Loading docks are important parts of every active warehouse or distribution center. These docks help your warehouse link your stored goods with your transport vehicles. With all the goods coming in and out of the warehouse and all the workflows, it is important to keep the warehouse energy efficiency, safe, and temperate; that is where insulated dock doors come into play. These doors are more than entrances. They raise the energy efficiency of the warehouse, keep the goods safe, and help workflows run more efficiently. This guide will help you understand everything you will need to know about insulated dock doors, going over all the key benefits to insulate doors, and how insulated doors improve your dock operations. Get ready to uncover all the insights you will need to make the right dock door decisions.

What Are Sectional Insulated Dock Doors?

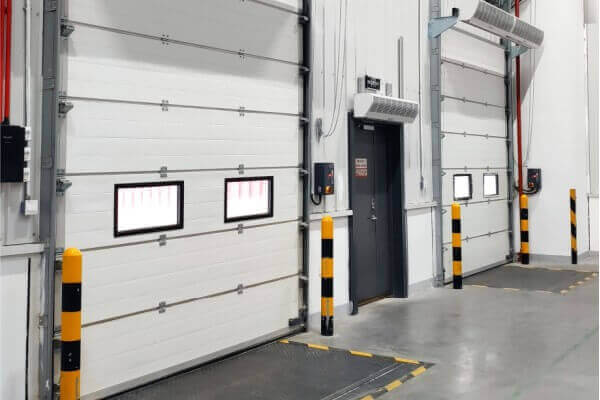

Sectional insulated dock doors are specialized for loading dock areas for better insulation and toughness. They consist of hinged panels that allow the doors to open and close vertically, saving space and enabling rapid function. The energy-efficient door is insulated to keep the temperature steady, saving energy and protecting the products inside from the outside elements. They are designed to withstand a great deal of use for better security and to improve the function of the loading dock.

Definition of a Sectional Overhead Door

A high performance sectional overhead door is an efficient and versatile door system found primarily in commercial, industrial, and loading dock locations. Made of several fortified panels hinged together, the door operates in a vertical motion on a track system and slides to a resting position just beneath the ceiling. Steel or aluminum is commonly used to make the doors, and insulation could also be installed to increase energy savings through thermal efficiency and to aid in keeping the door operations safe for temperature-sensitive materials.

The convenience and safety of sectional overhead doors have also modernized with the addition of remote controls, smart sensors, and auto-openers. Sections of overhead doors are designed to be as space-saving as possible to be the perfect solution for buildings with very little clearance. Other modern upgrades of sectional overhead doors focus on improving the Security, Durability, and Noise levels (SDN) to handle high levels of traffic and to sustain use over the years. Sectional overhead doors combine modernization with practical use, and their popularity in improving the efficiency of operations and loading workstations is clear, especially in commercial garage doors.

Key Features of Insulated Models

Ultimate Thermal Performance

The insulated models of these doors are built with top-tier materials that possess excellent thermal insulation to help control indoor temperatures while also cutting expenses.

Excellent Quality of Construction

These doors are made with weather-tough materials for double-skinned steel or aluminum that has an insulated construction. This gives a building with these doors a weather-tough performance that lasts.

Reduced Noise Complaints

The insulated models are optimally insulated to sound quiet from outside to make a more peaceful working environment.

Improved Safety and Security

These models include a stronger locking mechanism that goes a long way on give stronger security from unauthorized people getting in.

Flexible Design

These doors are also made to suit the look and measurements of all buildings, coming in a variety of sizes to fit with the intended colored end and arrangement finishing touches, while also providing the needed functionality.

Material Types and Insulation Ratings

Customers of insulated dock doors have many options available to them concerning door materials and insulation ratings. Customers should choose the insulated dock doors best suited to their unique needs. Below are five of the most common materials used and their insulation ratings.

Steel with Polyurethane Core

Insulation- R Value: Up to R-17

Summary: This option has the best insulation and is the most durable. It is best suited for facilities that need to protect their interiors and are looking for maximum energy efficiency.

