Efficient loading dock operations are critical for businesses aiming to optimize productivity and maintain a safe working environment. Among the innovations transforming these vital hubs of activity, electric dock levelers stand out as a game-changer. This blog post explores how these advanced solutions enhance safety, streamline efficiency, and bring automation to the forefront of loading dock management. Whether you’re looking to reduce workplace accidents, minimize downtime, or modernize your operations, electric dock levelers offer a compelling answer. Read on to discover why these tools are quickly becoming an essential component of modern logistics and supply chain operations.

What Is an Electric Dock Leveler?

An electric dock leveler helps connect the loading dock to the truck or trailer. Electric dock levelers provide powered precision, which increases the level of safety when handling cargo. Enhanced and electric dock levelers are helpful to modern warehouses and distribution centers in terms of precise movement and streamlining workflows.

Definition and Core Functionality

An electric dock leveler functions as a vital component in logistics operations, ensuring seamless interaction between the dock and various truck or trailer heights. Its primary purpose is to create a secure environment for transferring goods, reducing labor risks, and improving operational efficiency. Below are five key features and attributes of electric dock levelers that define their core functionality:

Height Adjustability

Electric dock levelers are equipped with hydraulic or powered mechanisms that allow for precise height adjustments, accommodating trucks and trailers of varying sizes.

Load Capacity

Designed to handle heavy loads, most electric dock levelers have capacities ranging from 25,000 to 80,000 pounds, ensuring the safe movement of goods across the platform.

Push-Button Operation

A simple push-button control system offers convenience and ease of use, allowing operators to adjust the leveler quickly and efficiently with minimal training.

Safety Features

Built-in safety mechanisms, such as lip locks, hydraulic velocity fuses, and emergency stop functions, provide added security during operation, minimizing workplace accidents.

Durability and Construction

Constructed from high-strength steel with rust-resistant coatings, electric dock levelers are built to withstand harsh industrial environments, ensuring longevity and reliable performance.

These features collectively enhance performance, safety, and productivity, making electric dock levelers an essential tool in warehouse and distribution operations.

How Electric Dock Levelers Work

Electric dock levelers use hydraulic and electromechanical systems to improve the efficiency of loading and unloading to and from trucks and trailers. The primary component of a dock leveler is the electric motor, which activates the lifting mechanism to raise or lower the platform to the level of the truck or trailer. This adjustment provides a seamless transition for materials being loaded or unloaded to or from the vehicle.

Once activated, the dock leveler’s lip extends forward to close the gap between the dock and the trailer. Integrated modern systems like sensors and other controls provide for better movement and make it possible to adjust for different vehicle heights, especially in concrete recesses. Most electric dock levelers come equipped with a user interface as well as control panel safety interlocks and automatic retraction, which make use of the dock levelers easier and safer.

Electric dock levelers come with failing systems and energy efficiency components. They are reliable and help in reducing the cost of maintenance. The design and sturdy construction of an electric dock leveler enhance its operational efficiency in the supply chain and logistics. They help improve workflow in warehouses and distribution points.

Key Features and Benefits of Electric Dock Levelers

Push-Button Operation and Ease of Use

Electric dock levelers can be effortlessly operated using push-button commands, systematizing a traditionally barbaric approach. This approach also reduces employee burnout. Below are the specifics and advantages of their button-operated system:

Easy Start: Pressing a single button activates a sequence of raising, extending, and lowering, which simplifies the loading and unloading process.

Accurate Aiming: The leveler can be positioned to align with vehicles of any height to ensure safe and proper alignment.

Less Training: The simpler the system, the fewer problems new workers will have to adopt and understand the system.

Saves Time: Buttons are easier to push than performing a series of actions that are free of any form of control. Hence, dock activities and logistics can be set up faster.

Increased Protection: Lack of physical movement reduces the possibility of exhaustion, minimizing mental strain on the docks and setting provided.

Enhanced Safety Features and Operator Protection

Electric dock levelers are designed with comprehensive safety features to protect operators and ensure smooth operation in demanding environments. Below are five key safety features and their benefits:

Advanced Hydraulic Stops

Hydraulic safety stops prevent unintended descent of the dock leveler, securing it in place during loading or unloading. This reduces the risk of accidents caused by sudden leveler movement.

Lip Locks and Safety Interlocks

These systems ensure the dock leveler’s lip remains securely lodged in place during operation, preventing potential mishaps caused by a slipping or disengaged lip.

Emergency Stop Button

An easy-to-access emergency stop button allows operators to instantly halt the system, ensuring swift action during unexpected situations or malfunctions.

Non-Slip Platform Surface

Dock levelers feature a textured, non-slip surface, reducing the risk of slips and falls, especially in wet or high-traffic scenarios.

Audible and Visual Alarms

Built-in alarms provide both audible and visual indicators, alerting operators to unsafe conditions, system errors, or improper usage, enabling prompt corrective measures.

These safety features not only enhance operator protection but also optimize operational efficiency in warehouses and loading docks.

