As part of any well-run distribution center or warehouse, safe material handling and organized logistics begin with the loading dock. During the loading and unloading of trucks, dock levelers perform the critical function of bridging the gap between the trailer and the dock. In this article, learn the importance of dock levelers for the operational efficiency of modern loading docks. Discover the attributes and the benefits of dock levelers, and how they improve safe operations and efficiency. All businesses, from small warehouses to large distribution centers, must understand the operational importance of their facilities the canto maximize throughput and minimize liability. Learn here the value of trailer dock levelers. Optimize your operations today.

What Is a Truck Dock Leveler?

A truck dock leveler is a type of loading dock equipment that fills the gap between the truck and a loading dock. It ensures that a level surface is configured for loading and unloading of items. It has the ability to adjust to the height of the truck and permit items to flow from the dock to the trailer. It increases operational efficiency and minimizes the chance of workplace accidents; hence, a truck dock leveler streamlines safety in workplace enhancements.

Definition and Core Functionality

Defining Truck Dock Levelers

Truck dock levelers are specialized equipment tasked primarily with perfecting the efficiency of loading and unloading. However, they are obligated to go about this with the utmost precaution. The following five points constitute a preliminary outline of the range of dock levelers, their function, and purpose in loading and unloading operations:

Height Adjustments

Truck dock levelers are built to bridge the gaps of any and all trucks. This makes the loading dock and the truck’s bed a seamless, collectively safe place of operation, and makes the otherwise dangerous height gaps non-existent.

Load Capacity of Heavy Duty Equipment

Dock levelers are made to withstand a variety of loads at any instance between 20,000 lbs and 80,000 lbs, depending on the model and use case.

Durability and Material

Dock levelers are usually built with heavy-duty steel to endure continuous extreme and harsh use in warehouse surroundings. Moreover, other models have specialized extra protective coatings to curb any rust and corrosion that might ensue.

Operational Mechanisms

Dock levelers can be manually operated, hydraulically powered, or air powered. This alternative gives customers cheaper alternatives that are best suited to their budget and needs.

Safety Features

A number of Truck dock levelers have various advanced safety features. This includes anti-slip surfaces, lip locks, and other safety barriers to lower any and all possible risks that might occur during operation.

Dock levelers are a prime example of tech that responds to a variety of evolving problems with unmatched efficiency, reliability, and safety on a day-to-day basis to give a tech edge on warehouse operations.

The Role of Dock Levelers in Modern Logistics

Dock levelers are critical to the efficiency and supply chain integration. They serve as a bridge between vehicles and loading docks, effortlessly facilitating the loading and unloading of goods, despite height differences. New generation dock levelers further enhance productivity by eliminating delays, decreasing manual movement of goods, and allowing faster transport of goods.

The latest designs dock levelers even integrate smart features, such as IoT (Internet of Things) sensors, which monitor dock levelers’ performance, and provide real-time information on performance, or units in need of upkeep and maintenance. These features help companies lessen downtime and enhance business operational efficiency. Dock levelers further enhance workplace safety by adding features such as automatic safety barriers, specialized anti-slip surface finishes, and sophisticated control systems for the dock leveler’s edge lip. Their reliability and versatility make them a mainstay of the logistics sector. They have enabled rapid warehouse scaling in response to demand in the sector.

Key Features and Benefits of Truck Dock Levelers

Bridging the Gap Between Truck and Dock

Truck dock levelers help in handling materials and improve the movement of goods by providing easy transition of varying height and distance of a truck bed and a loading dock in a seamless manner. Below are the features and details in helping us understand how truck dock levelers help in providing a smooth transition in the gaps.

Adjustable height Range

The versatility of different height ranges in truck beds is taken into consideration in the designs of dock levelers, such that most models providing vertical adjustment range of up to 12 inches are customizable and adaptable to a dock height. This makes it easy to load and unload trucks with different height levels.

Load Paying

Today’s levelers go with the current trend in weight capacity, which is also substantial in range. An expected docking leveler weighs between 25k lbs. to over 80k lbs. to help in sustaining the weight of freight and equipment in an industry.

Mechanical and Hydraulic Equipment

Competent performance of leveled dock systems is a factor that can be attributed to the lifting systems, which are either hydraulic or mechanical. Models with hydraulic lifts seem to be more efficient in performance along with less manual lifting and increased durability.

Slip-Resistant Surfaces

Speed and operations safety in slip-resistant platforms. Levelers in truck docks have specialized safety surfaces that are made with highly textured materials. These surfaces control the possibility of accidents that can happen when surfaces are wet or made slick.

Integrated Safety Features

Safety is one of our primary focuses during the design stage of the construction. Safety stop mechanisms, velocity fuse systems, and pop-up barriers are incorporated to avoid damage to the equipment and keep the workers safe from risks.

This equipment safely and efficiently enhances the performance of the logistics operations during the loading and unloading processes.

Enhanced Safety for Workers and Cargo

In the course of use and operation of loading and unloading procedures of the cargo, specialized equipment has been designed and developed specialized equipment with features and specifications to promote the safety of all persons and goods. Foremost of which is the employees and cargo related to the loading and unloading, and there is written and is provided with the following features, with special and additional safeguarding features to assist and promote the safety of all workers and employees. Here are the types of modern truck dock levelers and their added integrated safety features.

