Quick and efficient workflows keep a warehouse running smoothly. During loading and unloading processes, safety becomes even more crucial. One of the first pieces of equipment that keeps safety a primary concern is hydraulic loading dock levelers. This equipment keeps the gaps between the trucks and dock platforms so that goods can quickly flow through. This article will answer the most frequently asked questions about hydraulic dock levelers and how they increase the safety and operational efficiency of a warehouse compared to other dock levelers. This guide was created to help warehouse managers and operational leaders understand the advantages and safety features that highly functional hydraulic levelers offer in the workplace.

What Is a Hydraulic Loading Dock Leveler?

A hydraulic loading dock leveler is a tool used to connect a loading dock to a trailer to make the loading and unloading of products easier. Unlike other dock levelers that require workers to put in physical effort to level the dock and trailer, hydraulic dock levelers use a hydraulic system that lifts the dock to the correct level and height. This system makes quick and easy level adjustments and ensures that the trailer is docked correctly, improving the safety of workers and the workplace.

Employees using the hydraulic dock levelers have full control of them and can lift and lower them whenever they choose. They can also handle extremely heavy products, which is ideal for warehouses and distribution centers. Newer dock levelers also have safety switches that automatically safe the dock leveler in a safe position, emergency stop switches, and they are built with strong materials to make them last a long time. Hydraulic dock levelers make the loading and unloading of products easier and also provide a safe and modern workplace for employees.

Definition and Core Functionality

An integral part of any loading dock is the hydraulic loading dock leveler. It is the bridge that allows the efficient transfer of products from one area to another. What is more, hydraulic systems offer more efficiency, dependability, and ease of use as compared to other systems. Here is a breakdown of some of the functions and amenities of hydraulic loading dock levelers.

Adjustable Heights

Hydraulic dock levelers can accommodate several different heights and can be adjusted to fit truck beds. Providing a solid and level surface while loading and unloading.

Built-In Safety Features

A number of safety features protect users from leveling and docking accidents while the levelers are in operation. Features of the levelers include resting in a safe position, an emergency stop, and safety lip barriers.

High Load Capacity

Heavy-duty, high-efficiency hydraulic dock levelers are made for intense and high-capacity use for loads that weigh anywhere from twenty thousand to fifty thousand pounds.

Durability

The hydraulic dock levelers are made from high-grade materials and can withstand a variety of harsh weather conditions, giving the levelers long-lasting dependability.

Easy Use

The manual operations of loading and unloading the levelers are minimal as the hydraulic controls feature simple push-button systems for raising and lowering the platform, improving efficiency and saving on labor costs.

How Hydraulic Levelers Work Compared to Mechanical and Air-Powered Models

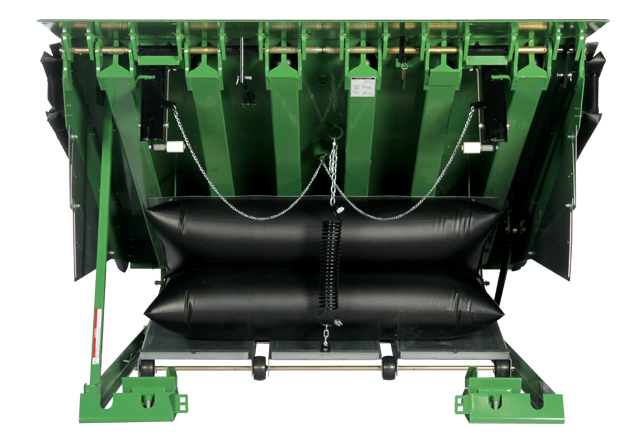

Hydraulic dock levelers function using a fluid-based piston and cylinder system to lift and lower the platform. The system uses a pump and an electric motor to pump hydraulic fluid into the cylinders. Because of this, the hydraulic system has granular control. Even with heavy loads, the levelers will lift with no problem. When it comes to heavy loads and durable applications, the hydraulic system will outperform the competitors. With no chains or pulleys that the operators have to control, hydraulic systems outperform the mechanical options. Because of this, smoother operations are completed with decreased user fatigue.

On the contrary, air-powered dock levelers use a bellow or airbag system to lift the platform. Due to fewer moving parts, they have less maintenance, but might also have a lower lifting capacity. Because of this lower lifting capacity, they also might not have the same precision. These systems are also more prone to damage if there are sharp objects around that can pierce the airbag.

All in all, for more demanding applications and modern warehouses, the maintenance, load capacity, and user requirements of hydraulic levelers outperform the rest. They are also very durable, which will make them last longer and be more cost-effective.

Key Features and Advantages of Hydraulic Loading Dock Levelers

Effortless Operation and Increased Productivity

The purpose of hydraulic loading dock levelers is to improve productivity in the workplace. By pressing the button, the levelers raise and lower automatically to fill the space between the dock and the truck trailer, which eliminates the need to do it by hand. This operation makes loading and unloading much quicker, which leaves more time for employees to do other work.