Improved Efficiency and Faster Loading Cycles

Electric dock levelers have very useful features that improve efficiency with loading and unloading time during peak hours. It enhances the overall operation and productivity during peak hours. This blog will go through five features of dock levelers that increase efficiency and loading cycles.

Push Button Operation

Manual adjustments take time and add to useless work and lower productivity. With a simple touch of a button, the entire system with the levelers increases productivity and operational work.

Automatic Leveling

Operational delays are increasing because loading is imprecise. The automatic leveling feature of these dock levelers keeps alignment with the trailer height, which increases loading precision and removes these delays.

High-Capacity Load Handling

With dock levelers that have high weight-bearing capabilities, the need for multiple trips to complete the loads is greatly reduced. The overall cycle time is improved with the use of these levelers.

Energy Efficient Motors

Using these levelers becomes very cost-effective because of the energy-efficient motors. They tend to move at a fast pace and use low amounts of energy.

Durable and Low Maintenance Design

The motors operate consistently with very little downtime. It gives the levelers reliable performance and faster loading cycles.

Reduced Manual Labor and Ergonomic Advantages

Electric dock levelers help save on labor costs and eliminate potential ergonomic hazards. With dock levelers, loading and unloading processes become more commonplace, physical labor is enhanced, and productivity is improved. The five benefits below help evince this.

Physical Strain is Mitigated

All lifting and leveling processes become automated, which subsequently slows down strain injuries occurring from lifting and repetitive motions.

Higher Productivity

With dock levelers, fewer manual processes equated to improved operations and less downtime. Certain studies indicate that levelers help enhance productivity by almost thirty percent.

Ease of Use

Ergonomic principles, which stress comfort and safety, such as ease of operation, which helps decrease the pressure on the joints and muscles, are also taken into account.

Decreased Injuries

With less manual handling, there is also less cost from injuries as these levelers help promote employee health.

Saved Time

The operation of electric dock levelers also helps enhance the efficiency of loading and unloading processes, which enables the business to schedule workloads better and offers the best flexibility to the employees.

Types of Electric Dock Levelers

Pit-Style Electric Dock Levelers

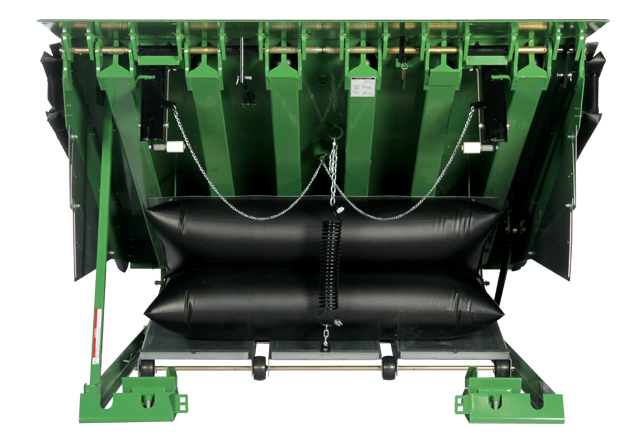

Anchor-mounted electric dock levelers bridge the gap between a docking platform and a vehicle. These levelers rudimentarily rest in a pit within the floor of the dock and overlap with the dock/surface level. Hydraulics and electric motors achieve precise and smooth movement, ensuring that the processes of loading and unloading are both efficient and safe.

Dock levelers of the modern age are complex machines. Their construction allows for the packaging of diverse industrial operations. They are truly safe machines and sophisticated levelers of the dock. In construction, these machines are steady, ensuring long construction, solid durability, and efficient operations. These machines are designed to support heavy usage and rest freely during operation. As a result, these levelers are most effective in busy centers, such as factories, distribution centers, and warehouses.

Edge-of-Dock Electric Dock Levelers

Edge-of-dock electric dock levelers are an affordable and effective option for lightweight applications and facilities with limited space. These levelers sit flush-mounted to the dock face to minimize pit construction and are electric-operated to provide rapid, unobstructed use with loading/unloading, maximizing efficiency.

State-of-the-art edge-of-dock dock levelers often have a hydraulic or mechanical electric system for improved reliability and safety. The levelers are equipped with lip extensions for improved trailer alignment, and also have mechanical striping for safety. Edge of dock electric dock levelers are the perfect choice if the trailer heights are restricted or limited. These levelers are also easy to use, which makes them perfect for retail, some industries, and loading docks. Edge-of-dock electric dock levelers are great for improved energy efficiency and are designed for long-term use without compromising reliability.

Electric Hydraulic Dock Leveler

For both commercial and industrial establishments, the electric hydraulic dock leveler is the latest technology developed to ease and maximize dock efficiency. Its performance electric operation integrated with hydraulic technology assures utmost reliability and high performance while minimizing manual work. These dock levelers have been specially constructed to handle very high weight capacities, suitable for heavy-duty work. The ease of use provided by advanced technology push-button controls, smooth platform adjustment, and remarkable integrated safety features ensures electric dock levelers provide workplace safety.