Hydraulic Safety Stop Systems

If there is a loss of hydraulic pressure that leads to the leveler dropping, there is a system in place to lock the leveler securely to eliminate the risk of dropping.

Non-Slip Deck Surface

The risk of slips and falls is eliminated with the use of a mat with high levels of traction and a surface that is high in durability.

Toe Guards and Side Barrier Protection

If pieces of equipment slip off the sides of the dock leveler, there is a reduction of the risk of the loss of toes due to the sides that are added with protection.

Velocity Fuse Safety Valves are essential components in ensuring the safety of hydraulic operation loading dock levelers.

If the dock leveler is moving and there is a failure, a valve is integrated with the hydraulic system that will stop the leveler from moving. This valve protects the cargo and the employees.

Automatic Return-to-Dock Position

The leveler will return to the dock position after use, and the leveler will eliminating the chance of moving, which will enhance the safety and organization of the work environment.

The built-in safety measures work together to reduce workplace accidents, protect valuable property, and make the workplace loading docks safer and more productive.

Improved Loading and Unloading Efficiency

In today’s warehouses and logistics operations, dock leveling devices stand out as a vital element that enhances the speed and efficiency of the loading and unloading processes. These devices improve productivity due to streamlined workflows and minimized downtime. Here is an explanation of five efficiency-enhancing features and benefits.

Minimized Truck Dock Times

Dock levelers offer a seamless transition from the dock to the vehicle, thereby facilitating the loading and unloading activities. As such, they help minimize docked truck turnaround times.

Increased Versatility

More sophisticated dock levelers can accommodate a greater weight range, including efficiently moving both low to high-weight-range cargoes, such as packages and heavy industrial cargo. This makes the dock levelers versatile.

Manual to Automated Systems

Systems such as hydraulics and air that are automatic improve the performance of the dock levelers significantly as opposed to manual systems.

Optimized Energy Use and Sustainability

Dock levelers have a number of features that result in reduced energy consumption, such as advanced insulation and efficient power consumption systems. This helps facilities to perform to their level best and also meet their sustainability goals.

Improved Lighting Systems

Advanced integrated systems improve the coordination and thus the speed and accuracy of the overall operations. Such systems include Control systems, alarm systems, and integrated LED Lighting.

Utilizing these components can help companies enhance their productivity and also streamline their logistics, all while cutting operational expenses.

Durability and Heavy-Duty Performance

Truck dock levelers are built to handle extremely tough industrial environments and continue to perform as expected over long periods of time. Here are five characteristics of the durability and heavy-duty capabilities of dock levelers.

High Load Capacity

Contemporary dock levelers can take on hefty loads and do so on a continuous basis. They can take on loads of 30,000 to 50,000 pounds, making them ideal for a multitude of industrial uses.

Reinforced Steel Construction

These dock levelers are constructed of high-strength steel designed to take on heavy multiple usages without showing operational wear.

Weather Resistance

Most dock levelers can handle extreme external and internal weather as a result of the rust-preserving external shielding, sealed internal corrosion, and frost-proof moisture.

Impact-Resistant Decks

Heavy machinery, such as cargo, lifts, or trolleys, can bump and grind against the dock. Therefore, dock levelers are designed to absorb the impact of damage found in compression.

Hydraulic and Mechanical Reliability

Advanced hydraulic systems and their multiple mechanical parts will enable the dock levelers to perform, without breaking, through prolonged, heavy use.

Incorporating these attributes enables the dock levelers to perform for a long time with a high operational impact, while ensuring the industrial client’s safety and high quality operational package.

Types of Truck Dock Levelers

Hydraulic Dock Levelers

Hydraulic dock levelers are built for swift movement in all loading scenarios in commercial or industrial sectors. These levelers, thanks to cutting-edge hydraulic technology, automatically adapt to the height of the truck bed, creating a safe walkway for the workers to load or unload the merchandise. They include push-button controls for ease of operation, reducing physical effort by the workers.

Contemporary hydraulic dock levelers are fitted with advanced safety systems, including emergency stops, velocity fuses, and lip keeper safety systems to improve safety. They are constructed to endure high-volume abuse in the hyper-traffic zones of the industrial world. Unlike mechanical systems, dock levelers with hydraulic systems will require a lot less maintenance, especially less than the mechanical systems, as hydraulic systems have self-cleaning features and have fewer movable components. These features and the systems and docks being in industrial/ manufacturing buildings, hydraulic levelers will boost safety and workflow for the industrial sectors.

Mechanical Dock Levelers

Mechanical dock levelers help multiple industries save money and increase efficiency when loading and unloading products. These levelers can be adjusted to the right height manually using springs and different levers to create a consistent height with the dock and the truck. They are some of the most durable and cost-efficient dock levelers available and are great dock levelers for a facility with a low budget and moderate traffic.