In addition, modern hydraulic dock levelers come with other features, such as transition technology. This technology reduces the bumps and vibrations in the operation to protect the workers and the equipment. Additional safety features, such as auto lip extension and auto return to dock, further improve safety. This seamless operation also reduces downtimes for the levelers, which makes them very valuable for busy warehouses and logistics.

Enhanced Safety for Workers and Goods

Hydraulic Loading dock levelers are designed to ensure the safety of workers and freight while loading and unloading. The Safety of workers and freight presently is of the highest priority for facility owners. The levelers are designed to stop and secure the freight safely to the loading dock to ensure that uncommanded hydraulic drops do not occur. Safety of workers is of the highest priority, and dock levelers are equipped with non-slip surfaces, side containment to secure the freight, and prevent workers from falling off the levelers. Communication of loading and unloading is important. Levelers do have warning systems of lights and sounds that help workers and control operators to perform their tasks while maintaining a safe working environment. Today, with many of the safety systems and features dock levelers are designed with, the systems still comply with safety in the warehousing and logistics.

Heavy-Duty Performance and High Load Capacity

Hydraulic loading dock levelers are adaptable to the needs of vendors and logistics, and supply chain service providers. Having a heavy-duty steel body and fully welded steel reinforcements, loading dock levelers are built to withstand the usage of equipment with load parameters being as high as 30,000 – 50,000 lbs and rising. The dock levelers are made to accommodate equipment made to handle heavy shipments and a wide assortment of inventory.

The smooth flow of the system through advanced hydraulics helps the movement of the equipment both to the dock and to the trailer. Performance and operational safety are enhanced with safety equipment like a telescopic lip and an auto-return dock safety feature. Heavy use, high capacity, and good standards of operational safety make hydraulic loading docks the go-to levelers for anywhere that needs high-level productivity.

Reduced Manual Labor and Ergonomic Benefits

With the use of hydraulic loading dock levelers, manual labor is reduced, and the loading and unloading process is streamlined, resulting in a reduced strain on the workers’ bodies. The levelers have automated features such as push-button height adjustments, which removes the time-consuming labor of adjusting the levelers. The advanced automation improves ergonomics as the workers no longer have poor body mechanics. Resulting in a reduced risk of injuries from workplace injuries of the overuse syndrome (e.g., carpal tunnel syndrome, back aches from lifting, etc.). Modern hydraulic dock levelers have progressive speed control, which increases the safety and comfort of the operators. With these dock levelers, operators will have the best level of comfort and safety as well as the best level of operational efficiency. They will easily become the most important dock levelers in the industry.

Types of Hydraulic Loading Dock Levelers

Standard Hydraulic Dock Levelers

Standard hydraulic dock levelers are designed to be dependable and efficient when bridging gaps in loading docks and transport vehicles. The engineering of smooth and effortless raising and lowering of ramps and aisles is done with hydraulic systems. The strength and durability of used materials allow for withstanding heavy usage and frequent availability of systems, making it ideal for high usage dock environments.

Modern hydraulic docks’ standard levelers come with additional features like push buttons, and hydraulic dock levelers are push-button activated for smoother controls. Greater control is achieved, and auxiliary work for employees and dock operators is diminished. The levelers are versatile with regard to types of vehicles and weights of loads. Storage facilities, distribution, and production of goods are serviced with these devices. To enhance protection in alignment and loading while lowering slips, devices come with anti-slip materials and extended lips.

The levelers provide a balance of efficiency and technology safety, and are a great addition for any company that is looking to get dock levelers for their docks. The dock levelers are one of the principles of modern material systems and are used in almost every company in the world.

Vertical and Edge-of-Dock Hydraulic Levelers

Vertical and edge-of-dock hydraulic levelers are designed to improve safety and efficiency in the loading docks of various industries. Vertical hydraulic dock levelers are best suited for temperature-sensitive storage applications or deployments where security needs to be enhanced. Such as in food storage or in the cold chain. Vertical levelers will completely seal when in the stored position, which prevents excess energy loss and safeguards against unauthorized entry or contamination. This model will withstand a variety of heavy loading conditions and is very sturdy.

Conversely, edge-of-dock levelers tend to be less expensive and are a good option for an installation at a facility with less severe loading requirements or minimal pit construction. These levelers mount directly to the dock face and provide a level surface without any gap to the trailer. That helps with easier loading and unloading. They are very reliable and require little maintenance, which is why edge-of-dock levelers are a good option for small distribution centers and warehouse operations.

Both vertical and edge-of-dock hydraulic levelers use the best hydraulic technology for improved performance. These models use intelligent sensors and automated systems to improve the safety and efficiency of operations. These supervision technologies allow meeting the diverse demands of safety and efficiency of different industries, from retail to manufacturing. These models strike a balance between the safety, space-saving, and cost efficiency needs of modern dock systems and offer a technological solution.