With contemporary electric hydraulic dock levelers, energy efficiency is taken to a new level with specially designed models that maximize electric efficiency while minimizing operational costs. Added features such as durability, extreme operational use, and weather seals have made these dock levelers a great addition and smart investment for both distribution and manufacturing warehouses. Not only does it maximize workflow safety, but it has also become an important factor for the supply chain and logistics operations due to the efficiency added to the workflow.

Specialty and Custom Electric Dock Levelers

Special custom electric dock levelers meet the individual challenges that make doing business virtually impossible without tailored solutions. Along with integrated control systems, exceeding legal safety requirements with safety sensors, high-visibility edges, or tailored dock levelers is a must. Other examples of custom capabilities that capture the desire of demanding industries are the ability to equip tailored models to increase the dock levelers’ custom load capacities or high with other tailored models.

Touchscreen technology, electronic motors, and other advancements of modern technology increase efficiency and optimize productivity, even at a tailored standard. Custom docks with line-integrated electronic corrosion-resistant materials or other tailored corrosion materials ensure strength and futuristic durability. These custom solutions are frameless and enhance performance and safety for workers on refrigerated docks, for food processing, or heavy manufacturing. These solutions integrate tailored technology, exceeding the safety measures of sensitive machines, or for rigorous, logistically demanding systems.

Materials and Construction of Electric Dock Levelers

Heavy-Duty Steel and Reinforced Structures

Electric dock levelers are designed using top-quality materials in order to ensure reliability in grueling work settings. Below is an extensive description of key features and vital pieces of information regarding their construction with heavy-duty steel and reinforcements.

High-Tensile Steel Components

The deck and lip are made out of high-tensile steel in order to support multiple types of loads that are regularly rated between 25,000 and 45,000 pounds, ensuring the dock levelers are able to carry heavy-duty vehicles as well as any other additional cargo.

Reinforced Framework

The base of the dock leveler contains reinforced steel beams as well as cross structures in order to provide more strength and improved resistance against deformation during use.

Anti-Corrosion Coating

The steel surfaces are treated with a powder-coated finish in order to protect against rust and corrosion, ensuring the dock levelers last a long time, even in harsh settings.

Welded Hinges and Lip Connections

Welded connections between the hinged lip and the main platform improve the overall stability of the dock levelers, increasing and reducing wear, which increases the overall smoothness of the dock levelers.

High-Capacity Two Point Load Support

With dual load support points, the dock levelers provide high-capacity two-point load support and distribute the weight evenly, reducing stress on the other parts of the stress, which increases the overall structural integrity.

The attributes listed above make electric dock levelers a great choice for heavy-duty applications.

Corrosion Resistance and Weatherproofing

Electric dock levelers are built for extreme exposure and tough conditions while ensuring durability and long useful life. Their construction utilizes a combination of materials and protective features to shield them from corrosion and weatherproof them. It these features individually contribute to performance?

Galvanized Steel Construction

Almost all Electric dock levelers are made from galvanized steel, which gives them great defense from corrosion and moisture from the atmosphere.

Powder-Coated Finish

The enduring performance of a dock leveler is guaranteed by the additional protective layer provided by the powder-coated surface, which is resistant and corrosion from hooks and UV powders.

Sealed Electronics

Reliable operations of dock levelers are attained even in dusty or damp conditions due to the waterproof and sealed electric cover boxes, which protect them from dust, moisture, and other harmful materials.

Weather-Resistant Seals

Cost-effective and weather-durable seals protect the devices from damage due to water and decrease effective loss, ensuring they are protected from harmful factors.

Drainage Systems

Over time, sealed corroded dock levelers reduce the risk of moisture and critical parts due to the built-up drainage systems, which diminishes the risk of standing water.

Composing the electric dock levelers with these features makes them useful and effective for different weather conditions.

Load Capacities and Durability

Built for a variety of loading and unloading activities, electric dock levelers are maintained for their sturdy build and durability for lasting performance. Here are five of their load and endurance key details and metrics.

Heavy Duty Dock Levelers

For any materials that need to be light to moderately loaded and unloaded within a freight shipment, electric dock levelers do best with anywhere to 25,000 and 45,000 pounds of standard load capacities.

Steel Reinforced Construction

To consistently perform without added risk of malformation, the high-tension steel that makes electric dock levelers platforms and lips is made with aids in heavy usage wear and tear.

Dynamic Load Absorption

The inability of the electric dock levelers to withstand the dynamic load forces that forklifts generate is nearly impossible. This means plenty of dock and equipment protection over the years.

Service Life Expectancy

Coming in at a 10 to 15-year service life, the electric dock levelers do best under proper maintenance.

Corrosion Resistance

Reducing maintenance over the years, materials resistant to corrosion are useful in wet environments. It is these finishing coatings that enhance durability.

In all industrial environments, electric dock levelers prove to be reliable and perform exceptionally well.