Mechanical dock levelers’ simplicity of design. These dock levelers do not use electrical or hydraulic designs, so there are fewer technical failures and repairs. Repairs can be very minimal and easy, therefore reducing downtime for a facility. Because of this design, however, there is a need for some maintenance. This maintenance includes things like lubrication and spring adjustments to keep the system safe and working like it’s supposed to.

Not needing power for most of the operation makes these dock levelers perfect for locations with limited power access or places that need to keep costs low. These levelers can also not require a lot of manual energy due to the improvements in design ergonomics. These dock levelers are great options for small to medium warehouses, retail backrooms, and other locations.

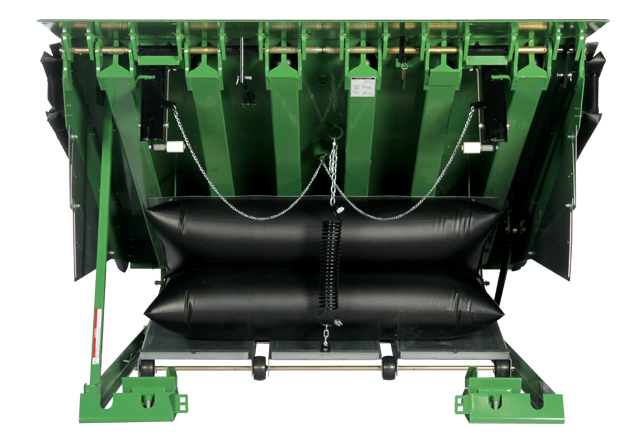

Air-Powered Dock Levelers

Air-powered dock levelers provide a unique approach to improving industrial floor systems. These loading dock levelers use mechanical or hydraulic air bags in tandem with scissor lifts to raise and position dock levelers. One of the air-powered dock levelers’ advantages is an even and smooth operation with consistent performance and highly reduced maintenance. Compared to the competition like mechanical and hydraulic levelers, the air-powered system has fewer moving parts and systems, which increases its performance and operation time.

Air-powered dock levelers provide easy, safe, and smooth operation due to their push-button activation systems and their ergonomic exhaustion of dock levelers. The design of air-powered dock levelers is eco-friendly as they substitute the hydraulic oils with an all-pneumatic lift system. Other added functions of air-powered dock levelers include automatic lip extension, fall-safe systems and custom safety systems.

Air-powered dock levelers are indestructible and reliable, which makes them perfect for high-volume and heavy-duty industrial environments like warehouses and distribution centers. They are air-powered, which makes them a highly economically sound choice.

Edge-of-Dock Levelers

Edge-of-Dock Levelers work best for sites that require light to medium-duty loading and unloading work. These dock levelers require no extensive pit work as they are mounted directly to the dock face. These levelers are economical and save space. They are designed to efficiently close the gap between dock and truck bed heights to allow for the safe moving of goods.

New edge-of-dock levelers feature ergonomic operation, heavy-duty construction designed for high-use cycles, and fully hydraulic or mechanical systems. They are best suited for loading docks with a maximum height differential of 5 inches. Nowadays, it is common for the more contemporary models to include weather seals and bumpers, which increase safety. Perfect for warehouses, retail operations, and manufacturing facilities, edge-of-dock levelers enhance the user experience with increased workflow and dependability.

Specialty and Custom Levelers

Specialty and custom levelers address specific challenges in industry material handling. Integrating specialized design features and customizations, these levelers adapt to unique dock and trailer configurations. These levelers can be modified to fit specific workflows through custom size, lifting capacity, and functionality.

Some of the innovative features of custom levelers are hydraulic or air-powered systems, advanced automation and safety locking mechanisms, and operator-friendly design. Businesses dealing with special cargo or heavy and varying loads are best suited to this equipment. A winning consideration for these equipment levelers is Special and Custom design features, rugged construction, and advanced mechanisms to safely meet the challenges of demanding levelers in loading environments.

Materials and Construction

Heavy-Gauge Steel and Reinforced Designs

Extensive testing is indicative of the performance and durability of heavy-gauge steel and reinforced construction of truck dock levelers. Made of high tensile steel, these levelers endure heavy weights, repetitive use, and extreme conditions. Even under the fused construction with substantial support struts, these levelers remain stable and rooted. New modern flexibility has, furthermore, allowed the construction of these levelers with rust-resistant coatings under galvanized finishes. This environmentally protective design allows for increased moisture and chemical exposure without accelerating the corrosion of steel. Value-engineered designs combined with advanced manufacturing sustain the design levels for longer periods, increasing safety from potential structural failures. Conclusively, these bottom-heavy gauge steel and reinforced designs assist in optimal performance and dock safety.

Corrosion Resistance and Weatherproofing

Truck dock levelers sometimes have issues caused by moisture, high/low temperatures, and exposure to chemicals. To minimize these issues, modern dock levelers are built with more corrosion-resistant and inclement-weather-proof materials. One technique used is high-quality galvanized or powder coating on the steel parts. These finishes create a barrier to oxidation and degradation.