Custom and Specialty Solutions

Every custom dock leveler is designed to meet unique operational challenges and individual industry demands. Such configurations eclipse average dock levelers, which provide flexibility to adapt to unusual dock changes and to a wider variety of operational configurations. An example is a vertical storing dock leveler, which is ideal for facilities that need clean and/or cold storage levelers. Other levelers need to be extra-wide or long for large vehicles or large materials. In particular, demanding applications benefit from advanced powered levelers, whether hydraulic or air. Automotive, food and beverage, and pharmaceutical industries enjoy optimized efficiency and custom safety from such advanced technologies. Seamless integration to modern supply chain operations is achieved through innovative technologies such as custom programmable automation, IoT-enabled sensors, and, of course, custom dock levelers. Workflow productivity is enhanced by such systems. They solve operational demands while offering long-term cost reductions.

Materials and Construction

Reinforced Steel and Durable Components

Hydraulic loading docks are built with reinforced steel frames and high-tensile platforms to withstand heavy use and harsh working conditions. Their heavy-duty hinges and superior welds provide strong resistance to wear, corrosion, and chemical exposure. Modern designs use robotic welding for greater precision and reliability. This robust construction ensures hydraulic dock levelers can handle high traffic and heavy loads daily with consistent performance.

Corrosion Resistance and Weatherproofing

Hydraulic loading dock levelers are built with tough conditions in mind, and corrosion-resistant coatings are essential to how these machines operate and how long they last. These devices are finished with powder coating, galvanized steel, and other rust preventative coatings to protect fully from moisture, salt, and other corrosives that will degrade materials. Also, durable seals, drainage systems, and other protective weatherproofing keep vital parts of the leveler working rain or shine, blizzards or heat waves.

Most hydraulic dock levelers today are equipped with better materials and treatments, such as epoxy coatings, that make these machines better performing and able to absorb the dock weathering caused by spills and extreme rusting. Also, to better withstand the elements, more and more heightened protective weatherproofing epoxy steel hydraulic parts with polymers are used, along with more stainless steel frames and extra structural parts. All of these features and treatments will make your loading dock accessories and levelers last longer, operate more operating, self-sufficient, and weatherproof in waterfront and open aviation right industrial working environments.

Advanced Sealing and Insulation Options

Hydraulic loading dock levelers are created with the most flexible and durable seals. These seals can withstand years of temperature fluctuations while being compressed and expanded. Weather seals help control the temperature inside your building, keep the heat inside when needed, and prevent the loss of your climate-controlled air, saving you lots of money.

Levelers are now built with foamed decks and thermal insulation, so levels of heat and cold get trapped inside, meaning your energy loss is kept to a minimum. These are especially handy if you are working with temperature-sensitive goods. Once all of these advanced seals and insulation are integrated into the levelers. They can save you energy as well as money.

Applications of Hydraulic Loading Dock Levelers

Warehouses and Distribution Centers

Hydraulic loading dock levelers are essential for the daily operations of warehouses and distribution centers worldwide. They ensure efficient, safe, and timely loading and unloading for all types of goods, from perishables to heavy equipment. With push-button control and rapid-response features, hydraulic dock levelers improve worker safety, streamline handling, and support the fast-paced demands of modern logistics.

Manufacturing and Industrial Facilities

Hydraulic loading dock levelers help streamline the loading and unloading processes for manufacturing and industrial facilities. These levelers are designed to serve the gap in height between dock platforms and the majority of truck beds. Modern hydraulic levelers have custom features like auto activation, push-button controls, and workplace safety features to mitigate the dangers of workplace injuries and operator mistakes. These levelers are built for extreme precision and durability, making them very economical for the construction of industrial facilities.

Systems like these are built for seamless and uninterrupted flows of work, making them very effective in places where there are lots of production-related workflows and quotas to meet. They help to reduce operational downtime and improve the efficiency of the entire logistics workflow. Also, hydraulic dock levelers can adjust to any truck, load, and weight container, which allows them to meet customer requests. Organizations looking to improve productivity and increase safety standards are good candidates to purchase hydraulic loading dock levelers.

Cold Storage and Food Logistics

Hydraulic dock levelers are very important in cold storage and food logistics because they allow temperature-sensitive products to be loaded and unloaded without breaking the cold chain. They are designed to ensure the cold chain is maintained and limit temperature fluctuations that may pose a risk to perishable products. They can make fine adjustments to the height, so they are able to be used in even the most difficult conditions, making them the safest loading dock choice. They can make adjustments to make a level bridge to the warehouse and the truck. They also help slow the loss of energy and help prevent food loss due to temperature change. They even prevent the food from being exposed to outside air. These levelers are the most important products in the cold food logistics industry because of how much they value food safety.