Applications of Electric Dock Levelers

Warehouses and Distribution Centers

Within warehouses and distribution centers, electric dock levelers greatly improve operational workflows. They facilitate easy transitions between vehicles and loading docks, adjusting to different vehicle heights without any hassle. Users benefit because the loading and unloading process is faster, resulting in less downtime and better overall productivity. Most electric dock levelers now have safety features—anti-slip surfaces, safety lips, and automatic leveling systems—to mitigate the chances of an accident occurring during material handling.

In addition, the sturdy construction of levelers and their ability to endure wear and tear make them suitable for high-volume distribution centers. Warehousing systems gain from the perfect combination of electric dock levelers and systems that automate loading. This greatly improves workflow and material handling. Ultimately, electric dock levelers enhance productivity and safety in distribution centers and warehouses.

Food Processing and Temperature-Controlled Facilities

Docks need to be kept at certain temperatures to unlock sweet frozen food goodness, lest perishables go bad underneath. Electric docks fix this seamlessly, performing the magic of fusing trailer and dock while plugging up air holes to stretch air and preserve temp. The dock stays defrosted while the trailer stays frozen. With modern docks having hydraulics and auto systems, heat and contamination by air are eliminated, and temperature systems stay primed. Food can be loaded in and out at supersonic speeds, greatly enhancing productivity. Hygiene is increased, and regulations stay on point. The Electric Dock is the magic spell.

Retail and Commercial Buildings

By facilitating faster loading and unloading processes at docks, Electric Dock Levelers have greatly benefited the retail and commercial industries. Many of these businesses deal with high volumes of goods coming in and out; the need for high-quality and reliable dock access equipment is of utmost importance. Electric dock levelers ensure that there is a simple and easy connection for offloading and loading goods, whether from a building or a vehicle. Designed with features including, but not limited to, advanced safety features, easy push button controls, and ergonomic design, dock levelers minimize productivity losses and greatly reduce the time taken to offload goods.

In addition to these benefits, Electric Dock Levelers enhance the level of cleanliness in a commercial space. This is incredibly beneficial for retail businesses that deal with perishables or any other items that require a controlled environment for storage. Further, electric dock levelers are designed to be energy efficient; hence, businesses considering lowering energy expenditures while improving their business sustainability processes will surely benefit. Such electric dock levelers will ensure that businesses in retail and commercial sectors are able to keep up with tedious logistical processes while providing quality service to their customers.

Manufacturing Plants

Focus manufacturing plants need levelers to make the loading and unloading processes a lot easier and more efficient. Electric dock levelers are a great solution for easy and precise use in height adjustments for vehicles. While shipping and receiving dock use is highly constant, manufacturing facilities in use do need dependable equipment to close the gap between the shruk and loading dock. Activities carried out in a manufacturing setting which include the continuous movement of raw products, heavy equipment, and finished products, all need reliability in loading dock levelers.

Electric dock levelers reduce the amount of manual labor and the risk of workplace accidents, making workplace safety more efficient. With the ability to carry high-capacity heavy loads, these dock levelers are great for moving heavy industrial materials. These modern solutions do not just improve the logistics of a facility, though; they also provide. Electric dock levelers are a great example of meeting the requirements for workplace safety as well as the sustainable goals for the manufacturing facility. With robust durability and energy-conserving use, these levelers perfectly fit into the required high-paced environment of manufacturing plants.

Installation and Maintenance of Electric Dock Levelers

Professional Installation Guidelines

If you want an electric dock leveler to perform properly, last long, and remain safe, proper installation is a must. Listed below are factors to consider for professional installation:

Preparation for the Site

The site for installation must be uncluttered and clean.

Dock plit measurements must be accurate to be compatible with the dock leveler model.

Ensure the foundation is stable and is strong enough to support heavy loads.

Positioning the Leveler

Use suitable lifting equipment to carefully place the dock leveler in the pit.

Check the leveler’s alignment to determine if it is centered and if it is level and aligned with the pit.

Electrical Connections

Connect the dock leveler to the power source while observing electrical safety protocols.

Install circuit breakers or fuses in case there is a power surge, to protect the system from the surge.

Check and test the wiring connections to confirm that the system is functional.

Functionality Testing

Check to see if the leveler’s hydraulic or pneumatic system gives the ability for smooth operation.

The ramp and lip movement should also be checked to see if they can range the set motion.

The system’s safety features must also be checked to see if the emergency stop functions.

Safety Inspections

Check all the bolts, nuts, and fasteners to be sure that they are properly fastened.

Ensure that safety guards and warning labels are properly placed on the steel dock edge.

Ensure trainers provide appropriate instruction to their employees and authorized personnel on the correct operation and equipment safety procedures as outlined in the attached Operator Safety Manual.

The above requirements, if followed diligently, could improve both the productivity and safety aspects of the electric dock leveler in use. Like any piece of equipment, the electric dock leveler requires servicing, and the instructions provided with the installation must be followed to guarantee reliability.