Also, some dock levelers have water-resistant seals with heavy-duty weather stripping to mitigate water ingress and heavy rain or snow. Corrosion-resistant materials, including more stainless steel, are being used more frequently along with impact and abrasion-resistant stainless and other strong alloys. These design features, along with modern design approaches, result in dock levelers keeping their mechanical function, corrosion resistance, and structural soundness, with public safety in mind functional corrosion resistance in demanding conditions. Protective gear for the handled goods and the levelers themselves reduces overall maintenance costs.

Load Capacities and Customization

Bottom dock levelers can sustain various weights depending on which model works best for which industry. A standard model can support weights from thirty thousand to eighty thousand pounds. Heavy-duty, dock levelers can manage even greater weights. These models are perfect for warehouses and facilities working with large and heavy items. This ensures that companies can select dock levelers that suit their business operations.

Customization continues to increase in dock levelers and this allows for added functionality. Designs now come with adjustable lip lengths, hydraulic and mechanical operation, integrated safety features, and even energy-efficient options. Vertical storing dock levelers and telescopic lip levelers are helpful for certain loading situations, like limited space or specific trailer designs. Because companies can customize their dock levelers however they please, operational efficiencies are made, downtime is decreased, and safety during loading and unloading processes is improved.

Applications of Truck Dock Levelers

Warehouses and Distribution Centers

Truck dock levelers play a pivotal role in the efficient operations of warehouses and distribution centers. These facilities often handle significant volumes of goods that require smooth and safe loading and unloading processes. Dock levelers bridge the height and gap differences between loading docks and various types of vehicles, ensuring seamless material movement. With advancements such as hydraulic, air-powered, and mechanical levelers, modern designs cater to the diverse needs of high-traffic warehouses, improving turnaround times and minimizing the risk of accidents.

In addition, advanced dock levelers equipped with safety features like auto-lock mechanisms, integrated sensors, and ergonomic controls are becoming increasingly popular in these settings. These innovations not only enhance operational efficiency but also align with the growing emphasis on workplace safety standards. For large-scale distribution centers managing tight schedules and high-capacity shipments, truck dock levelers ensure the reliability and speed necessary to meet demanding supply chain requirements.

Manufacturing and Industrial Facilities

Dock levelers have an important part to play in manufacturing and industrial facilities where efficient movement of materials is vital to productivity. They close the gap between loading docks and trucks and enable smooth and safe loading and unloading. Modern dock levelers are designed to bear high loads and high frequency of use, which makes them essential in the use of heavy machines and the movement of raw and finished products.

The levelers use either aerodynamic or hydraulic systems, which makes leveling a precise action requiring very little manual effort. Additional features like energy efficiency and weather sealing prolong the life of the levelers and improve functionality. Injuries in the workplace can be mitigated, operational flow made more seamless, and the demands of the global supply chain met with the use of advanced dock levelers in manufacturing and industrial facilities.

Retail and Commercial Loading Bays

In retail and commercial loading bay operational logistics, dock levelers are crucial. They close the physical gaps left between loading bays and trucks, allowing for quick and secure loading and unloading. The dock levelers of today come with features such as push-button controls, automatic returns, and high-end accident-prevention safety features. Their sturdy constructions accommodate trucks of all heights and all weights, are vital for large variances in shipments, and are all pre-streamlined in functionality. The Integration of Technology also improves functionality with automated tracking and dock levelers made from sustainable materials. Advanced dock levelers help retail and commercial businesses improve the smooth operation of their supply chains and overall business productivity by minimizing downtime.

Cold Storage and Temperature-Controlled Logistics

In temperature-sensitive logistics, particularly in cold storage, the efficient and accurate transfer of products is essential. This process requires specialized truck dock levelers that feature insulation and robust seals to minimize temperature loss. Protected at the right temperatures, frozen foods, medicines, and other products sensitive to temperature changes are not at risk of spoiling. Advanced dock levelers automate temperature tracking and, in some cases, connect to temperature-controlled systems and infrastructure to meet strict criteria. These levels of innovation and dock functionality are what make them one of the most important elements in the logistics of cold storage-reliant industries.

Installation and Maintenance

Professional Installation Guidelines

Correct installation of truck dock levelers is key for safety, effectiveness, and longevity. Submitting professional installation guidelines also reduces future operational problems and ensures that your company will not violate compliance regulations. Below are five key guidelines that should be followed when having truck dock levelers installed.**

Conduct Inspection of the Site

Thorough inspections of the dock area should be done to evaluate structural conditions, alignment, and compatibility. Measurements should be checked to confirm that the dock leveler will fit and be able to function properly.

Confirm Proper Reinforcement

Make sure that the dock pit is adequately reinforced for the weight-bearing capacities of the dock leveler and the loads it will endure. This may require additional concrete work or additional support structures.

Verify Power Supply Connections for Hydraulic Operation

If the dock levelers are powered or hydraulic, verify that the electrical connections are up to local electrical code and that the electrical source is capable of sufficient continuous power to the system.

Leveler Alignment and Securing

For operational alignment, the dock leveler should be accurately aligned to the dock pit. It should be held motionless during operation by using the suggested anchoring methods of the manufacturer.

Perform Equipment Testing

Once Visser’s technicians have completed the installation of the dock leveler, you should test the dock leveler’s range of motion, capacity, and safety features (lip operation, stoppage, and breaks) and perform basic functioning tests to ensure the leveler is operational. Adjustments should be made for any discrepancies encountered during testing.