Retail and E-commerce Fulfillment

Retail and e-commerce fulfillment relies on hydraulic dock levelers providing the seamless loading and unloading levelers of the distribution centers due to the rapid growth of online shopping. These levelers allow the smooth flow of products between docked delivery vehicles and distribution centers to eliminate the risk of damage and handle products more efficiently. Modern levelers have control safety features like advanced control systems and anti-slip surfaces that allow safe and automatic operation of lip extensions. These levelers also integrate into smart warehouse systems to maintain optimum productivity. Closing the gap between vehicles and storage areas makes hydraulic dock levelers vital to the fast-paced needs of retail and e-commerce.

Installation and Maintenance

Professional Installation Best Practices

To guarantee durability, safety, and peak efficiency, a hydraulic loading dock leveler must be installed properly. Here are professional installation tips that make a good practice guide:

Site Assessment and Preparation

Conduct an initial site evaluation and check that the dock area meets the requirements for the leveler.

Confirm that the pit dimensions have been measured properly to ensure compatibility with the dock leveler model being used.

Removing debris and ensuring a stable, level surface at the site will be needed.

Make Sure of Proper Anchoring and Alignment

Make sure that the dock leveler is properly aligned to the pit, based on the specification provided by the manufacturer.

Firmly secure the equipment by using strong anchoring systems to ensure that there will be no movement during operational activities.

Electrical and Hydraulic Connections

Confirm that safety codes and standards for the electrical wiring and hydraulics of the electric hydraulic dock leveler have been followed.

To ensure correct installation and functionality, certified professionals should be the ones to implement and test the control panel.

Testing and Calibration

Under the leveler, conduct realistic load test scenarios to ensure that its components are operational.

Sufficiently calibrate the hydraulic system to avoid malfunctioning of the extension and retraction functions at the lip.

Training and Documentation

Make sure operational training is provided for staff so that safe equipment usage becomes possible.

To assist with maintenance, repairs, and warranty service in the future, training manuals and maintenance documents should be distributed.

Ensuring safe and effective operations and cutting potential outages and expensive repairs is the goal of these best practices.

Routine Maintenance, Troubleshooting, and Repairs

If you want your hydraulic loading dock levelers to function smoothly, safely, and last for a long time, you need to put in some proper care and attention. In this article, we give a clearer outline of what you need to do to perform routine maintenance, troubleshooting, and repairs:

Check hydraulic fluid levels

We recommend doing the checks every 3 months or so. It is good not to let the level drop too low, or you will start to experience some malfunctions in the equipment or start to wear things out faster.

Lubricate the moving parts of the hydraulic dock leveler to ensure smooth operation during loading and unloading operations.

Every month, put on some high-quality grease on the pivot points and the hinges. This will help smooth out the operation so that things move more easily.

Before you add the new grease, wipe the area with a cloth to avoid any buildup of grease or dust.

Check for leaks

Every week, you should perform some inspections. Check the hoses and fittings to see if there is hydraulic fluid leaking out of any of the systems.

If you find that any of the components are leaking or need to be replaced, do this immediately to avoid any sort of pressure loss or a potential leak of damaging fluids.

Test dock leveler alignment

You should ensure that the dock level is always properly aligned to the bed of the trailer during operation.

If you notice that the dock level is out of alignment, you will need to make some adjustments and do some repairs on it. This will help you keep everyone safe and will avoid damaging your pallets of goods.

Examine the safety features

Every 3 months, it is good to check that the safety stops, toe guards, and locking systems are all working properly.

If you find that any of the features are broken or worn out, make sure to replace them so that you keep the loading dock leveler legal and safe to operate.

By incorporating these steps, people can reduce unscheduled failures and increase the longevity of hydraulic loading dock levelers.

Cost Considerations and Long-Term ROI

In terms of gaining a profit from a hydraulic loading dock leveler, thinking of first costs and ROI (return on investment) is crucial. When it comes to ROI, the following five factors are the most important to analyze:

Initial Installation

The value of custom hydraulic dock levelers and their installation is costly. Levelers cost between five to and fifteen thousand dollars, depending on the leveler’s size and specifications. While the value of a professional installer costs a little more than others, their services are worth the expense because of the value of their professional service, keeping the levels safe and optimal.

Maintenance

Operational longevity requires frequent maintenance of hydraulic levelers, like inspection of parts, replacing hydraulic fluid, and lubrication. Depending on how much the levelers are used, maintenance costs about five hundred to one thousand dollars each year.

Energy Efficient

The more modern hydraulic leveler systems are more energy efficient than older mechanical systems. Spending on the energy-efficient systems is easily compensated, as you save money on yearly operational costs, as the systems save 20 to 30 percent of operational energy costs.

Minimal Repair & Dowtime

A high-quality dock leveler means no unplanned breakdowns or emergency repairs. Because they are operationally efficient, you will save thousands of dollars in operational downtime each year.