Aluminum with Insulated Panels

Insulation- R Value: R-12 to R-15

Summary: This option is light and strong and has insulated panels; it is good for mid energy efficiency and is best suited for facilities that need moderate corrosion resistance.

Fiberglass Reinforced Plastic (FRP)

Insulation- R Value: R-7 to R-10

Summary: This option is moisture and chemical-resistant and is commonly used in facilities that have very harsh environmental conditions.

Wood with Foam Insulation

Insulation- R Value: R-8 to R-12

Summary: This option is best designed for facilities that want to keep the traditional exterior and want to save energy by putting in more efficient insulation.

Galvanized Steel with Polystyrene Core

Insulation- R Value: R-10 to R-14

Summary: This option has good corrosion resistance with strong thermal insulation and is best for facilities that need good insulation without sacrificing exposed exterior durability.

Facility Managers can decide what materials work best for their specific operational and ecological needs, and each of these materials has these unique advantages.

Common Applications for Sectional Insulated Dock Doors

Benefits of Insulated Dock Doors

Energy Efficiency

Having insulated dock doors gives you great thermal resistance. When rated, these steel sectional overhead doors average R-10 to R-14. With the great thermal resistance, you can keep the inside temperature stable and help reduce energy losses. This leads to the building saving money on heating and cooling.

Temperature Control

This type of door is perfect and the only option for businesses that manage temperature-sensitive products like food storage and pharmaceuticals. The insulation prevents the temperature from fluctuating to keep the products inside defrosted.

Durability and Longevity

Built for heavy use, insulated dock doors have rough textures and corrosion-resistant surfaces to withstand big swings in weather and wear. This ensures that these doors last a long time, so building owners don’t have to put down money for maintenance often.

Noise Reduction

The insulation also helps keep noise from getting in. This is especially useful for keeping the working space comfortable when you are in a busy industrial area.

Enhanced Security

The added insulation gives the dock doors extra strength and prevents unauthorized people from getting inside. This will keep the facility’s valuable stored goods protected.

Impact on Energy Efficiency and Cost Savings

Dock doors that are insulated and sectioned offer significant energy efficiency and cost savings for businesses. Several commercial and industrial establishments have reported benefitting from insulated dock doors for soft-seal energy savings. The design is enhanced for energy efficiency, with insulation to prevent heat transfer and interior temperatures from fluctuating. This is especially useful for controlled temp environments like cold storage and warehouses. These doors prevent energy loss and decrease heating and cooling costs.

Recent studies have shown insulated dock doors to be an energy-efficient building design. Insulated dock doors have energy-measuring plugins to state that businesses using insulated dock doors have energy use savings. Facilities using high performance sectional insulated dock doors realize cost savings with efficiency and sustained operations. Business insulated dock doors are a key industrial ability for energy effectiveness from ave business perspective.

Noise Reduction and Environmental Control

Sectional insulated dock doors are ideal for reducing noise and controlling the environment, which makes them a great asset to Industrial and Commercial Facilities. These dock doors, which include advanced insulation, don’t just block noise; they create a much quieter working environment by blocking outside noise. With that located in busy urban areas or near highways, it can cause noise pollution that disrupts operations and decreases productivity.

On top of that, these doors help control and protect the internal temperature by acting as a strong shield to outside elements. These doors also help control the air inside by stopping the movement of outside air, which also stops the movement of dust, debris, and other pollutants. Because of this, the air that the employees breathe is cleaner, and the area overall is more comfortable, especially for the employees who are working. TOGETHER, the high-grade sealing technologies, sectional dock doors provide a very good answer to businesses that value employee health, noise mitigation, and the environment.