Systematic adherence to the protocol above guarantees that your dock leveler will function safely and to peak specifications, smoothing the operations of your logistics.

Routine Maintenance and Troubleshooting

To maximize the effectiveness of truck dock levelers regarding functionality and safety, proper maintenance and diligence are required. To serve this need, the following are listed as the top-performing maintenance actions and best practices.

Examining Hydraulic Mechanisms

Keep an eye out for and remedy the following: leaks, torn hoses, and low amounts of hydraulic fluids. When hydraulic systems are not working, there are restrictions regarding the proper and full movement of the dock leveler. Add hydraulic fluid if lacking, and replace all components that are worn out.

Moving Mechanisms should be lubricated

To all hinges, springs, and pivot points, lubricant should be applied, as this will lessen friction and prevent the mechanism from wearing out. When there is not enough lubrication, there will be excessive strain on the nautical mechanism, and the aging of the system will be accelerated.

All Features should be politely and Thoroughly Scrutinized

All safety features should be tested, such as the safety stop, as this will ensure that all are functioning as required. Failing safety features will place an excessive risk on working members and equipment lying around, and this risk should be addressed as soon as possible.

Do all fasteners feel safe to touch?

As time goes on, bolts, screws, and other fasteners will loosen due to movement and combo structures. To prevent decreased stability, impaired movement, and other maintenance issues, all fasteners should be tightened.

To ensure uninterrupted service from your loading dock levelers, check for damaged parts (deck plate, lip, bumpers, etc.) to avoid equipment damage. and quickly replace them to prevent any disruptions to overall functionality.

You can considerably reduce downtime and maximize your equipment’s service life by following these maintenance practices and troubleshooting dock levelers as issues arise.

Cost Considerations and Long-Term ROI

Purchasing a high-quality truck dock leveler is essential for any business that is dependent on efficient loading and unloading. Understanding the long-term return on investment helps justify the up-front expense for the equipment. There are five cost considerations for determining long-term ROI.

Initial Purchase Cost

The initial cash outlay for a dock leveler differs by style and specifications. Of all types of moving levelers, hydraulics are the most expensive. On the other hand, mechanical dock levelers have a higher initial cost, but lower overall maintenance costs.

Maintenance and Repair

Maintenance on a dock leveler is required for continued use and lifespan. However, maintenance costs do vary by the leveler model. Selecting equipment with high-durability components engineered with low maintenance or advanced technology will lower operational costs over time.

Energy Efficiency

Modern levelers are engineered with a focus on energy savings, especially those outfitted with insulative designs that reduce heat loss. Costly energy consumption is a common problem. Over time, utility savings can be significant.

Operational Disruption Costs

Time loss multiplier effect due to frequent operational interruptions caused by malfunctioning dock levelers is driven by increased costs associated with labor. Smooth operational workflow with little to no disruption is ensured by higher-quality models with more sophisticated engineering.

Life Expectancy and Cost of Ownership

Affordable life cycle costs associated with dock levelers with a life expectancy of 15 years or more make the overall investment cost worth it, even if the initial investment costs would be higher. Such an investment will save on ongoing replacement of components and repairs over the years.

Conclusions drawn from the indicators discussed will allow companies to optimize the selection and maintenance of dock levelers for maximum benefit.

Safety Features and Compliance

Safety Lips, Fall Protection, and Emergency Stops

Working dock levellers expose users to many workplace safety and operational efficiency issues which should be addressed immediately. Here are five workplace safety features that most modern dock levelers are equipped with:

Safety Lips

Safety lips are designed to keep forklifts, pallet jacks, and any other machine from flying off the edge of the dock.

Safety lips are usually in the up position when the dock levelers are parked, and down when in operation.

Fall Protection Systems

Fall Protection Systems promote stability in the workplace, and are made up of safety features such as lip locks and sensor-based systems that prevent the leveler from making unintended drops.

Fall Protection Systems eliminate the potential of sustaining injuries during the loading and unloading activities.

Emergency Stop Buttons

Emergency stop buttons are safety features that provide users the ability to stop or take control of the dock leveler to minimize the potential for an accident or damage to occur.

In an emergency stop, the users are granted a lot of control to avoid accidents or to minimize the damage to heavy duty loading dock levelers.

Automatic Return-to-Safe-Position Mechanism

Automatic Return-to-Safe-Position Mechanism allows the dock levelers to be inactive for a period and then enter a completely stable neutral resting position.

Automatic Return-to-Safe-Position Mechanism protects users from the risk of falling when the dock is inactive.

Hydraulic and Mechanical Safety Systems

Hydraulic and Mechanical Safety Systems ensure that the dock levelers are stable and prevent any unsafe actions from taking place when operational.

Hydraulic and Mechanical Safety Systems provide sufficient control of the dock levelers and eliminate any stimuli that might cause unsafe actions to take place during or outside of operation. When businesses equip dock levelers with safety features, they can comply with standards and create a safer workspace for all.