Asset Longevity

If well-maintained, hydraulic dock levelers last a minimum of 15-20 years. This long lifespan decreases the need for replacements, increasing ROI in the long run by spreading costs over a longer lifespan of the product.

By considering these points, companies will be able to fully utilize the financial benefits of having a hydraulic loading dock leveler, while also ensuring productivity and efficiency savings.

Safety Features and Regulatory Compliance

Safety Lips, Emergency Stops, and Guard Rails

Dock levelers with hydraulic systems include various customizations to add an extra level of safety for employees and materials to keep everyone and everything safe. Safety lips are designed to keep forklifts and other pieces of machinery from driving off the edge of the dock abs automatically nose to the dock for proper seal alignment.

Guess how many emergency stop buttons are on levelers? That’s right, everyone. Might need to stop for safety if the dock leveler’s emergency stop is pressed. Let the models with emergency stop controls on the side of the leveler be your go-to for complete control of safety in the workplace.

The internationally recognized and accepted governing body of the USA safety standards is OSHA, and with more than enough safety to be compliant with operational safety and dock efficiency enhancements. Safety guards a high high-visibility safety standards and protective to minimize the risk of falling safety protective equipment around hydraulic and manual dock levelers.

Compliance with OSHA and Industry Standards

Hydraulic loading dock levelers have been made to conform to and even surpass the guidelines stated by the Occupational Safety and Health Administration (OSHA). Compliance with OSHA makes sure workplace hazards and their associated risks are kept to an absolute minimum. OSHA standards govern loading dock equipment and levelers to protect workers from fall-related risks and other hazards associated with levelers, including disengagement, equipment failures, and ergonomic stress injuries. Examples of safety features dock levelers should have are anti-slip, toe guards, and adequate warning signage.

Moreover, even though OSHA guidelines should be adhered to, every industry also has its own specialized guidelines, which are outlined in the ANSI MH30.1. These give guidelines on the levelers, their design, and safety and functionality. The guidelines ensure that the levelers can efficiently and safely perform in various operational conditions with heavy loads and repetitive usage to maintain fully operational safety functionality.

Contemporary hydraulic loading dock levelers also have automatic safety stop features, warning systems, and safety ergonomic designs, which further promote dock leveler safety and operational efficiency. These levelers are made using durable materials and advanced engineering to ensure OSHA and other industry-wide standards are met reliably and efficiently. These improved measures also environmentally sustain the work dock and promote the safety of the work environment.

Innovations and Smart Technology in Hydraulic Loading Dock Levelers

Automation, Push-Button Controls, and IoT Integration

The warehousing and logistics sector has transformed due to the incorporation of automation, push-button controls, and IoT (Internet of Things) technology in hydraulic loading dock levelers. The processes wherein levelers are automatically operated highly decrease the manual functions required, and much less room is left for human error. The ability of operators to immediately use a push button to release and position dock levelers provides the needed agility to allow for a more seamless loading and unloading. In complicated dock environments, the aggregate time and effort to operate is often the defining factor. With technology, significant time is saved, and the operations are streamlined more than ever.

The advanced technology in dock levelers does not stop there. It is enhanced with IoT functionality, which provides essential real-time monitoring and data collection. The embedded smart sensors in the machine can track usage patterns, determine when there is a problem, and signal to the operators or members of the maintenance team to take action before the issue becomes serious. Quantum improvements can be made in working efficiency with long-term equipment usage due to this approach, termed predictive maintenance, which minimizes downtime. In addition, IoT-enabled systems can be integrated with multifunctional distributed systems to allow remote supervision of multiple loading docks for enhanced control and streamlined workflow. Such Hydraulic loading dock levelers are now essential for modern, highly integrated, and digitized facilities.

Predictive Maintenance and Remote Monitoring

Dock leveler maintenance and management have changed to a more efficient way of being completed, thanks to predictive maintenance and remote monitoring. Utilizing advanced IoT sensors and data analytics, malfunctioning equipment can be repaired before failures that cost more in the long run. Maintenance can always able to be completed more proactively during times when real-time data is able to be taken. Real-time data is able to be monitored for hydraulic pressure and temperature, as well as cycles turned to ensure maintenance is completed when the leveler needs it and not when it has been scheduled arbitrarily.

Remote monitoring has also provided facility managers the ability to manage and oversee maintenance of several different docks and, therefore, several different levelers all at the same time using a centralized dashboard. Real-time data monitors the levelers and will send alerts and notifications before a failure to ensure maintenance can be completed during downtime of the leveler to minimize loss of productivity. Remote monitoring that works in tandem with predictive maintenance keeps breaks in the equipment to a minimum. It also makes the equipment last longer, lowers the cost of running the docks, and makes the working environment within the docks safer, especially during loading and unloading operations. Facilities using this technology have to be able to run their system to a high level of efficiency and with a great deal of reliability.