Comparing Sectional Insulated Dock Door Options

Overview of Product Variations

Business knows that when it comes to sectional insulated dock doors, there are numerous types to choose from, and each business can customize a sectional insulated dock door to their specifications to fit their business’s industry. For example, style insulated steel doors are a rather popular choice due to their structural integrity and thermal resistance, and are great for projects when the temperature must be kept controlled in a specific range. For example, aluminum sectional doors are a great substitute. They are great corrosion-resistant doors that are great for high humidity or high exposure to the outside elements, and are often preferred in these situations due to their aesthetics and lightweight, but retain structural integrity.

Another example is speed-insulated doors. They are great for projects that deal with a lot of traffic in a warehouse, distribution center, or manufacturing facility. They seal doors when they are closed to retain temperatures, and use materials to keep temperatures in a controlled range.

Businesses can customize the panel thickness, track style, and window arrangement to fit their needs. Advanced tech with integrated monitors, robotics, and additional safety measures is available today to fit your needs.

Making the right choice from available options allows businesses to maximize productivity, lower energy consumption, and provide durability for tough industrial situations. If the emphasis is on looks, quick operation, or better insulation, there is a multi-purpose sectional insulated dock door that gives varied options.

Product Highlights and R-Value Ratings

Section insulated dock doors are built for any kind of industry and offer great performance for your business’s needs. High-performance steel and aluminum panels filled with polyurethane and polystyrene, along with great insulative qualities. These doors are weather-durable and smooth for any kind of use. These are great for any business, like a warehouse, distribution center, or manufacturing business.

When you are buying a dock door, understanding the R-value is very valuable. R-value is the thermal resistance measurement unit, so understanding whether you need higher or lower insulation is important for your business to save on future energy costs. There is a model of sectional insulated dock doors with an R-value of 10 to 26, saving your business money on energy expenses and making your space more temperature consistent throughout the changing seasons. Every type of door is a balance of energy saving and adapting to the environment of your company.

Choosing Between Steel and Aluminum Models

There are a lot of things to take into account when looking at steel and aluminum sectional insulated dock doors and their polystyrene insulation. For instance, the specific needs of the facility should really be at the top of the list. Steel doors are famous for their strength and durability, as well as their heavy-duty performance and wear and tear resistance. Because of this, they are often more inexpensive at the start and can be very beneficial for busy industrial workplaces since they’re very resistant to damage, such as dents and impacts.

However, steel sectional overhead doors are heavier. Aluminum doors have a lightweight construction and are resistant to corrosion. Because of this, they are more desirable for coastal or high-humidity regions. There is more flexibility when it comes to their design as well. They often have the modern appearance that many facilities are looking for, can have larger or more windows, and are more popular than their steel counterpart for this reason.

All in all, especially when operational and environmental needs are taken into account, the choice really comes down to the aesthetics of the facility. The more you understand the advantages and disadvantages of the material, the more performance and energy efficiency value you can obtain from this investment.

Key Considerations When Selecting a Dock Door

Facility Requirements and Climate Control

In doughnut-shaped insulated sectional doors, temperature control is critical, especially in places with extreme heat or frost, because the insulated thermal doors are the only mechanisms that assist in retaining the heat or cool climate you have cultivated within your temperature-sensitive building. This temperature-sensitive building needs insulated section doors with a high R-value. Insulating R-value measures walls, ceilings, and other aspects of the building. Doors that help contain temperature are needed in your temperature-sensitive building, and because heat-sensitive buildings include refrigerated warehouses or food service buildings, the necessity of high R-value insulative doors is critical.

Climate control is a critical element that no other insulated section door can provide a high level of control without, and climate control is in need of proper sealing and weather stripping that assist in controlling other environmental aspects, such as the wind, rain, and snow.

The more these aspects match your daily business goals the more you can save in operational costs. With all these, other environmental and temperature control features embody a need to know the insulated section door is understand the critical nature of climate control doors.

Balancing Costs and Long-Term Savings

When selecting sectional insulated dock doors, buyers should consider not only the initial purchase price but also long-term cost savings. Although high-quality insulated dock doors cost more upfront, their superior insulation, weather sealing, and durable construction significantly reduce heating, cooling, repair, and maintenance expenses over the door’s service life. This longevity lowers the overall total cost of ownership.