Compliance with OSHA and Industry Standards

Your truck dock levelers must meet the safety and efficiency standards set by OSHA and the industry. Being compliant with the standards not only assists in averting workplace accidents; it also ensures that equipment works properly. Below are five standards and regulations concerning truck dock levelers:

OSHA 1910.22 – General Requirements

States that all walking or working surfaces must be clean, dry, and free of all slip, trip, and fall hazards. This includes dock areas.

OSHA 1910.178 – Powered Industrial Trucks

There must be safe use and maintenance of powered industrial equipment, like forklifts, and there must be dock levelers that are compatible with safe use.

ANSI MH30.1-2020 – Performance and Safety Standards for Dock Leveling Devices

Describes the performance standards, testing standards, and safety standards concerning dock levelers, and these standards assist in the failure to maintain equipment and loss of integrity of equipment.

OSHA 1910.303 – Electrical Safety Requirements

There are electrical safety standards that must be adhered to concerning dock leveler systems, especially ones that are powered or hydraulic, so that there are no problematic issues with electrical safety.

NFPA 70 – National Electrical Code (NEC)

Deals with the significant issues relating to the installation and maintenance of the electrical parts of dock levelers to avoid the risk of fire or other electrical problems that may be encountered when operating dock levelers.

Complying with these standards helps businesses maintain safer and more reliable operations and keep workers from potential risks in dock areas.

Innovations and Smart Technology in Truck Dock Levelers

Push-Button Operation and Automation

Modern truck dock levelers have significantly evolved with the integration of push-button operation and advanced automation technology. Push-button controls simplify the leveling process, allowing operators to raise, lower, and position dock levelers with minimal effort and in less time, greatly improving overall efficiency. These systems often replace older mechanical or manual solutions, reducing physical strain on workers and enhancing workplace safety.

Automation takes this innovation further by incorporating smart sensors and programmable logic controllers (PLCs) to streamline operations. Smart dock levelers can automatically detect truck placement, adjust to the required height, and compensate for vehicle movement during loading or unloading. This ensures seamless alignment between the dock and the trailer bed, reducing instances of accidents or cargo damage. Additionally, some automated systems offer remote operation and monitoring, allowing facility managers to control dock levelers from a centralized system or even via mobile applications.

These advancements not only improve operational efficiency but also help businesses meet stringent safety standards and reduce downtime. With push-button operation and hydraulic operation, truck dock levelers represent a significant leap towards smarter, safer, and more productive loading and unloading operations.

IoT Connectivity and Remote Monitoring

The integration of IoT (Internet of Things) technology in truck dock levelers is revolutionizing the logistics and material handling industry. IoT-enabled dock levelers are equipped with sensors and connectivity modules that allow continuous monitoring and real-time data collection. These systems provide facility managers with detailed insights, such as the operational status of dock levelers, maintenance needs, and safety alerts, all accessible through centralized dashboards or mobile applications.

Using predictive analytics powered by IoT, businesses can identify potential issues before they escalate, ensuring minimal downtime and maximizing equipment lifespan. Remote monitoring also enhances safety by enabling automated emergency alerts if anomalies or unsafe conditions are detected. Additionally, the integration of cloud-based platforms ensures seamless data sharing across teams, optimizing coordination and boosting overall supply chain efficiency. IoT connectivity transforms traditional dock levelers into intelligent systems that support smarter, data-driven decision-making while enhancing operational agility.

Predictive Maintenance and Diagnostics

Predictive maintenance and diagnostics are revolutionizing the way truck dock levelers are managed and maintained. By leveraging advanced IoT sensors and analytics, these systems can monitor the condition of dock levelers in real-time, identifying wear and tear or potential issues before they result in costly downtime. Predictive algorithms analyze data such as hydraulic pressure, motor performance, and operational cycles to detect early warning signs of equipment failure.

This proactive approach not only extends the lifespan of dock levelers but also reduces the frequency and expense of emergency repairs. Additionally, cloud-based diagnostic tools enable facilities managers to assess performance remotely, ensuring immediate action when anomalies are flagged. Combined with automated maintenance scheduling, predictive maintenance ensures smooth and efficient operations, minimizing disruptions in high-volume supply chain environments. The integration of these technologies highlights the shift toward smarter, more adaptive logistics solutions that prioritize reliability and efficiency.

Comparing Truck Dock Levelers to Other Dock Equipment

Dock Levelers vs. Dock Plates and Dock Boards

Dock levelers are permanent, handle heavy loads, and offer high safety and efficiency, while dock plates are portable, cost-effective, and suitable for light-duty tasks; dock boards bridge the gap with higher load capacity than plates but less permanence than levelers.

Detailed Comparison Table

| Parameter | Dock Leveler | Dock Plate | Dock Board |

| Load | Heavy | Light | Medium |

| Portability | Fixed | Portable | Semi-portable |

| Cost | High | Low | Moderate |

| Safety | High | Moderate | High |

| Durability | High | Moderate | High |

| Use Case | Forklifts | Hand Trucks | Forklifts |

| Height Adj. | Wide | Narrow | Moderate |

| Material | Steel/Aluminum | Aluminum | Steel |

| Install | Complex | Simple | Moderate |

| Maintenance | Moderate | Low | Moderate |

Choosing the Right Truck Dock Leveler Solution for Your Facility

To meet the needs of your facility’s operational flow, the appropriate choice of truck dock leveler is instrumental in maximizing productivity and maintaining safety. Each choice comes down to the following key considerations:

Load capacity

What type of load and how heavy will the dock level remove it? A heavy-duty steel leveler is more appropriate if you’re in a high-capacity setting, while a lightweight, more portable leveler is appropriate for smaller, less frequent uses.