Routine Maintenance and Troubleshooting Tips

For an electric dock leveler to operate at its finest, routine servicing and timely troubleshooting are needed. The list below comprises five main recommendations:

Inspect The Hydraulic Systems

Regularly check for leaks or broken hoses.

Replace hydraulic fluid every 6 to 12 months to avoid contamination and improper functioning.

Review The Electrical Systems

Inspect wiring for frays, looseness, and corrosion.

Periodically, check the control box and switches for proper functioning.

Lubrication Of Moving Parts

Use the correct grease on hinges and pivoting points as advised by the manufacturer.

Lubrication should be done at least every 30 days to minimize wear.

Monitor Dock Leveler Platform and Lip

Inspect the platform and lip of the hydraulic edge-o-dock leveler, looking for any signs of distortion, cracking, or structural damage.

Confirm that the lip smoothly operates extension and retraction.

Assessment Of Safety Features

Check that the emergency stop button and any other safety features are functional.

Confirm that the safety guards and labels are undamaged and are clearly highlighted.

By integrating the above maintenance techniques, you can avoid breakdowns, prolong your operational life, and enhance safety at your work sites.

Cost Considerations and Total Cost of Ownership

In order to assess the cost considerations and total cost of ownership of an electric dock leveler, one has to determine both the upfront investment and the operational expenses incurred after the leveler has been installed. Below are discussed five important contributors to the total cost.

Initial purchase price

This involves the bare minimum cost of the electric dock leveler and any additional features or modifications one may wish to make. They tend to go from $8000— $15000 but vary depending on the manufacturer, how much capacity the dock has, and its other specifications.

Installation expenses

These involve the services of professionals who need to be employed for the accurate installation of the dock leveler, which must include the proper functioning of the device. This charge also varies, but the standard charge for this type of installation goes from $1500— $3000.

Electricity expenses

This is an unavoidable cost that has to be incurred when using electric dock levelers. This charge varies depending on how much the device is used, but the average is somewhere between $300— $800.

Maintenance and repairs

These costs are necessary in order to make sure that the dock leveler stays in its ideal condition, as after a certain time, the device is bound to wear and tear. Average maintenance costs go from $200— $500, but repairs are often more costly.

Lifespan and Depreciation

The expected lifespan for properly maintained electric dock levelers is 10 to 15 years. Depreciation should also be included in the overall expense.

Analyzing these factors adds depth to the understanding of the expenses tied to owning and operating an electric dock leveler and assists businesses in making educated decisions during the purchase.

Safety and Compliance Features

Emergency Stop and Safety Interlocks

Electric dock levelers are equipped with various emergency stop and safety interlock features to enhance safety and prevent accidents during operation. Below are five critical safety features included in modern electric dock levelers:

Emergency Stop Button

Provides an immediate halt to all operations in case of an emergency.

Typically located within easy reach of the operator to ensure quick access.

Reduces the risk of accidents caused by malfunction or user error.

Safety Lip Barrier

Prevents forklifts and equipment from rolling off the edge of the dock.

Automatically deploys when the leveler is in a parked position for added protection.

Lockout/Tagout Capability

Allows maintenance personnel to secure the equipment and prevent unauthorized or accidental operation.

Ensures compliance with workplace safety regulations.

Overload Protection System

Prevents operations when the load exceeds the dock leveler’s capacity, protecting the system and users.

Includes sensors to monitor load limits in real time.

Hydraulic Safety Stop

Automatically freezes movement in the event of a hydraulic system failure.

Provides an additional layer of protection to avoid sudden drops or uncontrolled lowering of the dock leveler.

These advanced safety and compliance features are vital for ensuring efficient and accident-free use of electric dock levelers in industrial settings.

Compliance with OSHA and Industry Standards

Electric dock levelers are constructed and built to align with safety and operational guidelines, while ensuring OSHA compliance and associated industry regulations. The electric dock levelers comply with the requirements and guidelines highlighted below.

OSHA Standard 1910.26

This standard covers dock boards to be set, able to hold weight, and to be constructed and positioned to eliminate slipping.

ANSI MH30.3

Subordinate provisions for dock levelers, which include design, testing, and safety, and other provisions for structural and operational safety.

NFPA 70 (National Electric Code)

Provided safety for dock levelers with power components and cross with electric-wire powered components, ensuring safe electric wiring.

ISO 13849-1

Focusing on dock levelers for control system safety, this standard covers normal, fail-safe, and failure modes.

CSA C22.2 No. 14

Provided a system to comply with operating electrical performance standards for industrial or hazardous environments.

Compliance with the set standards enables electric dock levelers to facilitate safe loading dock operations, which enhance industrial operational efficiency and reliability while reducing safety hazards.

Innovations and Smart Technology in Electric Dock Levelers

Remote Operation and IoT Integration

Remote control functionalities, along with IoT (the Internet of Things) integration are new features being added to electric dock levelers. This new technology helps in controlling various dock operations. These dock levelers are connected to IoT technology, which in turn helps in monitoring and controlling these dock levelers remotely. This helps keep track of performance, maintenance, and reduced dexterity in dock operations. This enables facility managers to control dock levelers from a single place, which improves the workflow with less need for manual control.