Beyond maintenance savings, businesses may also benefit from energy rebates, incentives, and operational efficiency gains. Industry experts note that well-designed insulated dock doors deliver strong returns through energy savings, reduced downtime, and improved sustainability. A strategic purchasing decision should always factor in long-term financial and environmental benefits, not just the upfront cost.

Maintenance Tips for Longevity

Taking care of sectional insulated dock doors will help them work better and last longer. Here is how to keep them working their best:

Inspect Regularly: Look for things like torn panels, broken seals, and loose bolts and screws. This will help to avoid minor issues turning into more expensive problems.

Keep Parts Lubricated: Regularly lubricate the hinges, rollers, and tracks. If the doors are moving smoothly, the components are going to be under less stress and work better for longer.

Keep Seals Clean: Seals will wear down with dirt and debris buildup. Make sure the seals are clean and in good condition so the dock doors will keep their insulating ability and help avoid energy waste.

Tighten Hardware: The door features and bolts will loosen up with everyday use. To keep things working right, every so often, check every piece of hardware and make sure things are tight.

Balance Test and Spring Checks: If the door is heavy and the springs are weak, the door is going to cause problems for the whole system. Make sure the energy-efficient door is working properly, and the springs are in good condition, or hire someone to make sure things are working in a safe and efficient manner.

Protect Weather: For doors that take on rough environmental conditions, make sure anti-rust protection is effective. Shield the surface with resistant coatings, and look for damaged insulation and replace it as necessary.

These maintenance practices ensure the sectional insulated dock door works as intended, minimizes energy expenditure, and enhances sustainable use. Always follow the recommendations provided by the vendors to tailor suggestions to the specific model of door you own.

Industry-Specific Applications

Cold Storage and Food Facilities

Ensuring precise temperature control and energy efficiency in cold storage and food facilities is the role of Sectional insulated dock doors. These doors are designed to leave no thermal leakage while protecting temperature-sensitive items like perishable foods, beers, and other pharmaceuticals. New sectional insulated dock doors are designed with the most advanced temperature-resistant insulation (R-values) of polyurethane or polystyrene cores, precisely manufactured panels, and electronic seals that control energy compliance while increasing the bottom line. Several designs include corrosion-resistant and hardy other insulation to better control the temperature in the harshest and most frequently used elements, which is vital for the temperature and cleanliness maintenance industries.

Warehousing and Manufacturing Facilities

Sectional insulated dock doors are critical to streamlining operations in warehouses and manufacturing plants. These doors maintain insulated internal temperatures to keep products from spoiling, and less energy is used to heat or cool the building. Because these doors are made with polyurethane foam cores and galvanized steel, they are built to last and will suffer less wear and tear over the years.

A sectional insulated dock also saves time and improves productivity. These doors have smooth and reliable openings that allow for rapid entry and exit. Many doors on the market also have weather shields, are wind resistant, and are also noise reducing. These are all excellent qualities for a highly industrial building. For current warehousing and manufacturing needs, these doors are built to protect against unsafe air quality and contamination while also keeping temperature zones stable.

Automotive and High-Performance Needs

Industries like automotive and manufacturing need specially designed dock doors that are insulated and energy efficient at the same time. Temperature control and energy saving are huge factors in these industries. Insulated dock doors are designed to control the indoor climate and energy loss within a facility while maintaining the interior at a consistent temperature. Temperature-sensitive items are kept safe and protected.

These types of doors are created with state-of-the-art materials that provide the best insulation, such as polyurethane and polystyrene. These doors are also designed with high-impact impact durable materials that add to the longevity of the door. Automotive dealerships and manufacturing companies have the greatest need for dock doors that are functional and energy-saving because of the high vehicle and parts turnover.

Insulated dock doors are made with the most modern technologies, like automated opening and closing features and advanced weatherproofing. These doors are designed for smooth performance, increased safety, and maximum control. Doors of this caliber are a must-have with high-energy turnover industries like automotive stores and manufacturing companies. End of the line with these doors is gaining control and productivity with better energy performance.

