Vertical Storing Dock Levelers and Pit Leveler designs has its pros and cons, no one does it better than ELS. Facilities that require unobstructed pit access due to environmental or sanitary control issues benefit from retractable, vertical-storing dock levelers. Conversely, pit-mounted dock levelers and other variants of pit levelers deliver a completely flush-mounted appearance. Additionally, they can integrate insulation and weather stripping to further enhance their environmental control capabilities. Taking into account your specific loading dock, traffic flow, and requirement for insulation and weather stripping. Choose the best design from an elite manufacturer of loading dock equipment.

What are the benefits of pit-mounted dock levelers and installing them in a pit?

Pit-mounted dock levelers deliver a flush, low-profile installation that presents a tidy deck appearance when not in use and integrates seamlessly with the other loading dock equipment. When a pit is installed, the deck is able to rest flush with the dock floor. Which improves safety and aesthetics while making it easier to use integrated accessories such as laminated bumpers and insulation. Weather stripping, along with proper structural steel support. Is critical to successful hydraulic operation, as well as the longevity and efficiency of the dock leveler.

How do edge-of-dock levelers differ from a mount or pit-mounted dock leveler?

Dock levelers sit at the edge of the dock and are a cost-effective solution for low-weight-range workload situations. And do not need a dock pit. On the other hand, dock levelers that do need a pit are recessed at the floor level and are more appropriate for a high weight range and more regular usage. The more heavy-duty options. Edge of dock levelers are more basic and simple, but pit-mounted and hydraulic also have more levels of advancement. Like powered elevation, lip hydraulic extensions, and other compatibilities to hydraulic pump and motor units.

What maintenance does a hydraulic leveler need to stay the safest loading dock choice?

Hydraulic levelers need a more involved maintenance process. Like checking pump and motor stations, checking for hose and cylinder leaks, checking fluid levels in hydraulic systems, checking that the activation systems are working properly. And checking that the deck surfaces are in good condition and not too worn out. A good rule of thumb is to always do regular maintenance of the manufacturer of the dock equipment and maintain the harbor with regular observations. Keeping it well-maintained means that the leveler will be working well and smoothly for a longer period of time.

Can hydraulic dock levelers improve productivity and safety at busy loading docks?

Yes, hydraulic dock levelers improve productivity because they help reduce loading and unloading time by allowing fast and consistent push-button cycles. These hydraulic dock levelers help make sure. That the lip of the dock leveler extends and that the hydraulic deck of the leveler descends and rests on the trailer. which reduces accidents and stall downtime. Hydraulic dock levelers are the best choice for loading docks wanting to focus on productivity. And safety because of the hydraulic technology that makes the transitions smoother and requires less manual labor.

What accessories and options are available for loading dock levelers to enhance insulation and environmental control?

Loading dock levelers also have accessories, such as weather stripping, insulated dock seals, to laminated bumpers and side guards. That help improve energy efficiency and environmental control. Load dock equipment manufacturers offer insulated pit skirts, full perimeter weather stripping, and dock shelters to minimize air getting in. These accessories help maintain steady internal temperatures, reduce energy loss. And maintain a controlled internal and external environment for sensitive goods.

Reference Sources

- Oregon State University Repository: Centrifuge modeling of the seismic performance of pile supported wharves on sloping rockfill

- Humboldt State University Digital Commons: Safety Evaluation Report for Humboldt Bay Independent Spent Fuel Storage Installation

- Lehigh University Institutional Repository: Capacity of Vertical and Inclined Plates Embedded in Beach Sand

- CDC Stacks: Incident Report on Dock Plate Safety