Portability

Does your facility need a fixed or a portable dock leveler? Fixed dock levelers are built right into the dock and provide dependable longevity, whereas portable or semi-portable dock levelers provide more flexibility in numerous loading and unloading tasks.

Safety Features

Safety is paramount, and modern dock levelers have safety features such as hydraulic control lips, safety lips, and emergency stop buttons to aid in mitigating accidents.

Material and Durability

What the leveler is made of is also a huge factor in how long it will last. Steel and aluminum are the most common, steel being more durable and aluminum being a lot lighter and easier to manage.

Installation and Maintenance

How complicated will the installation be? Will it be a permanent addition? Keep in mind the importance of maintenance, as it will play a key role in the overall operational downtime and expenses.

Economics of Primary and Repeat Sales

It’s important to consider cost, but it is just as important to compare that to the value of the investment and overall performance and longevity. Investing more money into a quality leveler is going to save money in the long run, because it will cost less in repairs and replacements.

If all of these factors align with your needs, you can be confident that your facility will have the best solution for your operational needs regarding a truck dock leveler.

Market Trends and Future Outlook

Growth in Automated Loading Dock Solutions

The truck dock leveler market is witnessing rapid advancements with the rise of automated loading dock solutions. These innovations are driven by increasing demands for efficiency and safety in material handling operations. Automated dock levelers equipped with advanced sensors, IoT connectivity, and programmable controls are transforming traditional docking systems into smarter and more efficient solutions. These systems not only reduce manual labor but also enhance accuracy and minimize downtime during loading and unloading processes.

With the integration of real-time monitoring and predictive maintenance capabilities, businesses can proactively address equipment issues, ultimately reducing repair costs and operational disruptions. Furthermore, the adoption of automation aligns with the growing focus on sustainability, as energy-efficient designs and optimized workflows contribute to reduced energy consumption. The rise of e-commerce and global supply chains has further accelerated the demand for such innovative solutions, making automated truck dock levelers a critical component in modern logistics and warehouse operations.

Leading Manufacturers and New Product Developments

The coop and global marketplace for automated dock levelers and other solutions for logistics has matured and evolved, thanks to many leading players’ automated dock levelers and other solutions for logistics. We have chosen the following five players, along with their product innovations:

Blue Giant Equipment Corporation

Blue Giant Equipment Corporation is a top-of-the-line company that is producing the first U-Series Hydraulic Dock Levelers, the first dock levelers with new energy-efficient hydraulic controls and advanced topless safety controls. Blue Giant is producing levelers that offer high Load capacities and velocity for demanding high-load and reliable warehouse dock levelers and warehouse environments.

Rite Hite

Rite Hite and Associates offer the RHH-4000 series dock levelers incorporating SmartDock™ technologies with the first advanced dock leveler and advanced toples in energy conservation for integrated real-time monitoring and log features that also assist integrated new technologies in performance optimization and worker safety.

Pentalift Equipment Corporation

Pentalift Equipment Corporation is well known for the HED Series Hydraulic Dock Levelers, for balanced and smooth operation, and for an excellent performance that is engineered to perfection for heavy load handling, and with new, improved weather sealing, provides total product line improvements for success in all market areas.

Serco Products

Serco Products offers an SLT Series dock leveler that is the first to incorporate interlock technology for safety, which is integrated with levelers that provide lip extension technology to accommodate a wider variety of vehicles and integrates interlock technologies for safety features for secure operation, maintenance for loading and unloading.

Kelley Entrematic

The newest product, the Vertical Stored Dock Leveler, released in 2021, minimizes dock door opening and exposure, thus providing better environmental control, better thermal control, and is more thermally efficient, highly suitable for refrigerated warehouses and logistics.

All leading manufacturers are improving their products and services, showing their commitment to modern innovation, safety, and sustainability in logistics, particularly in loading dock equipment. Safety and sustainability are industry logistics’ modern eco-business objectives.

SEPPES SEPPES has harnessed top technologies and composite materials in construction to provide customers with advanced docking levelers and extended construction life. Warehousing and logistics are SEPPES’ strongest emerging market.

Conclusion: Selecting the Best Truck Dock Leveler for Your Operations

Key Considerations for Facility Managers and Owners

Things to consider to maximize efficiency and safety, and get the most value in the long run, when buying the best truck dock leveler include the following:

Load Capacity Needs

Determine how much total weight the dock leveler will have to accommodate, including pallets, merchandise, and forklifts. In this instance, most businesses have dock levelers with a weight capacity enough to accommodate 20,000 to 40,000 lbs. However, heavy operations will require models with a weight capacity bigger than 50,000 lbs.