Real-World Best Practices

Replacement Tips for Upgrading Dock Doors

Planning the replacement of dock doors can make a difference when it comes to the efficiency of the installation and the long-term benefits. Here are 5 tips to help you make a seamless transition in replacement.

Assess Current Door Performance

Determine how the dock doors are performing and how long they have been there. Are there any operational issues, and are they functioning at a sufficient rate? Frost and oxidation can slow the doors down, and losses can be incurred. Some more recent studies have shown how replacing dock doors can save up to 25% energy losses in temperature-controlled facilities.

Choose the Right Material

Consider what purpose the facility doors will serve and the duty level. Do you need steel hard doors, or do you need more flexible and lightweight insulated panels? Insulated dock doors can save 20%- 30% in heating and cooling costs.

Measure Accurately

Make sure the doorway measurements are correct in order to avoid more issues during the installation. Perfect-fitting overhead sectional doors are equally as important as the right operational clearance and dock dimensions.

Prioritize Safety Features

Be sure to choose doors with enhanced important safety features. Safety in the workplace is important, and doors with photo eye safety features and emergency door safety release features, and compliance with workplace safety standards, are required.

Think About Efficiency and Automation First

Think about the prospect of buying automated dock doors that have quicker cycles for opening and closing. This can enhance effectiveness and lower downtime, especially in places where there is a high demand for speed. Automation can lift productivity in active zones by 15%.

Considering the above recommendations gives businesses a strong footing in ensuring the seamless transition that captures all the benefits that come with dock door replacement.

Strategies for Maximizing Energy Efficiency

Improving energy efficiency on sectional insulated dock doors is a combination of different solutions and best practices working together. Some of these include:

Superior Insulation Material

Use doors with improved thermal resistance (R-value) ratings and insulation technology to include foam-injected panel doors or other energy-efficient materials. Designs such as these retain heat and keep internal temperatures within a desired range.

Close Gaps

Check doors regularly for gaps, cracks, or worn seals that can create air leakage. Using quality weatherstripping and closing seals on all sides of a door can minimize energy loss.

Use Smart Control Systems

Automatic or smart control systems for dock doors can ensure they remain open as briefly as possible. Using sensors and control systems (PLCs), energy loss during door opening and closing can be minimized.

Perform Regular Maintenance

Maintaining dock door systems includes inspections and loosening of door hinges, opening systems, and weather seals. Poor maintenance can severely impact the thermal performance of dock doors, increasing energy costs.

Add LED Light

Use energy-efficient LED light systems for the areas around dock doors. LED lighting is effective for detailed work (loading and unloading), and unlike other systems, it performs at a lower energy use.

Use Solar Energy

If possible, use things like door automation systems powered by solar panels. This strategy works hand in hand with energy-efficient design dock doors and decreases the facility’s carbon footprint.

Companies may look to incorporate more strategies like these to increase the energy efficiency in their insulated dock doors and therefore, lower the operational costs and green the facility more.

Performance Optimization Techniques

Using advanced optimization strategies helps increase the performance of sectional insulated dock doors. These doors help improve the thermal efficiency of operational productivity, lower the cost of energy, and increase overall efficiency. Here are optimization strategies for performance improvement:

Routine Maintenance and Inspections

Routine maintenance helps ensure operational performance of the dock doors, including seals, panels, and tracks. Inspections can identify potential wear, tear, or insulation gaps so repairs can be made quickly to avoid energy loss.

Performance Sealing Systems

Well-installed and good-quality sealing systems are invaluable for reducing air leakage. Long-lasting flexible gaskets, weather seals, and bottom seals help improve thermal efficiency.

Smart Sensors Integration

Automated and precise operational dock doors equipped with smart sensors make for efficient openings and closings of the door to reduce energy loss.