Energy-Efficient and Sustainable Design

Dock Levelers should be Hydraulically Operated and Eco-Friendly. Due to the Eco-Friendly initiatives becoming very important in designing modern Dock Levelers and their Operating systems, adjusting to Eco-Friendly operational etiquette and playing their part in being Eco-Friendly have become vital goals. Responsive Eco-Friendly Hydraulics are integrated into modern dock Levelers. These Hydraulics are self-sufficient in energy and are designed to give Optimal Responsive Performance while consuming minimal amounts of energy to give Superior Responsiveness. In maintaining high operational Performance, modern Dock Levelers with Eco Hydraulic technology are designed to operate at even lower electricity consumption.

There is also eco-friendly Stainless Steel and coatings technology to give Eco-friendly Steel and reduce contamination of the environment. Adjustable hydraulic flow, standby modes are Eco-Friendly hydraulic systems technology to conserve energy while they are not operational at active tasks.

Recent Innovations are aimed at closing thermal gaps, making a Dock Leveler fit securely to a trailer’s Dock to minimize energy loss. Closing the gaps reduces the energy needed to heat and cool the facility, a goal of modern eco-friendly facilities. Hydraulic Dock Levelers are designed to promote productivity while also being eco-friendly, a goal of modern technology and hydraulic design is state of the art.

Comparing Hydraulic Loading Dock Levelers to Other Leveler Types

Hydraulic vs. Mechanical and Air-Powered Levelers

Hydraulic dock levelers offer superior automation, durability, and safety for heavy-duty use, while air-powered levelers are cost-effective and environmentally friendly for lighter applications, and mechanical levelers are budget-friendly but labor-intensive.

Tabular Summary:

| Parameter | Hydraulic | Air-Powered | Mechanical |

| Operation | Automatic | Semi-automatic | Manual |

| Durability | High | Moderate | Moderate |

| Safety | High | Moderate | Low |

| Efficiency | High | Moderate | Low |

| Cost | High upfront | Low upfront | Lowest upfront |

| Maintenance | Low | Moderate | High |

| Installation | Complex | Simple | Simple |

| Eco-Friend | Moderate | High | Low |

| Load Capacity | High | Medium | Low |

| Use Case | Heavy-duty | Light-duty | Occasional |

Choosing the Best Solution for Your Facility

Choosing the right dock leveler for your facility is necessary to ensure the dock leveler is the right fit for efficiency, safety, and cost effectiveness in the long run. If you plan on getting your dock leveler system, keep the following factors and information in mind:

Operation

Automatic: This is the best and most effective option for larger facilities. It’s the most simple to work with and is the best and most seamless option for a high-volume loading/unloading dock facility.

Semi-Automatic: This option is the best fit for a moderately sized facility. It’s a good balance system between fully automated and entirely manual dock levelers.

Manual: This is the cheapest and most cost-effective option; however, it is also the most labor-intensive and is not the best option for facilities with high usage of the dock levelers.

Durability

Automatic: This is the most durable of the three options and can handle continuous use of heavy-duty loads.

Semi-Automatic: This option has a lower durability than fully automatic and will work best in low-to-moderate level usage situations.

Manual: This option also has lower durability and is best used on more infrequent use conditions, plus only for lighter loads.

Safety

Automatic: This option is the safest of the three and has the highest safety rating.

Semi-Automatic: This safety level for this option is the most moderate of the three and is fully manual and up to the operator.

Manual: This option has the most manual labor and is, therefore, the least safe of the three.

Efficiency

Automatic: For this option, you will have the highest speed and the most efficient level of operations.

Semi-Automatic: For this option, you will get moderate efficiency with balanced speed of operations and manual adjustments.

Manual: This option is the least efficient and will have the slowest speed of operation.

Cost

Auto: High initial investment, but saves more in the long run in terms of efficiency, durability, and easy maintenance.

Semi-auto: Not as expensive an investment, making it a more budget-friendly option in the middle.

Manual: Offers the lowest initial cost, making it best for smaller operations and tighter budgets.

Consider the specific needs, operational constraints, and budget limits of your facility in order to choose the best option for the dock leveler.

Market Trends and Future Outlook

Growth in Automated Loading Dock Solutions

There’s a growing demand for automated loading dock systems and technology due to advancements in retail and warehouse operations. Modern hydraulic dock levelers are becoming integrated with automation systems for seamless loading and unloading. These levelers have remote access and monitoring with robust safety features like auto-positioning and fault-appropriate safety controls.

According to industry analyses, the need for speed concerning the flow of goods in supply chain systems and increased activities in e-commerce will drive the adoption of automated hydraulic dock levelers. Self-leveling systems and motors; energy, gas, and resource-saving systems; and IoT innovations will automate processes in work systems and improve efficiency. Wear and tear-related maintenance of mechanized items. And the devices will also improve, further enhancing the hydraulic innovations, improving dock systems.