Remote operation comes with many benefits, such as IoT, which helps in prognostic maintenance using sensors on equipment and monitoring patterns in equipment usage, such as wear and tear. What is more is that with IoT features such as automated monitoring systems, operations are much safer when paired with the ability to halt systems when unsafe conditions are met. Multi-site businesses utilize cloud systems which optimize dock systems for maximized operational deployability and conformity across various sites. These benefits illustrate the improvement of smart technology in the dock levelers, using new technology to significantly reduce operational costs while still satisfying the new standards of fast-paced operational environments.

Predictive Maintenance Features

Predictive maintenance is revolutionizing the way electric dock levelers are monitored and maintained, offering businesses a proactive approach to equipment management. By utilizing sensors and advanced analytics, these systems can analyze operational data in real time to predict potential issues before they result in costly downtime. Key features include predictive diagnostics, which monitor wear and tear on critical components, and automated alerts that notify operators of maintenance needs. Integration with IoT platforms allows for seamless data collection and cloud-based analysis, enabling fleet-wide insights for multi-location operations. With the latest advancements, businesses can reduce repair costs, extend equipment lifespan, and maintain the safety and reliability of their dock levelers, ensuring uninterrupted logistics and operational efficiency.

Energy-Efficient and Eco-Friendly Options

Modern electric dock levelers have been optimized for energy-efficient and sustainable designs, addressing environmental concerns and saving costs for businesses. State-of-the-art energy-efficient components like high-efficiency motors and low-power standby modes reduce electric energy consumption. Moreover, manufacturers practice environmental concerns and eco-friendly production by using low-VOC coating, among other things, and using recycled steel.

Regenerative hydraulic systems, as well as other mechanical systems designed for energy recycling, range among the most recently developed innovations. Some electric dock levelers integrate smart control systems that use real-time data to manage energy optimally. Besides reducing carbon footprints, these eco-friendly solutions achieve clean and green logistics, which is essential for the global sustainability goals. Investing in energy-efficient dock levelers has the added advantage of reducing energy expenditure and, at the same time, serving the wider sustainable practice, which is increasingly necessary for businesses in the modern market.

Comparing Electric Dock Levelers to Other Leveling Solutions

Electric vs. Hydraulic and Mechanical Dock Levelers

Electric (electric-hydraulic) dock levelers offer fully automated, push-button operation with high throughput and advanced safety features, but come with a higher upfront cost and require electrical power and more complex maintenance, whereas hydraulic and mechanical levelers cost less initially and have simpler systems but demand more manual effort (particularly mechanical), slower cycles, and greater labor/maintenance over time.

| Key point | Electric Leveler (Pros / Cons) | Hydraulic/Mechanical Leveler (Pros / Cons) |

| Operation | Push-button, automatic lip extension/return. | Hydraulic: button-control; Mechanical: manual chain/lever pull. |

| InitialCost | Higher due to motor, controls, and electrical setup. | Lower upfront (mechanical lowest), especially for light use. |

| LaborEffort | Minimal operator effort, safer ergonomics. | Mechanical high effort; Hydraulic low effort, but less than mechanical. |

| Maintenance | Needs upkeep of both electric + hydraulic components; somewhat higher complexity. | Mechanical: many moving parts, springs wear; Hydraulic: fewer parts, lower maintenance. |

| CycleSpeed | Suitable for high-volume, high-cycle operations. | Mechanical slower; Hydraulic good, but may lack full automation of electric type. |

| PowerReq | Requires a reliable electrical supply and installation. | Mechanical: no power; Hydraulic: needs power but fewer systems than the electric version. |

| BestUse | High-traffic, heavy-duty docks require full automation scenarios for smooth and efficient loading processes. | Mechanical: low-traffic, budget sites; Hydraulic: moderate/high-traffic without full automation needs. |

Pros and Cons for Different Facility Needs

Electric dock levelers are widely recognized for their efficiency and advanced automation features, making them an excellent choice for many modern facilities. Below are some key pros and cons of electric dock levelers based on their suitability for different facility needs:

Pros:

High Effectiveness: Electric dock levelers have pinpoint operations and swift movements, thus cutting down on load and unload times. As a result, they are a perfect solution for a facility that has plenty of traffic.

Seamless Automation: With the deployment of tailor-made sophisticated control systems, electric dock levelers can interact and operate in sync with other systems within the warehouse, hence enabling full automation and advanced workflow processes.

Reliability, Sustainability: Electric dock levelers are built and constructed in high-grade materials combined with sturdy engineering work, and they can withstand heavy and continuous usage in demanding operations.

Improved Safety: Most of the electric dock levelers have the stilling control of the stage, enabling an enhanced holding mechanism of the lip. Also, the dock slip platforms, emergency control, and reinforced lip stability are vital for a safe working area.