Advanced Insulating Materials

Modern sectional dock doors can be equipped with new variations of insulating materials offered for sale on the market, including polyurethane foam, which helps control radiant energy transfer and replaces insulating materials with lower thermal resistance (R-values).

Installation of High-Speed Door Mechanisms

High-speed door systems limit the time doors remain fully open whilst loading and unloading. This further reduces heated-cool air exchanges and keeps the environment controlled within the building.

Weatherized Performance Enhancements

Additional features like heated tracks, frost-resistant seals, and strengthened door panels may help keep performance at the desired level and maintain operational efficiency during extreme weather.

Use of Data Analytics and Monitoring Systems

Data monitoring systems can help facility operators determine energy consumption and energy consumption patterns. Changes can be made to doors in order to optimize energy saving and the performance of the door.

Using the described performance optimization strategies, businesses can ensure that their overhead sectional doors open and close at the maximum level of energy efficiency. This results in a reduction of energy consumption, lower energy costs, and better operational efficiency.

Conclusion

Recap of the Value of Quality Dock Doors

There are many benefits to getting insulated dock doors, especially if they are sectional and high-quality. To maximize value and efficiency for the business, here are five benefits to consider getting insulated sectional dock doors for your business.

Energy Efficiency Improvement

When it comes to thermal insulation doors, they will be able to keep the interior space at a constant temperature. Because of this, energy used to heat and cool the space is considerably less, and energy bills will be lowered. Studies show the heat loss of doors is reduced by 40%.

Increased Longevity and Durability

With insulated dock doors, the doors are designed to withstand bad weather, constant use, and wear and tear. Because of the solid construction, there are fewer repairs to be expected.

Operational Efficiency Improvement

Sectional dock doors are designed to open and close reliably. This is important for fast unloading and loading times. This will cut downtime and improve the total cost of ownership.

Enhanced Security

When it comes to protected and stored equipment and inventory, insulated dock doors provide sturdiness and extra security.

Noise Increase

If the dock doors are insulated, there will be noise reduction. This is important if your building is in a heavily populated or loud area.

The advantages that come from features make sectional insulated dock doors an important asset for companies for saving energy and further operational and overall expenses.

Call to Action for Evaluating Existing Doors

For those who feel uncertain about their sectional insulated dock doors’ condition, or how well they function, step away from them for a moment and think about their condition. Are they providing the value your company seeks in energy savings, noise control, and security? If the answer is no, then possibly time to think about replacing or upgrading. Contact me so we can guide you in the right direction.

Frequently Asked Questions (FAQs)

Sectional door: What are sectional insulated dock doors, and how do they differ from rolling steel?

Insulated sectional dock doors are overhead doors made of horizontal slats aligned together that are able to roll up along a track. Each slat is usually filled with insulation, such as polyurethane or fiberglass, that aids in thermal protection. While other doors, such as rolling steel doors, are made with a single panel of metal that rolls and unrolls, sectional steel doors are able to be customized to a greater extent. These doors are designed to have a higher thermal efficiency to save on heating and cooling costs, a greater sealing capacity to keep debris and bugs out, and a flexible horizontal section door design. Many commercial and residential models are made with galvanized hot-dipped steel or metal that is woodgrained and embossed. These models are made with a concrete side and are designed for commercial use or for use in a residential garage with an interior.

Loading docks: What door configuration is best for loading dock doors in moderate to severe environments?

If heavy-duty steel sectional doors or high-performance insulated sectional doors need to be installed, it is most likely due to the loading dock environment’s site conditions. These steel sectional doors have 2″ thick insulation to be thermally effective. Other components that such doors have are reinforced stiles, extruded aluminum, and each door is tested against wind-loading conditions ranging from light to heavy. The factors to consider for selection include door size, expected traffic, and whether hot or cold air is on the other side of the overhead sectional doors. Due to low maintenance and high design efficiency performance, many facilities choose the insulated steel doors or the energy series.

Doors designed: How do insulated sectional doors provide thermal efficient protection?