Type of Dock Leveler

Consider the types of dock levelers available: mechanical, hydraulic, and air powered. Hydraulic dock levelers may be best, but for small operations, mechanical levelers may be best for the budget.

Dock Leveler Safety

Ensure the dock levelers have safety features such as anti-slip surfaces and safety sensors. Safety features that allow dock levelers to return automatically to the neutral position or that include smart velocity fuses can be very beneficial for the safety of operations.

Energy Efficiency

Dock levelers that have tech features such as insulation and low, energy-efficient operating levels are best in helping reduce the impact on the environment and on your utilities long term.

Durability and Maintenance Needs

Choose dock levelers made from quality materials like reinforced steel to handle daily usage and abuse. Also, examine how each model can be maintained so that you can plan for minimal downtime and easy servicing, since this greatly impacts operational productivity.

Considering these aspects also helps facility managers and owners make the right choices so that smooth and efficient logistics activities can be carried out.

Final Recommendations for Safety and Efficiency

To ensure safety and greater levels of efficiency when selecting a truck dock leveler, a couple of details must be taken into account. First, you want to make sure the leveler is built with good construction and durable materials like reinforced steel, so that it does not get damaged with heavy and daily use. Second, you want to purchase a leveler that is also very easy to maintain so that there is less downtime and curve servicing moves from the dock leveler. Finally, the capacity and overall compatibility of the leveler must be assessed to ensure it can complement your facility’s specific operational needs. With these details, the safety of your loading dock and the overall efficiency of your logistics operations will be enhanced with the right choice of hydraulic operation dock leveler.

Frequently Asked Questions (FAQs)

What are loading dock levelers and how do they work?

Dock levelers help mitigate the gap between loading bridges and semi-trailers, creating an even transition from the trailer to the loading dock. Loading dock hydraulics raise and lower to match the height of semi-trailers for ease of loading and unloading.

How do hydraulic dock levelers operate?

Hydraulic dock levelers are equipped with a hydraulic pump that allows the deck of the dock levelers to be raised and lowered. This functionality allows for quick changes to the height of the dock, creating a smooth transition when loading and unloading different sizes and shapes of cargo. Hydraulic systems are almost always more efficient and require less manual effort than their mechanical counterparts.

What are the advantages of edge-of-dock levelers?

Edge of dock levelers are also beneficial for their compact design and ease of installation, being mounted directly to the edge of the loading dock. Additionally, edge of dock levelers help mitigate energy loss by reducing the gaps created during loading and unloading.

What is the difference between mechanical and hydraulic dock levelers?

The primary difference lies in their operation. Hydraulic dock levelers employ the use of hydraulic cylinders, while mechanical dock levelers use a pull-chain counterbalance system. Hydraulic dock levelers offer more ease of use and a smoother transition than mechanical dock levelers.

How do vertical storing dock levelers work?

Vertical storing dock levelers save dock space. They use some kind of hydraulic mechanism to move the deck up for easy access. They bring up the deck so they don’t block the loading area; this helps heighten the operational efficiency of the rig.

What safety features should I look for in loading dock levelers?

The dock levelers that you load should have some of the following. A dock ease of edge leveler that has loose safety lip extensions. A dock leveler that has a system to keep stable during the operational process. These systems help keep levelers stationary, which is important for the safety of the dock. They help ensure the safety of the workers while loading and unloading the dock.

Can loading dock levelers accommodate a variety of sizes and capacities?

There is a dock level, which means it is a miniature should do the work for you. There are extreme-duty dock levelers or light-duty work dock levelers. One should always be designed around your specific dock level requirements. There are extreme or light-duty dock levelers, and they are used a work. An extreme duty dock leveler should be designed towards your specific work around. One should always be extreme in their specific design. Working lights around; they’re specifically designed for work or extreme conditions.

How can accessories enhance the functionality of dock levelers?

Some accessories help with safing dock levelers, which include inflatable systems for added functionality which are always a nice added safety. Electronic wheel risers or pull-down operational safety systems on the dock levelers. They are a beneficial safety feature added to the dock levelers. These are dock leveler systems that have inflatable systems or wheel risers, which always help to make dock levelers have additional functionality. They are a nice added feature which are always nice added safety for systems that always have wheel risers. Safety inflatable systems have added functionality.

Reference Sources

- Massachusetts Institute of Technology (MIT) – DSpace

Level loading and cross docking in a global logistics network

This thesis explores cross-docking and leveling strategies in logistics networks. - Rochester Institute of Technology (RIT) – Repository

Incorporating Electrical Trucks and Automated Container Stacking System in the ports for sustainable and efficient operations

Discusses the integration of electrical trucks and automation in logistics. - Wayne State University – Digital Commons

Entry-level heavy truck drivers and highway safety

Examines training and safety standards for heavy truck operations. - Pennsylvania State University – ETDA

Automated Docking of a Small-scale Tractor-trailer Using an Infrastructure-based System

Focuses on automated docking systems for tractor-trailers. - US Department of Transportation – ROSA P

National Coalition on Truck Parking: Activity Report, 2015-2016

A report by the National Coalition on Truck Parking, addressing logistics and parking challenges.