Competition for facilities in operational technology improvement is increasing. And so are the advantages of automated hydraulic systems. Raw square footage and access to facilities are disappearing, so logistics operational systems will need to become more automated.

Leading Brands and Recent Product Innovations

Nordock Inc

Key Innovation: TeleDock series with a patented telescoping lip design for versatility and safety.

Notable Data: Decreases wear and damage by 20% more than traditional lip designs, making it ideal for high usage dock applications.

Sustainability Focus: Motors use 15% less energy than standard designs.

Blue Giant

Key Innovation: U-Series Leveler that integrates a hydraulic safety barrier.

Notable Data: Can accommodate a substantial load of 50,000 lbs.

Sustainability Focus: Contain biodegradable hydraulic fluid to limit environmental damage, aligning with modern hydraulic design is state of the art.

Rite-Hite

Key Innovation: Hydraulic Dok-Lok system interlock enhancements.

Notable Data: Exceeds the standard of dock to truck alignment by a margin of 30%.

Sustainability Focus: Eco-Mode to save energy by using less while on standby.

Pentalift Equipment Corporation

Key Innovation: HD Hydraulic Series deployment that is fully automated and push-button activated.

Notable Data: Compared to manual systems, it is 25% more efficient and faster.

Sustainability Focus: 40% of the materials used in the system are recycled.

Serco

Key Innovation: HDS Series that includes patented hydraulic circuit technology.

Notable Data: Operates with a substantial load of 60,000 lbs.

Sustainability Focus: 50% of fluid leaks are decreased by advanced sealing technology.

These top brands keep changing the field with the innovations they have made to fit the needs of today’s logistics and keep incorporating eco-friendliness and efficiency in operations.

SEPPES

Main Achievement: The Intelligent Load Optimization System (ILOS) makes cargo transportable.

Significant Information: Able to carry mixed-weight loads of up to 65,000 lbs.

Sustainability: Uses recyclable materials and energy-saving systems that allow for a decrease in carbon footprint by 30 %.

Out of all competitors, SEPPES most tech-advanced and focused on sustainable operational efficiency and decreased environmental footprint.

Conclusion: Selecting the Right Hydraulic Loading Dock Leveler for Your Operations

Key Considerations for Facility Managers and Owners

Considerations When Choosing A Hydraulic Dock Leveler

Hydraulic dock levelers are some of the most common dock levelers found in the country, so choosing one that fits the needs of the operation is critical. Here are some of the most important factors to consider.

Weight Capacity

What is the typical weight range of the loads that will be using the dock leveler? Hydraulic Dock levelers have a capacity range of 25,000 lbs to 80,000 lbs, so determining this will help align operational needs to available products in the market to prevent underperformance and damage to the equipment.

Dock Traffic and Environment

What is the operational frequency of the dock, and what type of vehicles are using the dock? Docks that are really busy with high traffic and a mix of different vehicle types will probably need a heavy-duty leveler that will be able to withstand the constant operation.

Energy Use and Battery Efficiency

For power systems that have modular low-power hydraulic pumps and battery systems that are designed to use low power. Those should be prioritized to help achieve an operational energy efficiency while decreasing operating costs. Some models achieve a 20% energy reduction while also increasing battery systems’ operational efficiency, which will contribute to a more sustainable operation.

Safety Features

Automatic lip extension, anti-slip surfaces, and emergency stop features are common in hydraulic dock levelers. These safety features prevent accidents and downtime. Possible warning features include visual and auditory alarms to alert users of improper dock use or a dock hazard. While completing warning systems, safety innovations will make the workplace more efficient.

Durability and Longevity

Durability can also impact how hydraulic dock levelers are structured. Dock levelers that will get heavy use and will be subject to extreme conditions should be made of high-quality, corrosion-resistant material. With dock levelers that are corrosion-resistant, a dock leveler’s lifespan can be extended to withstand consistent use over several years.

Final Recommendations for Safety, Efficiency, and Value

When deciding what hydraulic loading dock leveler is best, consider a few things, I suggest. First, I consider safety systems. Workers should have all the safety protections, such as fail-safe systems and systems that help load and unload goods safely. I also consider systems that help save energy. These systems cost less money to operate, and they improve the efficiency of the systems. The best levelers are made of strong materials that will last through daily use. When installing the dock leveler, have professionals from a leading manufacturer of loading docks to guarantee the leveler will last. Also, get professional service to help maintain the leveler. Some systems meet all the criteria that would provide the best long-term efficiency and value.

Frequently Asked Questions (FAQs)

What are the benefits of electric hydraulic dock levelers for a quality loading dock?