Insulated sectional doors protect against heat loss by utilizing advanced materials like polyurethane insulation or layers of insulated glass. These materials work to ensure minimum heat loss between an indoor area and its outdoors. The design of sectional overhead doors along with insulated steel panels and thermally efficient seals, works to ensure minimal energy loss and draft for efficient operational doors. Utility costs from heating or cooling the facility or building will be reduced. Optimum thermal efficiency will be achieved with an appropriate combination of extruded aluminum thermal breaks, lower R-value materials, and other thermal protection augmentations to the design.

Sectional overhead doors design: What hardware features and maintenance are typical for commercial sectional door systems?

Commercial sectional door systems include heavy-duty components like rollers and torsion springs, direct drive operators, reinforced stiles and hinges, and optional emergency service kits. Mounting hardware is hot-dipped galvanized or coated to meet any wind loading and other design sustainability requirements. The doors are low maintenance when well specified and will perform properly, and heavy-duty steel sectional doors will experience the best service life, while also requiring inspection, lubrication of the door and hinges, and prompt availability to worn hardware. Emergency maintenance service available for worn-out components.

Loading dock doors: Are insulated sectional overhead doors suitable for commercial door and garage doors applications?

Yes, insulated sectional overhead doors have become pretty common in commercial applications such as sectional garage doors, overhead doors for warehouse loading docks, retail stores, etc. Insulated sectional garage doors offer a high degree of thermal efficiency and can be insulated steel doors and woodgrain embossed finishes as a decorative option, and multiple door styles to suit high traffic and Energy Series performance. The doors can have medium to high-performance specialized hardware features.

Commercial door: How do steel sectional doors meet wind load requirements and impactable conditions?

Steel sectional doors are designed for wind loads by utilizing reinforced sectional steel panels and stiles, heavier gauge steel such as 20 or 24, as well as bracing. For impactable conditions, high-performance or heavy-duty steel doors have stronger stiles, impact-resistant hardware, and reinforced tracks. Correct door and hardware selection and installation ensure the doors will withstand moderate to severe wind and incidental impacts while retaining thermal and security performance.

Insulated steel: What finish and material options are available for insulated steel doors?

Insulated steel doors are available options such as stucco, woodgrain, or smooth embossed steel, as well as woodgrain embossed or plain exterior steel. They are made of hot-dipped galvanized steel due to its durability and effective corrosion resistance. They can also have interior polyurethane insulation or insulated glass vision panels. There are also differing thicknesses to choose from, such as 24 or 20-gauge, as well as options of extruded aluminum or steel to achieve harmony between the look, sturdiness, and energy-saving capabilities of the door.

Energy series: How energy-efficient are insulated sectional doors, and what factors affect their thermal efficiency?

These energy-insulated steel doors, which are often sold as an energy series, are one of the best options for thermal efficiency. With their doors being 2 inches or thicker, having thermally efficient seals, and overall good door design, doors that minimize air movement can keep doors warmer or cooler on either side. The thermal efficiency of your door can also depend on its size and any glass panels it may have, as well as the quality of the hinges, how it is hung, and, of course, how well it is sealed. If your building needs to stay particularly hot or cold, picking an insulated steel door that offers good thermal protection will allow the building to use heating and cooling less often and stay warm and cool more comfortably.

Reference Sources

- SECTION 08 30 00 – SPECIALTY DOORS AND FRAMES

View PDF

This document discusses specifications for aluminum and insulated galvanized steel sectional doors. - Loading Dock Design Guide

View PDF

Covers the importance of insulated doors for weather protection and worker comfort in loading docks. - Section 08 10 00 – Doors, Frames, and Hardware

View PDF

Provides details on insulated steel overhead doors for loading docks, including air curtain compatibility. - Volume 1 – Design Guidelines & Technical Sections

View PDF

Discusses insulated doors with internal stiffeners for structural integrity at loading docks. - Design Guidelines & Performance Standards

View PDF

Specifies insulated overhead sectional steel doors with a minimum R-value of 17.