Eco-Friendly Energy Saving Innovations: Some new electric models are fitted with motors that consume a smaller amount of energy and have a standby mode for cutting down on unnecessary energy expenditure.

Cons:

More Complete Spending: Compared to other types of hydraulic and mechanical dock levelers, electric dock levelers cost more up front because special technology and innovative automation systems are used.

Dependable on Power: Electric dock levelers are not a good fit for a facility that deals with frequent outages and utilizes power more due to an unreliable energy infrastructure.

Difficult to Maintain: Electric dock levelers come with advanced technology, and because of that type of reasoning, it’s systems are likely to incur more expensive fundamental expenses, which translates to higher repair and ease of use costs that come over the course of time.

Less Portability: Electric dock levelers are not as good as other types of levelers because they are not adaptable and therefore, scaling dock configuration and construction are stiff challenges.

When optimizing for electric dock levelers, it’s a juxtaposition of determining if enhanced automation with ultra-safe electric dock levelers at a certain desired cost is worth the energy they demand. Businesses in lower retrofitted areas benefit more than traditional electronic models. Electric dock levelers benefit high-end and advanced bolt areas with unmatched performance.

Market Trends and Future Outlook

Growth in Automated Loading Dock Solutions

Rapid technological progress and an increase in demand for efficient logistics operations and automation in all sectors have positively impacted the demand for electric dock levelers. Over the years, the installation of electric dock levelers has exponentially accelerated in e-commerce, warehousing, and manufacturing sectors. In e-commerce, warehousing, and manufacturing sectors in particular, the demand for automation has led to the deployment of advanced, productive programmable electric dock levelers and systems. Such dock levelers and systems implement state-of-the-art, sophisticated, advanced, productive, programmable electric dock levelers.

The levelers have advanced programmable and multifunctional controls to enhance the operational efficiency and functionality. In an effort to increase operational efficiency, multifunctional electric levelers implement state-of-the-art, sophisticated, vitally needed, and essential features such as programmable, advanced, sophisticated, productive multifunction systems, and charge-sensing capabilities, along with multifunction electro-sensitive charge detection and systems. Moreover, programmable levelers have systems and capabilities to implement advanced, sophisticated remote vitally needed operations, monitoring, suppression, and maintenance. In addition, decreasing energy and operational maintenance are vitally needed and essential charges, along with eco-sensitive operational models and programming, have led to programmable dock levelers achieving green building standards.

The future outlook for electric dock levelers looks bright. They are expected to evolve technologically and meet the growing needs of the industry. Benchmarks will likely be set by innovations like IoT and its integration into diagnostic platforms, machine learning algorithms for real-time diagnostics, and configurable platforms to accommodate any type of docking. The expected advancements indicate that electric dock levelers will become a pivotal part of fully automated, data-driven logistics systems.

Leading Brands and Recent Product Innovations

The following are five of the most prominent companies in the electric dock leveler business and their newest products and innovations:

Blue Giant

Recent Innovation: Edge-of-Dock Electric Leveler Series

Highlights: Designed for high-volume dock operations, this model comes equipped with the capability of push-button operation as well as the ability to return to the dock automatically, conserving battery power.

Rite-Hite

Recent Innovation: RHH-300 Hydraulic Dock Leveler

Highlights: Most recognized for their comfortable and easy-to-use design, this model comes standard with great safety features, which are automatic safety stops and advanced hydraulic control systems for smooth leveling.

Kelley Entrematic

Recent Innovation: HydroCarnival Electric Dock Solution

Highlights: Able to work with various warehouse and vehicle configurations because of the German hydraulic systems and customizable platforms, this product is one of the most versatile dock solutions on the market.

Serco

Recent Innovation: UltraSync Smart Dock Levelers

Highlights: Thanks to the IoT-enabled monitoring and diagnostics features, this product allows warehouse managers to track the functionality of their systems in real time, which in turn minimizes downtime and maximizes efficiency.

Pioneer Dock Equipment

Recent Innovation: ProDock Electric Series

Highlights: Outstanding in an electric dock environment, this series comes with low-maintenance features, effortless installation, and reliable safety features for use in harsh conditions.

With this pursuit of innovative technology and high usability in dock levelers, the electric dock leveler market has the greatest adjustable and versatile options.

Conclusion: Choosing the Right Electric Dock Leveler for Your Facility

Key Decision Factors for Facility Managers and Owners

It’s very important to consider several specific categories when choosing an electric dock leveler to suit your facility. These decision points assist in fulfilling your operational workflows while improving your level of safety and productivity. The following five points tackle the most defining criteria to help shape your decision-making:

Primary Factor-Weight Capacity

An electric dock leveler will be useless if its weight limit doesn’t accommodate the most basic vehicles, equipment, and cargo that your line of work uses. The average for most electric dock levelers will be between twenty thousand pounds to eighty thousand pounds. Facilities that operate on heavy-duty tasks should consider the use of high-capacity models, as this will save on wear and tear while providing reliability.