Electric hydraulic docking levelers are perfect for busy dock regions because they provide fully powered rise and lower hydraulic operations. Industry-leading docking equipment manufacturers note that electric hydraulic docking levelers are easily push-button activated and reduce operator effort compared to pull-chain systems. Levelers also have features where the lip automatically extends or can have powered extension functions with hydraulic cylinders to rest securely on the trailer. They are often the safest and most reliable choice for docks that need to accommodate a wide variety of sizes and levels of equipment because they help prevent damage to equipment and provide uniform capacities.

How do pit-mounted dock levelers compare to vertical storing dock levelers?

Recessed dock levelers sit in a holding pit and can go up and down to the dock level. Once the leveler fits over the trailer, the dock can go down to the trailer and be used to load and unload the trailer. Once the load has been changed, the dock resets to the flush position. Vertical storing dock levelers store the deck vertically when not in use, opening up the pit. This provides greater security and weather control. Vertical storing levelers are designed to include laminated bumpers and bumpers that act as protection for the dock and the trailers. The choice between a vertical storing leveler and another design depends on the position of the dock, the space available for pit construction, and the over-arching desired dock equipment for over 60 daily operations. Either design can be used for a hydraulic leveler or an electric hydraulic system.

Are edge of dock levelers suitable alternatives to traditional hydraulic leveler systems?

Edge of dock levelers are less complicated than the rest of the dock levelers and are most often used when there is no pit available. These compact units sit at the end of a dock and are less complicated to install than a full dock leveler. They can be electric, hydraulic, or mechanical. But also may have a limited lip extension and lesser capacity than the full dock levelers. For a dock leveler designed for heavy-duty use, a hydraulic dock leveler is most frequently used. This is especially true for those dock areas where heavy use is expected. A hydraulic dock leveler also offers greater structural support and additional functions, which the hydraulic control cylinders are used to complete.

What maintenance does a hydraulic dock leveler require to remain a safe, reliable choice?

Checking if there are leaks in the hydraulic pump, as well as checking in on the motor stations, fluid levels, hoses, seals, laminated bumpers, and bumper hardware, needs to be part of the inspection routine. Make sure to check if the push button the docks are equipped with is functional and that the lip is able to retract and extend automatically when needed. Every month, and after the docks have been used heavily, it is imperative to check the structural steel welds and the condition of the dock plates. Regular check-ups and maintenance on the hydraulic systems used on the dock levelers, and maintaining the design of the hydraulic systems with preventative maintenance, ensure there is no damage and proper functioning of the docks, especially in high-demand areas.

How do electric hydraulic dock levelers operate during loading and unloading?

A dock leveler that is electric and hydraulic has an electric hydraulic pump and a motor, along with other components in the leveler that are used to lift the dock. The dock leveler has a lip that is able to extend and rest on the trailer that is loaded because of the hydraulic functions. The dock levelers have a simple push of a button to raise and lower, and they have fully powered cycles. In addition to the push button functionality, there may also be an airbag to help maintain the desired position on the dock and to secure the leveler in position, making the docking process safer.

What product specifications should I consider when choosing a hydraulic leveler?

Some key product specifications include capacity ratings (available in uniform capacities), deck size (available in different sizes and capacities), lip length and extension capability, hydraulic pump and motor station ratings, structural steel construction. And whether the units are pit-mounted dock levelers or vertical storing. Other considerations should include bumper type (laminated bumpers are common), dock plate, compatibility, and controls (push-button electric, hydraulic, or mechanical). For optimal performance, ensure specifications match your dock position, trailer types, and expected throughput (volume of items processed in a given time).

Can hydraulic dock levelers prevent equipment damage and improve safety?

Yes. A properly specified hydraulic dock leveler minimizes the gaps and height differentials between the dock and trailer. That also minimizes tip-overs and product damage. Automatic lip extension, controlled hydraulic descents to allow the deck to smooth rest, strong bumpers, construction of steel. And safety of personnel and equipment are the safest loading dock options. Electric hydraulic dock levelers are ideal in high usage dock areas for a controlled and repeatable operation, which protects personnel and equipment.

What options exist for retrofitting older docks to modern hydraulic designs?

Retrofitting can include replacing mechanical dock levelers with electric hydraulic systems, adding stations for hydraulic pumps and motors, upgrading to vertical storing or pit-mounted dock levelers as applicable. And adding laminated or new bumpers to give trailer and dock protection. A review of ASSESSMENT LOADING DOCK by an expert manufacturer of loading dock equipment offers recommendations for product specifications, range of uniform capacities. And an air bag or another safety upgrade that could be needed to make the hydraulic design state-of-the-art and suited for high-volume use dock operations.

Reference Sources

- CDC (Centers for Disease Control and Prevention): A report discussing safety mechanisms and incidents involving hydraulic dock levelers. Link to source

- EPA (Environmental Protection Agency): A document detailing hydraulic systems in construction and loading operations. Link to source

- University of Minnesota (Ageconsearch): A paper on transportation productivity, including loading dock operations. Link to source