Factor Durability and Material Build

To provide the most reliable and cost-efficient electric dock levelers, the most basic components should be high-tensile steel and reinforced parts. If your facility operates in areas that have high environments, heavy use, and harsh conditions like extreme temperatures, be sure to provide equipment that has been accurately tested.

Factor three- Energy Efficiency

Like any modern appliance, electric dock levelers add on to facility utility costs; therefore, all tied to energy usage. It is vital to seek models with motors that save energy, advanced systems, and the capacity to auto-shutdown, schedule to turn off the usage, all at the base level of performance.

Safety Features

While operational risks are omnipresent, automatic fall protection, anti-skid platforms, and even emergency stop devices help minimize these risks. Advanced Safecork devices are crucial in high-volume activity environments or wherever dock levelers are frequently utilized.

Ease of Maintenance and Serviceability

Look for dock levelers with self-diagnostic control, modular parts for rapid repair and replacement, and readily accessible service points. Such features help in greatly improving operational efficiency and lowering delays.

Evaluating all these aspects helps logistic managers and owners streamline their decision-making. It ensures that the intended electric dock leveler facilitates unobstructed daily activities and satisfies the business logistics needs.

Final Recommendations for Efficiency, Safety, and ROI

In my opinion, when selecting the most suitable Electric Dock Leveler, one has to emphasize efficiency, safety, and roi. It is prudent to consider models that offer robust construction, low operational energy costs, and sophisticated safety provisions so that hydraulic failing and other locking safety systems can be bypassed. It would also be wise to assess the maintenance requirements so that the servicing stays within the acceptable limits, the downtime is minimized, and the operational costs for the lifetime of the asset are prudent enough to provide the necessary ROI. Integrating the attractive factors into the operational equilibrium enhances decision-making confidence as well as practicality.

Frequently Asked Questions (FAQs)

What are electric dock levelers and how do they work?

Electric dock levelers serve as pieces of dock machinery that enable the effortless movement of cargo between trucks and a loading dock. With the help of electric hydraulic systems, the dock levelers can raise the deck to a certain level for optimal loading and unloading. As such, the levelers can adapt to varying dock and truck bed heights, giving a gentle and productive loading experience.

What is the service range of electric edge-o-dock levelers?

The range of electric edge-o-dock levelers varies due to the model and manufacturer, Vestil, for example. These models are able to resolve the height difference between a truck and a loading dock of 5 to 12 inches. Look at the levelers’ functionality and compare it to your loading dock to be certain it fits within your operational needs.

What are the benefits of hydraulic dock levelers for high usage dock areas?

The push of a button activates hydraulic dock levelers that are very useful at busy loading and unloading docks. Due to the frequency of loading and unloading, their design yields exposure to wear and tear and state-of-the-art hydraulic systems. These levelers help smooth busy schedules with their rapid wear of dependability.

How does an edge-o-dock leveler function?

Edge-o-dock levelers serve as a bridge between the dock and the truck bed. When the operator holds down and pushes the control button, the leveler deploys to form a safe loading surface. Many models have a bumper that protects the dock and truck from damage, making the loading process smooth.

What are the product specifications for electric hydraulic dock levelers?

Product specifications on electric hydraulic dock levelers often include platform size, height range, and weight capacity. An example of a common specification would be a ramping length of 66 inches and a weight-holding capacity of 30,000 pounds. Always refer manufacturer’s details for respective models to ensure your levelers match your loading dock.

Can hydraulic dock levelers be activated automatically?

Correct, some hydraulic edge-o-dock levelers can be set to operate on their own, as these specific models tend to have sensors that “see” the truck and deploy the leveler, which improves safety and efficiency. This is especially important for loading docks with high volume.

What is the advantage of vertical storing dock levelers?

Retractable vertical storing dock levelers save space because they fully retract into a stored position. Space saving is very important for facilities with limited dock space or that wish to optimize their loading zones. It is also helpful that this configuration greatly reduces the likelihood of accidental damage to the leveler and dock equipment.

Is a ramp required for the proper operation of edge-o-dock levelers?

Yes, an approach ramp is almost always a necessary component for the smooth operation of edge-of-dock levelers. This ramp enables the leveler to synchronize seamlessly with the truck bed. Correctly positioning the ramp will reduce the likelihood of loading accidents and help speed up the overall loading efficiency.

What maintenance is needed for electric dock levelers?

Electric dock levelers routinely have their hydraulic pump and associated plumbing for all leaks, the control button to ensure it opens, and the edge of the dock and leveler cleaned of debris. Best practices from the manufacturer will ensure dock levelers last for many years.

Reference Sources

- Texas A&M University Repository: A study on bed levelers and their operational impacts, which may provide insights into leveling technologies. Link to source.

- Naval Postgraduate School Repository: A comparative analysis of cargo handling operations, including electric systems in loading docks. Link to source.

- Academia.edu: Analysis of design faults in refrigerated warehouses, discussing dock leveler designs and electrical considerations. Link to source.